What is a plate heat exchanger?

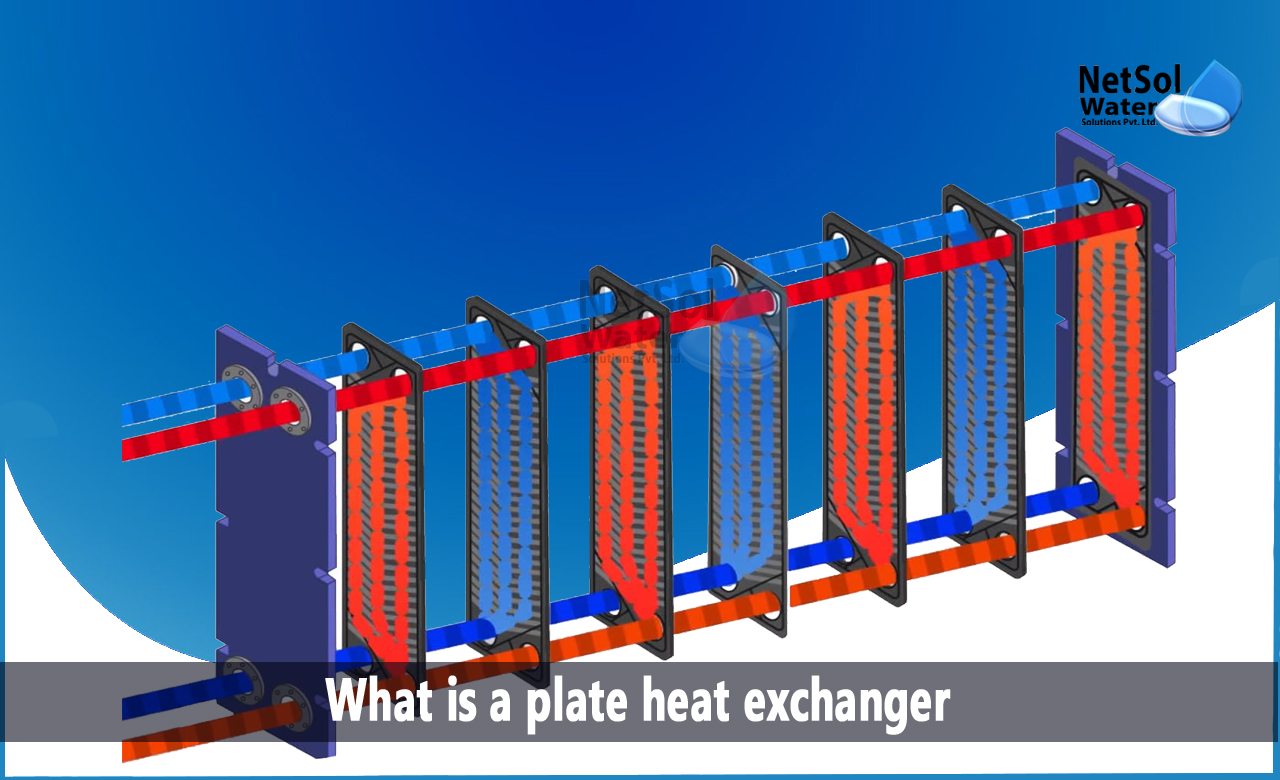

A plate heat exchanger is a type of heat exchanger that uses metal plates, to transfer heat between two fluids. The fluids are exposed to a significantly bigger surface area, than they would be in a typical heat exchanger, because they are dispersed throughout the plates.

These quicken the flow of heat and quicken the rate of temperature change. Millions of combination boilers now use plate heat exchangers, and tiny brazed equivalents can be found in the hot-water sections of these boilers.

The objective of plate heat exchanger

The plate heat exchanger (PHE) is a specialized design that can transfer heat between medium- and low-pressure fluids. Welded, semi-welded, and brazed heat exchangers are used, for high-pressure fluid heat exchange or where a more compact product is required.

Instead of a pipe passing through a chamber, two alternating chambers, usually thin in depth, are separated at their largest surface by a corrugated metal plate. The plates used in a plate and frame heat exchanger are made by pressing metal plates together, in one piece. Because, of its high temperature resistance, strength, and corrosion resistance, stainless steel is a popular metal for plates.

Components of a Plate Heat Exchanger (PHE)

Plate heat exchangers have few moving parts. Plate heat exchangers require inlets and outlets where flowing mediums (or fluids), can enter and exit the heat exchanger because they are used to transfer heat. A fluid can be either a liquid or a gas.

Gaskets and plates are used to keep the flowing mediums separate and from mixing; gaskets are adhered to only one side of each plate. The plates are hung from a carry bar and pressed together with clamping bolts. When the plates are compressed together, they form a 'plate stack.' When the plate stack is opened and closed, a guide bar ensures that the plates are properly aligned.

The two covers at opposite ends of the plate stack are the final components of interest. One cover can be moved, while the other cannot. The movable cover and fixed cover are also known as the frame plate and pressure plate. It should be noted that the inlets and outlets are only attached to the fixed cover.

Advantages of plate heat exchanger

- Improved temperature approach, true counter-current flow, and 80-90% less hold-up volume.

- Low cost - low capital investment, installation costs, and minimal maintenance and operating expenses.

- Maximum dependability - less fouling, stress, wear, and corrosion.

- Accountable - minimal energy consumption for maximum process effect, reduced cleaning.

- Simple capacity expansion - adjustable plates on existing frames.

Considerations for Design

Plate heat exchangers must be designed to withstand the process conditions in which they operate, which may include corrosive and erosive environments, due to their wide range of applications.

Plate heat exchangers can be made of a variety of materials, including metals, alloys, and plastics. Different materials make the plate heat exchanger more appropriate for various applications. If a specific flowing medium reacts aggressively when it comes into contact with certain metals, polymer-based materials such as Teflon may be used instead.

How can we assist?

If you have any questions about wastewater treatment plants, or if you would like to discuss about plate heat exchangers, please contact the Netsol Water team right away. Our team is an expert in water treatment and can help you tailor a solution to your specific requirements.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.