Introduction

Biological wastewater treatment (anaerobic and aerobic digestion reactors) takes advantage of certain microorganisms' (including bacteria's) ability to assimilate organic matter and nutrients dissolved in water for their own growth, thereby removing soluble components from the water. Microorganisms use soluble organic matter as a carbon source. Following this operation, the biomass derived from the supernatant is separated by decantation. Nitrogen and phosphorus, as well as organic matter, are required in the effluent for microorganisms to grow.

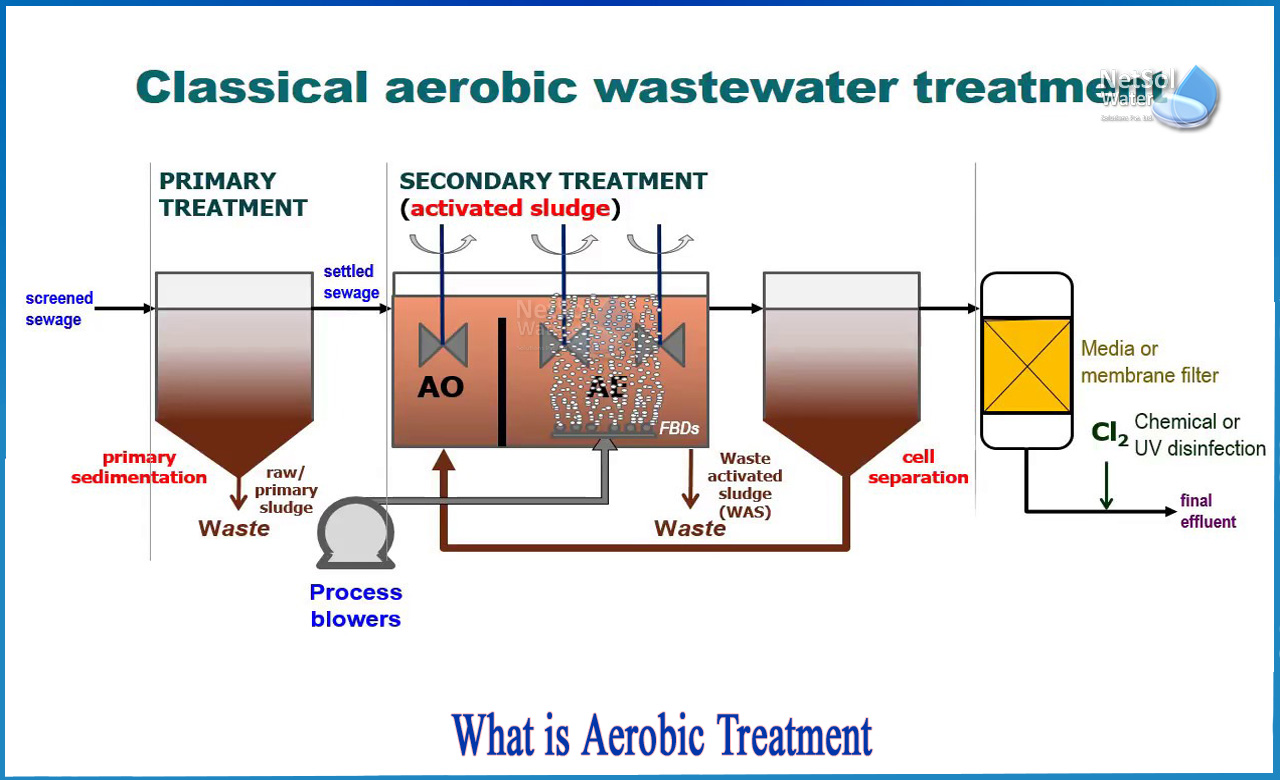

What is aerobic treatment?

Aerobic treatment is a type of biological wastewater treatment that occurs in the presence of oxygen. Aerobic biomass breaks down organics in wastewater to produce carbon dioxide and new biomass.

Aerobic treatment technologies can be used to polish an aerobically pretreated wastewater to remove biochemical oxygen demand (BOD) and total suspended solids as stand-alone systems for treating raw wastewater (TSS). Aerobic technologies can also be used to remove nitrogen and phosphorus as a biological nutrient removal system (BNR).

Aerobic treatment is better suited to low-strength wastewaters, whereas anaerobic treatment is better suited to high-strength wastewaters. Each of these processes has a number of advantages and disadvantages that are well documented. Many variations exist in the form of combined operations involving both aerobic and anaerobic treatments in order to maximize the impact. One variation involves sequencing the two methods, recycling sludge, and optimizing the benefits of both operations, resulting in better-treated water quality and lower sludge generation. It should be noted that such sequencing can be extremely useful when one fraction of the wastewater can only be degraded aerobically and the other can only be degraded an aerobically.

Stages of Aerobic Treatment

1. Pre-treatment

Large solids are removed first at the water treatment plant. These materials, if not properly disposed of, can cause serious equipment failure. Stones, sand, tin cans, and other debris cause significant wear on pipes and pumps.

Oils and fats are also removed at this stage to prevent the biological treatment from slowing down as the effluent's performance and quality deteriorate. This is accomplished through the use of both physical and mechanical operations. The following are the main operations used, which are dependent on the wastewater source, its quality, and subsequent treatment:

· Large solid?s separation: This system is used when the water to be treated contains large solids. It consists of a pit at the collector's entrance that concentrates solids and decants sand to a specific area where it can be extracted effectively.

· Gross filter: This operation prevents large solids from obstructing later stages of the process. It is made up of bars with varying distances between them that are used to separate solids based on their size.

· Scre?ening is required when wastewater contains a high concentration of floating solids or debris. Sieves of various thicknesses are used.

· Desander: Used to remove solid particles larger than 200 microns that can clog pipes or pumps and scratch or damage various pieces of equipment.

2. Primary Treatment

Various physical and chemical processes are used at this stage to remove suspended solids from the water. These solids can be sediment able, floatable, or colloidal in nature.

· Sedimentation: Gravity separation results in particles denser than water settling at the bottom of the settler. The higher the sedimentation velocity, the greater the size and density of the particles to be separated in the water, and this is the main design parameter for this equipment. Decantation is another term for this sedimentation process. Primary decantation removes suspended solids (approximately 60%) and organic matter (30% approx.) while protecting subsequent biological oxidation processes from the intrusion of inert, high density sludge.

· Floatation: This process separates solid or liquid matter that is less dense than the fluid and rises to the surface due to a difference in densities. Air is used as a flotation agent, and there are two flotation systems based on how it is introduced into the liquid: Dissolved Air Flotation (DAF), which introduces air into the wastewater under several atmospheres of pressure, and Induced Gas Flotation, which produces gas bubbles via diffusers.

· Coagulation – Flocculation: When very small particles are present, electrical interactions between them form highly stable colloidal suspensions, and their sedimentation rate is slow. To improve their removal, chemical reagents are added to destabilize the colloidal suspension (coagulation) and promote flocculation of the particles, resulting in easily settleable particles. Coagulants are typically chemicals in solution with an opposite electric charge to the colloid.

· Filtration: To retain as much of the suspended material as possible, the water is filtered through a porous medium. A bed of varying heights of sand has traditionally been used as a porous medium.

3. Secondary Treatment

This is based on biological processes that employ microorganisms (particularly bacteria) to remove biodegradable organic matter, both colloidal and dissolved, as well as nutrients (compounds containing N and P). Organic matter is typically oxidized by microorganisms that use it as a source of energy for growth.

Aerobic processes work by converting organic pollutants into bacterial biomass with the help of oxygen (which acts as an electron acceptor in the oxidation process), CO2, and H2O.

In aerobic systems, wastewater is routed through an aerobic reactor-digester containing microorganisms that oxidize dissolved organic matter via an oxygen flow.

4. Tertiary treatment

Tertiary treatment may be used to remove residual organic load and other pollutants not removed by secondary treatment, such as nutrients, phosphorus, and nitrogen, depending on the quality of the effluent obtained, its final destination, and applicable legislation. Any combination of treatment processes, whether physical, chemical, or biological, can be used.

In general, they are:

· Microfiltration and ultrafiltration.

· The exchange of ions.

· Reverse Osmosis.

· Adsorption.

· Membranes.

· Disinfection- This entails removing or inactivating pathogenic or other living microorganisms so that the treated water can be reused.

The following are the primary disinfection processes:

· Chlorination

· Ozonation

· Electro disinfection

For more information, contact Netsol Water.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.