Overview

Since the late 1980s, about 20 ecosystem sewage treatment plants have been built, from small-scale systems for individual schools to medium-sized municipal systems for thousands of households and industrial waste treatment systems for treating specialized wastewater streams.

It is very attractive to use the natural circulation of plants and animals for wastewater treatment instead of chemicals and mechanical systems. Traditional wastewater treatment systems already rely on bacteria for much of their work, but these organisms generally perform very limited functions within mechanical systems. Ecological technology brings more highly developed flora and fauna and provides an attractive and educational alternative to wastewater treatment.

What is ecological wastewater treatment?

All sewage treatment facilities rely on living organisms to break down biological and chemical waste. Traditional sewage treatment plants use concentrated bacteria to partially decompose waste in many aeration tanks. Then, various chemicals are used to settle the sludge and disinfect the wastewater.

Ecological wastewater treatment plants work in ways that are in a general sense similar but utilize exceedingly varied biological systems with a wide extend of organisms, like algae, oceanic plants, swamp plants, worms, shellfish, mollusc’s, and vertebrates—supporting the populaces of microscopic organisms that break down squanders and dispose of supplements from the wastewater. This environmental community makes the frameworks steadier within the confront of sudden dosages of intensely sullied water, known as shock flows.

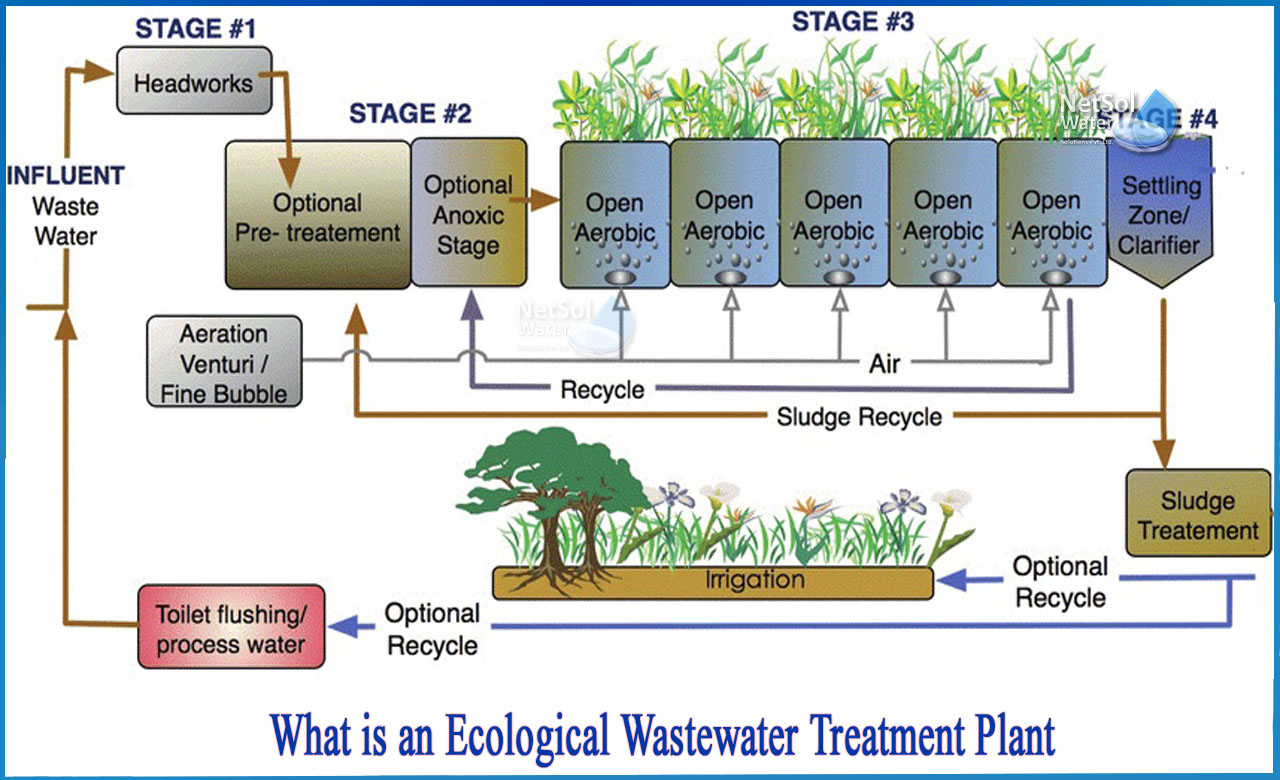

Raw sewage flows from the expansion tank into the system, where sand accumulates and bacteria are "sown" in the sewage to stimulate biological activity. This stage can be part of an ecosystem, or part of a larger traditional facility where the ecosystem draws wastewater.

Depending on the strength of the wastewater, the anaerobic reactor may or may not be used for pre-treatment. From here, wastewater flows through a series of ventilated reactor tanks or silos. These tanks are connected in series with wastewater that flows one after another by gravity. These series tanks typically have several parallel trains to increase dwell time and provide redundancy in the event of a failure. Each tank has a mini-ecosystem with a layer of aquatic plants floating on top (often supported by a mesh net).

The extensive root system of these plants spreads into the water and provides a habitat for bacteria that do most of the work of breaking down waste. The tank also supports algae, small crustaceans, snails and higher animals. Tanks later in the wash series are usually designed for higher organism ecosystems, including vertebrates.After treatment in series of tanks, water flows into the purifier, where solids accumulate as sludge. Some of these solids can be removed and used to inoculate incoming wastewater with bacteria. The rest is removed for storage, composting, or land use.In EEA plants, the clarified water flows into a subsurface-flow constructed wetland (passing through a sand filter first in some facilities). The wetland maintains an anoxic environment in which anaerobic bacteria remove nitrogen from the water.

Ecological sewage system performance:

Biochemical oxygen demand is one of the most common purity measurements. It is a measure of the amount of oxygen removed during the decomposition (oxidation) of organic matter in water, measured in milligrams per litre over a specific number of days.

BOD-5 refers to oxygen demand for 5 days. The higher the BOD, the more damage to the natural ecosystem that depends on dissolved oxygen in the water. According to the Environmental Protection Agency (EPA), the BOD-5 content of typical municipal wastewater is 200-290 mg/l, but the value can be significantly higher if waste from waste disposal is included. Ecological sewage systems are generally effective in reducing BOD and related ones, but are more permanent.

Chemical oxygen demand another indicator of performance is the removal of nutrients. Wastewater is high in both nitrogen and phosphorus. Nitrogen is removed through the biological processes of nitrification and de-nitrification. In the first stage, aerobic nitrifying bacteria convert ammonia into nitrite and nitrate. In the second stage, anaerobic denitrifying bacteria convert nitrates to molecular nitrogen (N2) and release it into the atmosphere. Some carbon is needed at this stage, but at this point almost all of the naturally occurring carbon has been removed from the river.

Environmental system designers are experimenting with a variety of low-tech additive carbon sources, but so far, the only cheap and reliable solution is the same chemistry used in traditional sewage treatment plants. The process, the addition of methanol. The use of methanol is due to the discovery that more organic carbon sources are being utilized and that these systems are superior to traditional treatments in nitrogen removal.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.