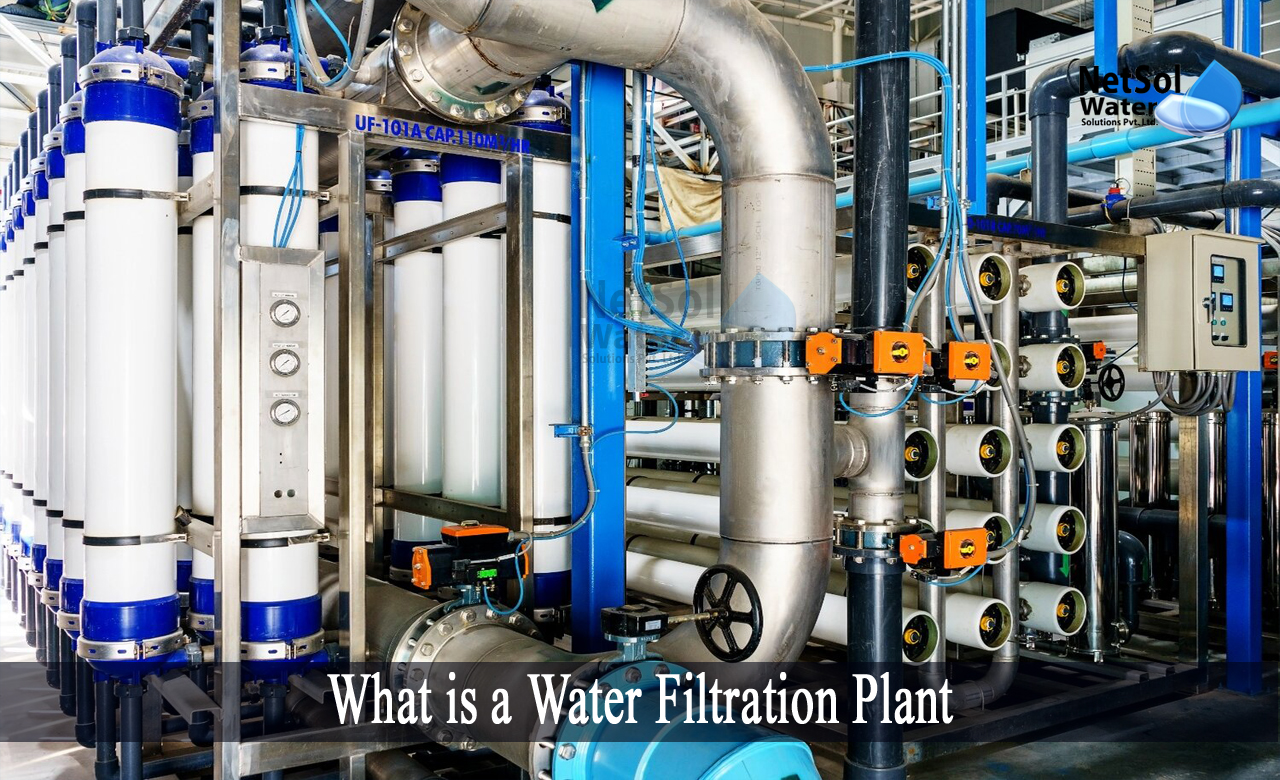

What is a Water Filtration Plant?

A water filtration plant is a facility that filters and purifies water by eliminating pollutants, dangerous contaminants, and poisonous substances. Most of these plants filter drinking water for human consumption, although other types of water can also be filtered within a water filtration plant.

The most prevalent type of water filtered at a water filtration plant is groundwater

Spring water, artesian spring water, and water recovered from wells are all examples of groundwater. Despite, the fact that this type of water is naturally filtered by various soil and rock layers, it must be further filtered before it can be consumed by people.

Lakes and reservoirs can also provide water. Lake and reservoir water, like groundwater, must be filtered to eliminate germs, protozoa, and algae. Furthermore, many lake and reservoir waters have low pH levels, which must be corrected before they can be deemed drinking water.

Some water filtration systems treat water from rivers, canals, and low-lying reservoirs. Water from these sources contains a high concentration of bacteria, algae, and other dissolved components.

Processes included in the water filtration plant

The WFP is intended to eliminate this undesired material and create water that is fit for human consumption. The raw water is pumped into a pit chamber or channel, where two chemicals are introduced and the combination is stirred by a propeller-style 'Flash Mixer.'

Raw water contains the following chemicals:

• Alum (aluminium sulphate) helps flocculate (join together) the microscopic particles suspended in water;

• Polymer, which is made up of long chain molecules that combines the 'floc' to form larger particles;

• Soda ash (sodium carbonate) to keep the water from turning acidic and so corrosive, as alum alone would. This is used at the conclusion of the process to regulate the pH.

• Near the raw water pumps is a powdered activated carbon (PAC) dosing plant (only dosed when there is an algae problem or taste or odour issue).

Working mechanism of Water Filtration Plants

To absorb odours and harmful substances produced by algae, PAC can be injected into the water. The standard procedure is then used to eliminate it. The water-chemical mixture is violently agitated a second time before being channelled, into one of the three flocculation tanks.

Large horizontal paddles revolve gently to facilitate floc formation and growth. Water enters the sedimentation tanks from the flocculation tanks. The large particles drop to the floor as the water gently travels down these tanks.

What happens in the tanks?

A sludge rake scrapes down the bottom of each of the three sedimentation tanks, collecting and pushing settled sludge towards hoppers at one end. It is then periodically released into the sludge lagoons, which are drained so that the sludge can be dried and eliminated.

The water is then run through sand filters, which catch smaller particles after the heavy floc has settled. The filters are backwashed on a regular basis by forcing a mixture of air and water up through the layers of sand, eliminating fine particles caught by the filters that could clog them.

The filtered water is collected in underground reinforced concrete clear water tanks, one of which is placed beneath the main building. As it enters these storage tanks, it is treated with chlorine to destroy any hazardous organisms and fluoride, to aid with the community's oral health.

The water is piped from the underground tanks into the town's water supply system. Reservoirs positioned at high locations in the system store water, and balance usage against pump capacity. When the pumps are turned off, the system maintains pressure by drawing from the reservoirs.

Control and Monitoring system

The filtration plant includes a sophisticated control and monitoring system that allows the equipment, to be operated manually or automatically from a central control area. The original electrical control system is now supplemented with a telemetry system.

It displays the status of all plant equipment, reservoirs, and pumping stations on a computer screen. It also enables the plant to be managed remotely using a portable computer. Alarms are registered at the plant and relayed to operators by pager outside of working hours, allowing problems to be addressed quickly.

Choose the best water treatment plant manufacturers in India

Netsol Water provides a wide range of modern solutions, including water filtration plants, water softeners, wastewater treatment plants, sewage treatment plants, and much more. We also educate our clients on how to avoid pollution by taking a sustainable strategy, and utilizing advanced treatment methods.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.