What Emergency Protocols Exist for ETP Chemical Spills or Leaks?

Before industrial wastewater gets discharged into the environment, Effluent Treatment Plants help to treat it. Although plants use a range of chemicals, some of these can be harmful if allowed to leak by accident. A spill or leak from chemicals inside an ETP is very harmful to living systems, the environment and the equipment itself. Certain emergency protocols for ETP chemical spills or leaks are therefore required. They play a role in preventing too much harm and ensure response teams can do their work safely and in a short amount of time.

Why Are Emergency Protocols Necessary?

ETPs deal with several hazardous chemicals such as acids, alkalis, and disinfectants. In case these chemicals leak or spill, they can:

· Cause injury to workers and surrounding individuals.

· Contaminate water bodies and land.

· Cause fire or explosion risks.

· Disrupt the treatment process.

Considering these dangers, it is essential that ETP operators maintain clear and tried emergency procedures. Adherence to emergency protocols for ETP chemical spills or leaks prevents minor problems from becoming major catastrophes.

Primary Emergency Procedures in the Event of Chemical Spills or Leaks

Below are the standard procedures applied during a chemical spill or leak in an Effluent Treatment Plant:

Alert and Notify

Plant personnel should inform the emergency response team as soon as a spill is noticed. Alarms must be sounded to alert other workers. Effective communication quickly alerts everyone about the hazard and allows them to take action.

Evacuation and Personal Safety

If the spill is significant or dangerous, people need to leave the area immediately. Anyone in the building needs to use emergency exits and find a safe place. You are required to use protective gloves, masks and suits anytime you handle chemicals.

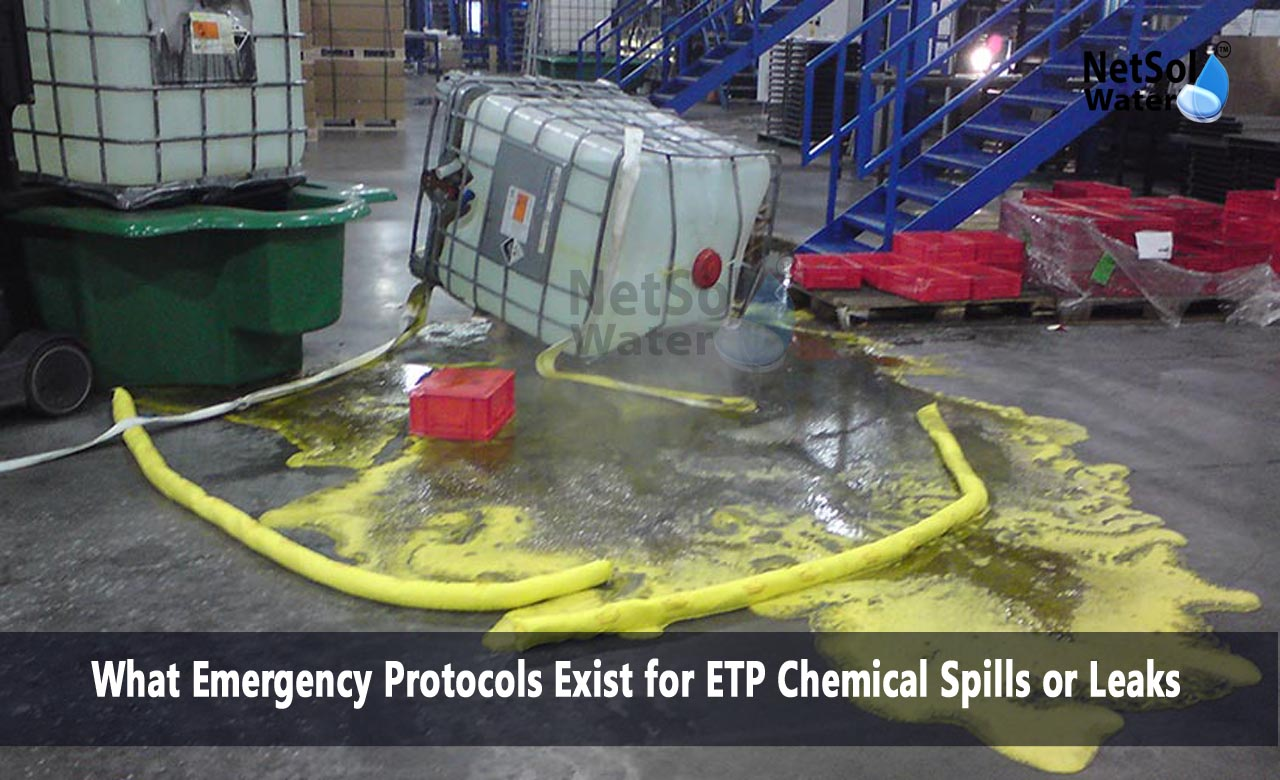

Containment and Isolation

To avoid the propagation of toxic materials, the spill has to be contained. Absorbent pads, sandbags, or spill kits may be used for this purpose. The valves and drainage outlets should also be shut down to prevent the chemicals from entering natural water bodies or ground.

Strict adherence to emergency protocols for ETP chemical spills or leaks guarantees that the containment measures are prompt and effective. This minimizes the overall effect of the spill.

Safe Cleanup and Disposal

Once contained, cleanup should be started by trained personnel. Spilled material should be removed safely and disposed of in accordance with the laws of the environment. Chemicals may have to be neutralized, accumulated, and put away in safe containers for disposal.

Reporting and Communication

The incident needs to be reported to plant management and, if necessary, to the government authorities. A report should contain:

The reason for the leak or spill

· Chemicals involved

· How it was managed

· Environmental or health impacts

These incident reports are vital for regulatory compliance and future knowledge acquisition.

Review and Training

A post-emergency review meeting should be conducted to see what went wrong. This determines any gaps in the response plan. Staff training should also be refreshed, and frequent mock exercises must be conducted to rehearse the procedures in real-life situations.

Training courses usually incorporate classes on how to respond to emergency procedures for ETP chemical spills or leaks so that all staff are well aware of what to do in the event of an actual emergency.

The Importance of Such Protocols

Without adequate emergency measures, chemical leaks can become very dangerous. Properly designedemergency protocols for ETP chemical spills or leaksassist in:

· Decreasing danger to workers

· Avoiding pollution of the environment

· Ensuring smooth plant operations

· Compliance with legal and safety requirements

· Image protection of the company

In addition, these procedures instill safety culture in the workplace. Employees feel more vigilant, ready, and accountable when there are definite procedures in place.

Conclusion

Emergency protocols for ETP chemical spills or leaks are essential to facilitate prompt and safe response when hazardous chemicals are released. From detection and alertness through containment, cleanup, and reporting, each stage aids in minimizing damage and safeguarding lives. It's not merely rule-following—it's creating a safe and responsible workplace. All ETPs need to concentrate on frequent training, appropriate equipment, and ongoing review of its emergency plans in order to remain prepared for any such occurrence.

Do you need an advice or assistance on selecting the best water and waste water treatment unit? We have solutions for all your problems!

Let us know your problem, our experts will make sure that it goes away.

For an assistance or related query,

Call on +91-9650608473 Or write us at enquiry@netsolwater.com