What is Aeration Tank in water treatment?

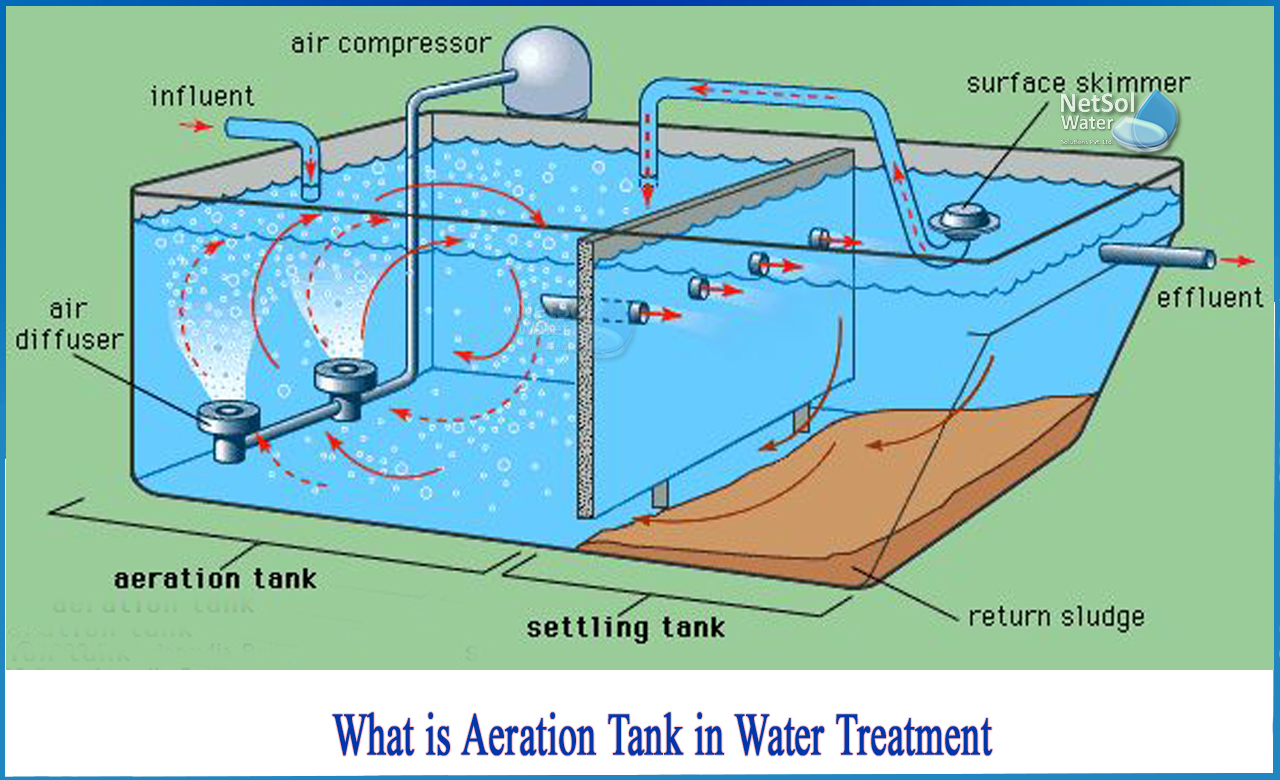

The bio media is suspended in water and agitated by aeration in the aeration tank. Aeration is provided by fine bubble diffusers installed in groups at the tank's bottom. Bio-mass growth on the biomedia aids in the break - down of contaminant which results in clean water. A baffle is installed near the tank's inlet to assist in settling and to prevent sewage from just being short-circuited. The inlet and outlet pipes are the furthest apart from one another.

Where is aeration provided?

Aeration takes place in cycles to allow for nitrification and de-nitrification cycles. A nearly 7-foot free board is made available to engage with any accidental overloading of incoming sewage. The tank's outlet is covered by a mesh to help stop biomedia from escaping. The tank's inlet is protected by mesh.

How to ensure maximum retention?

The sewage from the raw sewage lift pump is routed through the inlet pipe (sewage from the equalisation tank). The pipe is bent downward to prevent sewage from flowing into the outlet pipe.

The baffle wall prevents incoming sewage and sludge from flowing across the tank toward the outlet pipe. The wall compels the mix to the tank's bottom, providing optimum retention.

The tank is always filled to this level (which is determined by the launder's top). As a result, the tank's remaining height serves as freeboard (height margin to ensure that the tank does not overflow immediately under moderate emergencies.)

What does Outlet Launder collect? And where is Outlet launder located?

The Outlet Launder collects and transports sewage to the outlet pipe. It is important to note that the outlet launder is located farthest away from the inlet pipe to avoid short circuiting of flow from the tank's inlet to its outlet.

The net prevents debris from entering the outlet pipe. The operator should eliminate debris collected in the launder on a regular basis; otherwise, the mesh will become clogged with accumulated debris, causing the water level in the aeration tank to rise. In the worst-case scenario, this will result in tank overflow.

Where does outlet pipe take the sewage?

The sewage is routed to the settling tank/secondary clarifier via the outlet pipe.

The fine bubble diffusers are rigid pipes with long slots that are then covered with tubular synthetic rubber membranes. Through minute holes punched in the rubber membrane, the compressed air is released in the form of fine bubbles along the length of the diffusers.

In the case of fixed diffusers, compressed air is supplied via a header pipe at the tank's bottom.

Use of aeration

Aeration is a process that reduces the concentration of volatile organic compounds at the point of entry. Dissolved gases such as hydrogen sulphide, methane, and radon are also eliminated by aeration.

Although dissolved iron is oxidised by aeration, the resulting iron particles can foul the packing material in some aeration devices.

Aeration is an important step in Sewage treatment for every industry to biologically treat the sewage for further treatments.

All kinds of technology for various STP’s are provided by Netsol Water Solutions.

We are just a call away!

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.