Oil and water don’t mix, is an old proverb. However it is also not easy to separate these two disparate substances in a wastewater treatment plant.

Any business/factory that has oil in its wastewater needs an oil water separator to make its wastewater compliant with the prescribed standards. Some of the businesses that require an oil water separator are: petroleum industry, metal working industry, food industry, mechanical workshops, service stations, transport depots, mining and construction sites, etc.

There are two forms of oils generally found in wastewater-

One being emulsified oil, which has been subjected to a certain amount of mechanical action before being dispersed into wastewater, this oil does not float thereby requires sophisticated treatment techniques.

Other form is the non-emulsified oil that floats on the surface of wastewater and can be easily removed.

Choosing the right oil water separator will be a bit complex. There is no cause for alarm.

This blog will guide you through everything you need to know about oil water separators particularly parallel plate gravity separators and hydrocyclone water oil separator.

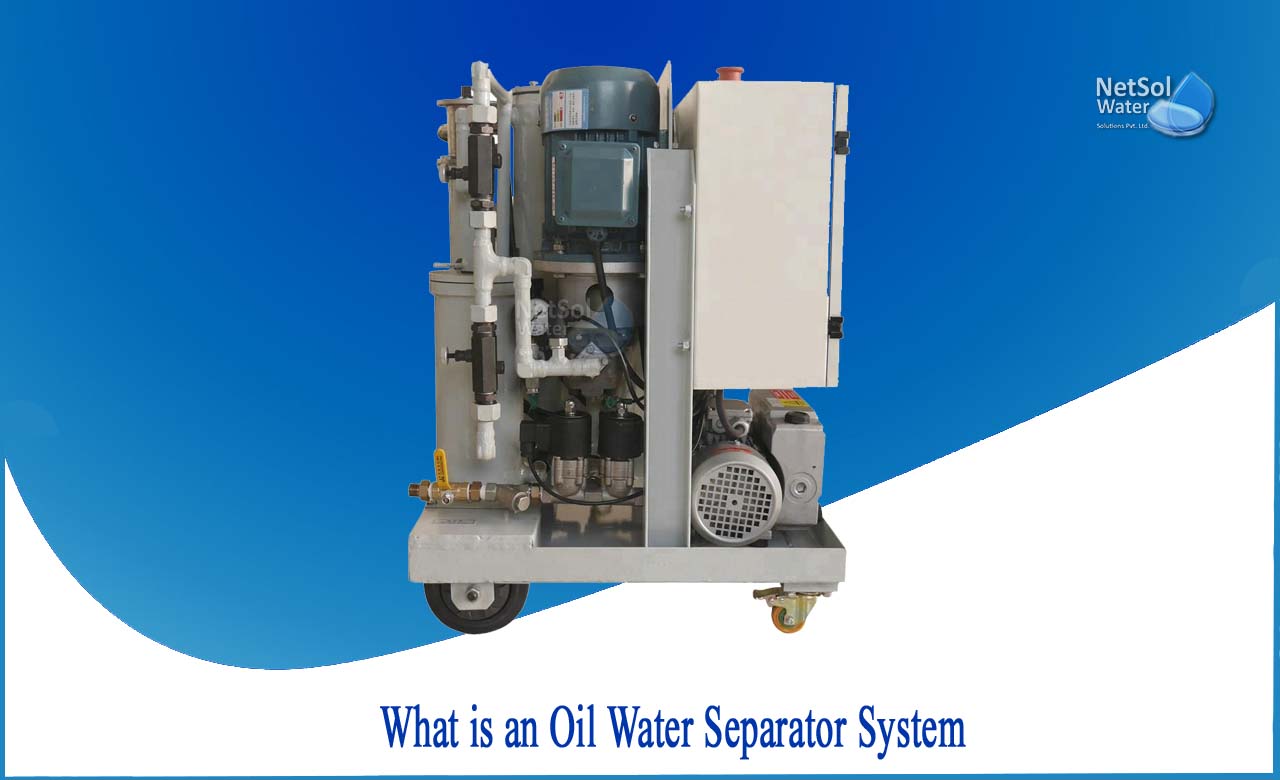

What is an oil water separator system?

An oil water separator is a piece of equipment used to treat wastewater by removing oils, grease and hydrocarbonsin industrial or commercial locations or at places where water could get contaminated with oil. It is based on separation and differences in density.

Oil water separators are specifically designed to target oil which rises to the top, heavier sludge settles to the bottom leaving wastewater in the middle layer.

Applications of Oil water separators

Oil and water separators are used in many industries from petroleum to food industry to transport and metal manufacturing to mining and wastewater treatment. These separators efficiently help in the removal of gasoline, diesel, and crude vegetable oil.

Types of oil water separators

The comm?on types of oil water separators are:

Conventional gravity separators, parallel plate gravity separators, hydrocyclone water oil separator system and floating separators.

Difference between parallel plate gravity separator & hydrocyclone water-oil separator system

1: Parallel plate gravity separator

In this type of oil water separator system, corrugated plates made of an oleophilic material are placed parallel to one another in a tank with a space of about 6-12 millimeters between them. Water and oil are then allowed to flow through the tank and in between these parallel series of plates. The oil in the water gets stuck on the plates. As more and more oil droplets attach, they form larger droplets and eventually rise to the surface where they are skimmed off and subsequently discharged in an oil tank. The remaining water is allowed to continue flowing through the tank and into a clean water outlet, where it can then be released for other uses.

These are designed by Stokes Law principles to define the rise velocity of oil droplets. It is decided on the basis of their density and size. This design includes inclined plate assemblies. The underside of each parallel plate provides more surfaces for suspended oil droplets to coalesce into larger globules. Parallel plate separators may not be effective in situations where water chemicals or suspended solids prevent oil droplets coalesce. In actual practice, the sediment adhere to the plates requiring periodic removal and cleaning.

2: Hydrocyclone water-oil separator system

A hydrocyclone is a mechanical device designed to separate oil particles from wastewater, by means of centripetal forces or centrifugal forces within a vortex. The primary construction of a hydrocyclone will normally have a cylindrical section at the top where liquid is being fed tangentially and spun at centrifugal forces of up to 1000 times the gravity force, and a conical base. The angle and length of the conical section, plays a role in determining operating characteristics.

A hydrocyclone water oil separator system uses an active vortex created when water contaminated with oil is injected at an angle into the tank. Since water is denser than oil, it is forced to the outer edges and allowed to fall towards an outlet located at the narrow conical end.

The lighter oil phase migrates towards the center and upwards through the top of the cyclone chamber into a used oil tank. This type of separator is ideal for highly efficient oil removal for industrial and commercial applications of large quantities of water.

Conclusion

Get in touch with our experts to have a complete knowledge about the type of oil water separator best suitable for your business establishment. We have solution for all your problems and a product for your every need.

Netsol water, wastewater and waste management experts will treat your system and proactively respond to your needs like they’re our own. Our mission is to make the world’s waste management systems affordable, sustainable as well as energy efficient.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.