Overview

Traditional activated sludge systems are frequently used in sewage treatment plants to treat wastewater biologically. Due to the sludge's poor settling qualities, these systems often require vast surface areas for treatment and biomass separation units.

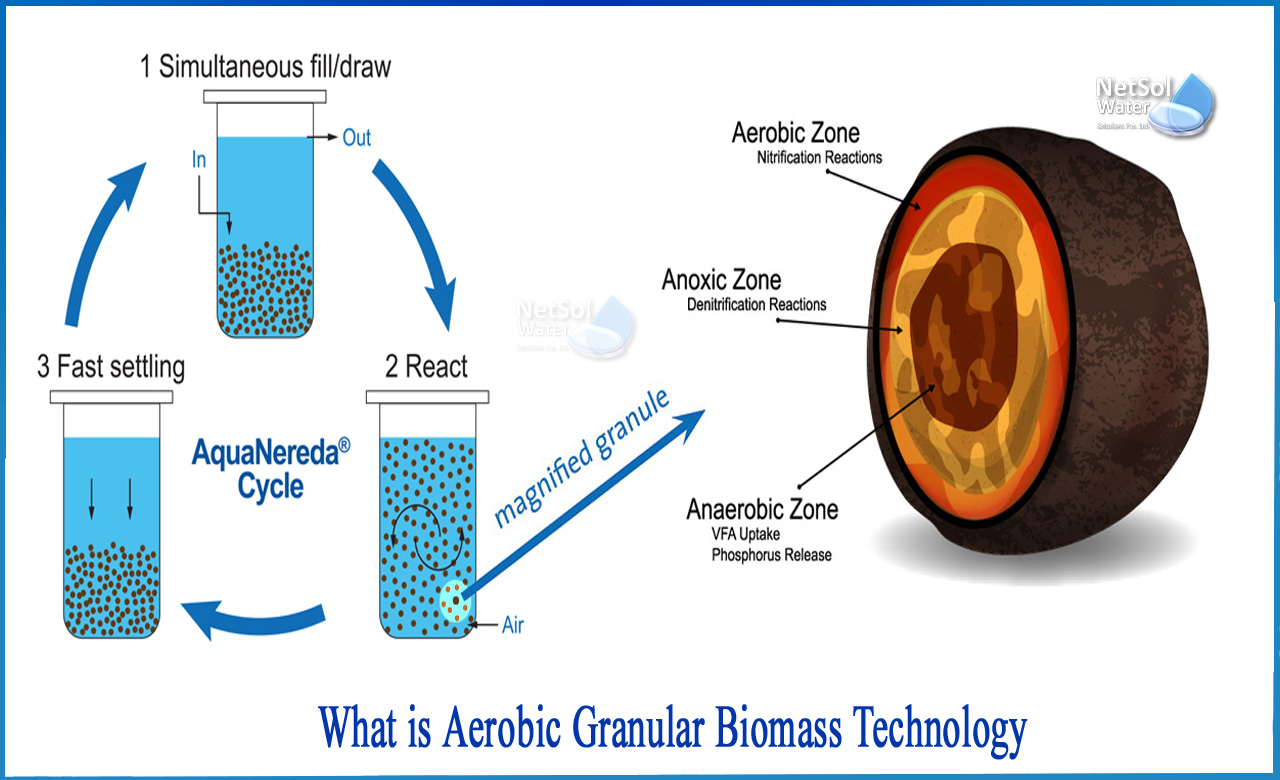

What is Aerobic Granular Biomass Technology?

Aerobic granules are a form of sludge that has the ability to self-immobilize flocs and microorganisms onto spherical, robust compact structures. High biomass retention, simultaneous nutrient removal, excellent settleability and toxicity tolerance are all advantages of aerobic granular sludge. Aerobic granular sludge treatment may be a viable option for treating high-strength wastewaters including nutrients and hazardous compounds.

The aerobic granular sludge is typically grown in an SBR (sequencing batch reactor) and used as a wastewater treatment for high-strength wastewater, hazardous wastewater, and household wastewater with great success. In comparison to traditional aerobic granular COD removal procedures, current research focuses on simultaneous nutrient eliminating, notably COD, phosphorus, and nitrogen, under pressure circumstances such as high salinity or thermophilia.

New technologies have been developed in order to further improve settleability. One of them is the use of aerobic granular biomass technology.

Formation of Aerobic granulation

In sequencing batch reactors (SBRs), granular sludge biomass is produced without the use of carrier materials. The majority of the prerequisites for their formation are met by these systems, including:

>Short feeding durations must be chosen to induce feast and famine periods, which are distinguished by the presence or absence of organic materials in the liquid media, respectively. This feeding technique allows for the selection of the right microorganisms to create granules. Granule-forming organisms have an advantage over filamentous organisms when the substrate concentration in the bulk liquid is high because they can store organic materials in the form of poly—hydroxybutyrate to be ingested during the famine period. This component is strengthened when anaerobic feeding is used, reducing the value of a short settling period and larger hydrodynamic forces.

>Short settling time: The microbial population is subjected to hydraulic selection pressure, which permits granular biomass to be retained inside the reactor while flocculent biomass is washed away.

>The use of large shear forces promotes the production of aerobic granules and the physical granule integrity, according to evidence. It was discovered that aerobic granules could only be created above a threshold shear force value in terms of surface upflow air velocity above 1.2 cm/s in a column SBR, and that high hydrodynamic shear forces resulted in more uniform, round, and compact aerobic granules.

Benefits of Aerobic Granular Biomass Technology

The use of biomass in the form of aerobic granules in the extraction of organic matter, nitrogen, and phosphorus compounds from wastewater is being investigated. When compared to a traditional activated sludge process, aerobic granules in an aerobic SBR offer various advantages, including:

1: Stability and flexibility: The SBR system is adaptable to changing conditions and can endure stress and hazardous loadings.

2: Low energy requirements: The aerobic granular sludge process has a greater aeration efficiency due to the increased height of operation, when there are no return sludge or nitrate recycle streams, as well as no mixing or propulsion requirements.

3: Reduced Footprint: Increase in biomass concentration is only possible due to the quick settling velocity of the aerobic sludge granules and the lack of a final settler, results in a significant reduction in the required footprint.

4: Good Biomass retention: Thanks to good biomass retention, higher biomass concentrations inside the reactor can be reached, and higher substrate loading rates can be treated.

5: Presence of aerobic and anoxic zones inside the granules: Since the granules contain aerobic and anoxic zones, the system can perform multiple biological processes at once.

6: Decreased capital and operational costs:The cost of operating an aerobic granular sludge wastewater treatment plant can be reduced by at least 20%, and the amount of space required can be reduced by up to 75%.

Netsol Water is working on such advanced technologies to make treatment more effective.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.