How is wastewater treated in the ice cream industry?

An industrial ice cream production business needs a solution for treating wastewater created during the manufacturing of ice cream in order to comply with sewage network discharge regulations.The effluent from the ice cream industry is largely made up of organic matter and suspended solids from the raw materials used to make ice cream: cow's milk and fruit, both of which are high in fat and protein.

The development of the best strategies for minimising pollution, optimising natural resource utilisation, and increasing energy efficiency is one of the ice cream company's environmental commitments. In reality, an industrial ice cream shop can generate a lot of waste water, which means there will be a lot of clean-up to undertake before the water is dumped into the public sewer system. As a result, one of their top priorities in terms of corporate social responsibility is purifying the wastewater utilised in their production operations, which has been our task as experts in the design of industrial water clarity systems.

Waste Water Treatment

The chemical prescription is fairly straightforward in most industrial pre-treatment applications where solids removal is the primary goal to coagulate solids with a metal salt, neutralise pH with acid or caustic soda, and then agglomerate solids into larger chunks using a polymer flocculant so they float or sink. The sediments are then removed from the water using a dissolved air flotation (DAF) device.

In any effluent stream, the performance of the traditional chemical technique is heavily dependent on flow rate and composition consistency, but this is especially true in dairy applications. The EQ tank is designed to store 4 to 8 hours of flow, capturing and mixing it to bring the wastewater composition back to normal. This enables the treatment equipment to be tuned to a fairly consistent pollutant load at a constant flow rate. Using a large EQ tank with dairy effluents, on the other hand, becomes troublesome since milk products deteriorate quickly and emit bad aromas. Of course, odour control techniques (such as underground tanks, tank covers, and air scrubbers) can be adopted, but they come at a high expense in terms of both capital and operating expenditures.

The odour is one issue, but the volatility of the dairy wastewater, which is held for hours at a time, becomes even more difficult to manage. Various bacteria in milk change the chemical environment throughout time and as the temperature changes. Sugars are converted to lactic acid, proteins are transformed to ammonia, and pH levels rise and fall as a result of this process.The complex nature of milk in dairy plant effluents makes determining the optimum chemical dosage rates a changing target, which is both difficult and costly from an operations standpoint.

Furthermore, it creates a bit of a guessing game when it comes to the final water quality. When huge fines and plant closures are on the horizon, this is a difficult situation to be in.

On the backside of the DAF system, the rate at which dairy products fermented in the wastewater treatment process is also problematic. Skimmed sludge degrades even faster in its semi-solid form than liquid wastewater, resulting in foul aromas and a stinking solid mass of worthless material. Because metal salts were used in the coagulation process, the float sludge is unsuited for rendering or any other practical application. Sludge is treated as a secondary waste material.

Netsol’s helping hand in treating waste water in ice cream industries

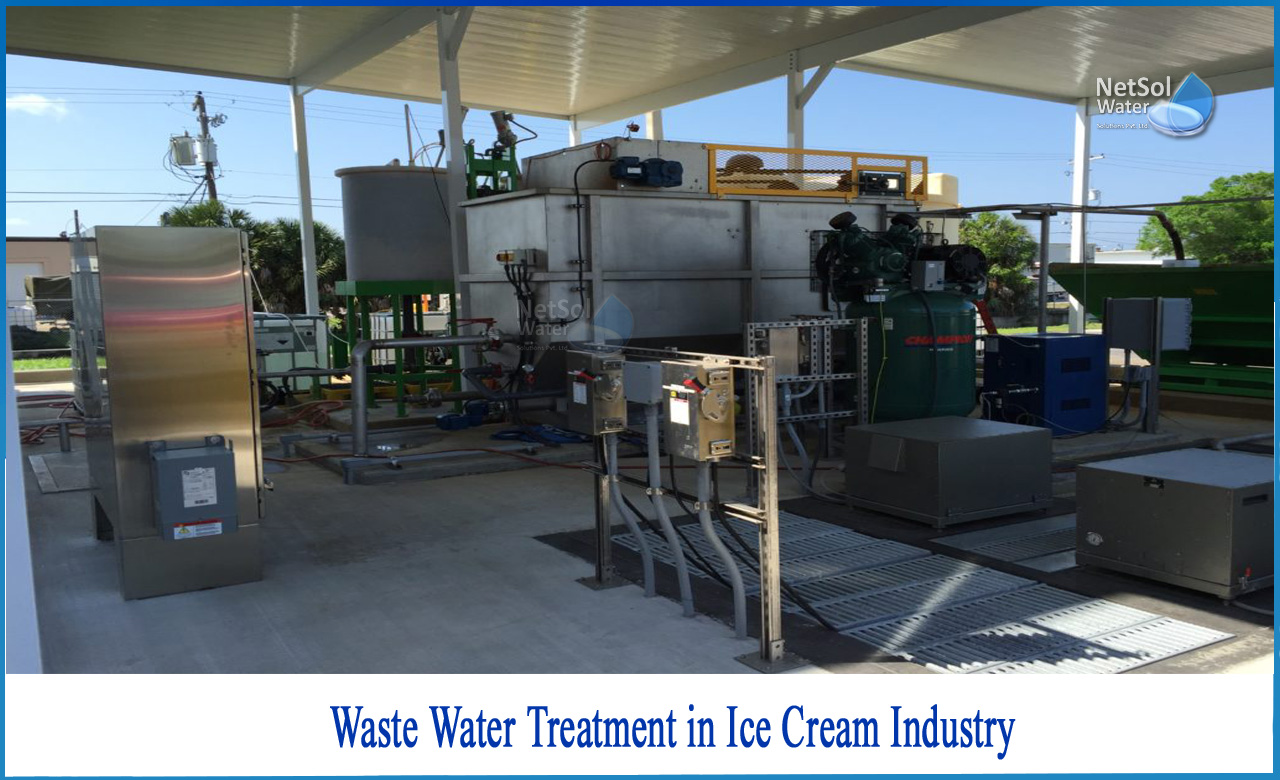

An equalisation tank, continuous extraction of free floating fats, chemical reaction tanks, a dissolved air flotation (DAF) system, and sludge dewatering are all part of Netsol's state-of-the-art physical/chemical treatment system.

Netsol Water will design and build the full system to handle the client's wastewater system permitting process.

The following are the outcomes:

• The plant's FOG levels can be lowered by an average of 50%.

• The amount of total suspended solids (TSS) in the water can be reduced by nearly 99 percent.

• The biochemical oxygen demand (BOD) can be lowered by nearly half.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.