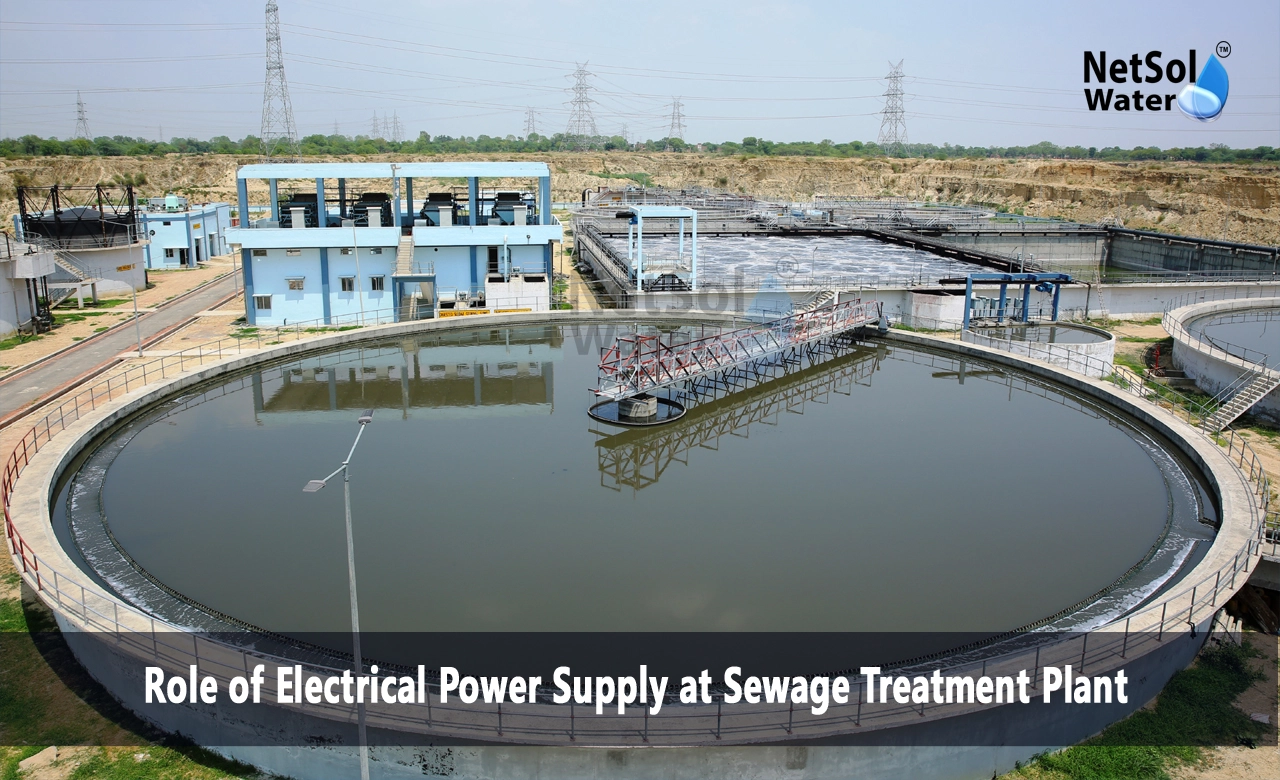

Role of Electrical Power Supply at Sewage Treatment Plant

Sewage treatment plants are essential public infrastructure that process wastewater to protect public health and the environment. However, these facilities require a reliable supply of electrical power to operate their energy-intensive processes like aeration, pumping, and solids handling. Power disruptions, whether planned or unplanned, can severely impact treatment operations and potentially lead to the discharge of untreated or partially treated sewage. This blog examines the critical role of electrical power supply systems at sewage treatment works and strategies to ensure uninterrupted operations.

Energy Demands of Sewage Treatment

Wastewater treatment is an extremely power-hungry process across all stages, from collection to discharge. The largest consumers are the aeration systems that supply oxygen for biological treatment, followed by pumping requirements for influent, effluent and recycling streams. Other major loads include processing equipment like sludge thickeners, dewatering systems, disinfection units and odour control systems. Overall, sewage plants can account for up to 30% of a municipality's electrical energy usage, making them vulnerable to power shortages or failures.

Onsite Power Generation

Given their critical nature, most large treatment plants include onsite power generation capabilities to maintain operations during grid outages. Diesel generator sets offer a reliable backup source with enough fuel storage to run for extended durations. However, emissions concerns have led many plants to transition to cleaner alternatives like biogas from anaerobic digesters, natural gas turbines and even solar photovoltaics for supplemental power. Properly sized and configured with automated switching, these distributed energy systems ensure seamless supply handover if utility power is interrupted.

Dual Power Feeds

Another redundancy measure employed for reliable power supply is installing separate electrical feeds from two independent utility substations or grids. This dual feed topology creates redundancy by allowing service from an alternate source if one feed is disrupted due to external factors like weather or grid failure. Critical sewage treatment processes remain energised while the fault is isolated and repaired by simply transferring over to the second feed.

Prioritised Load Management

During extended outages when backup generators have limited runtimes, prioritising which processes get powered first becomes crucial. Modern plants use intelligent power management systems to shed non-critical loads while ensuring key treatment operations like disinfection and aeration are prioritised based on programmable settings. This prevents complete process shutdown and bypassing of untreated sewage. Manual load-shedding approaches are also used when automated options are unavailable.

Power Monitoring and Efficiency

Besides supply redundancy, monitoring electrical usage helps optimise energy efficiency and reduce overall power demands. By analysing energy consumption across processes, ageingequipment can be replaced with more efficient models and operational changes made to reduce wasteful usage. Power factor correction systems and load balancing across backup generators further enhance the utilisation of available electrical infrastructure during outages.

Emerging Technologies

As renewable power sources become cheaper and storage technologies advance, sewage plants are evaluating innovative electrical system designs. These include carbon-neutral microgrids with solar, wind and biogas sources feeding back into the grid. Emerging solid-state battery storage replaces traditional lead-acid cells for backup power, while smart grids allow two-way power flows and load balancing between treatment plants. Such modern approaches enhance energy security while also reducing environmental impacts.

Conclusion

A reliable electrical power supply is absolutely vital for ensuring continuous operations at sewage treatment plants, which protecting public health and environmental integrity. Having adequate backup power provisioning, redundant utility feeds, load prioritisation systems and enhancing energy efficiency are all established practices. However, more sustainable and self-sufficient electrical systems utilising renewable distributed generation and storage offer a promising future as the water industry moves towards a smaller energy footprint and greater resilience against power disruptions.

To explore customised Commercial RO plants, Industrial RO plants, ETP or STP solutions for your needs in your areas and nearby regions, contact Netsol Water at:

Phone: +91-965-060-8473, Email: enquiry@netsolwater.com