What do you mean by Primary treatment of Sewage treatment plant?

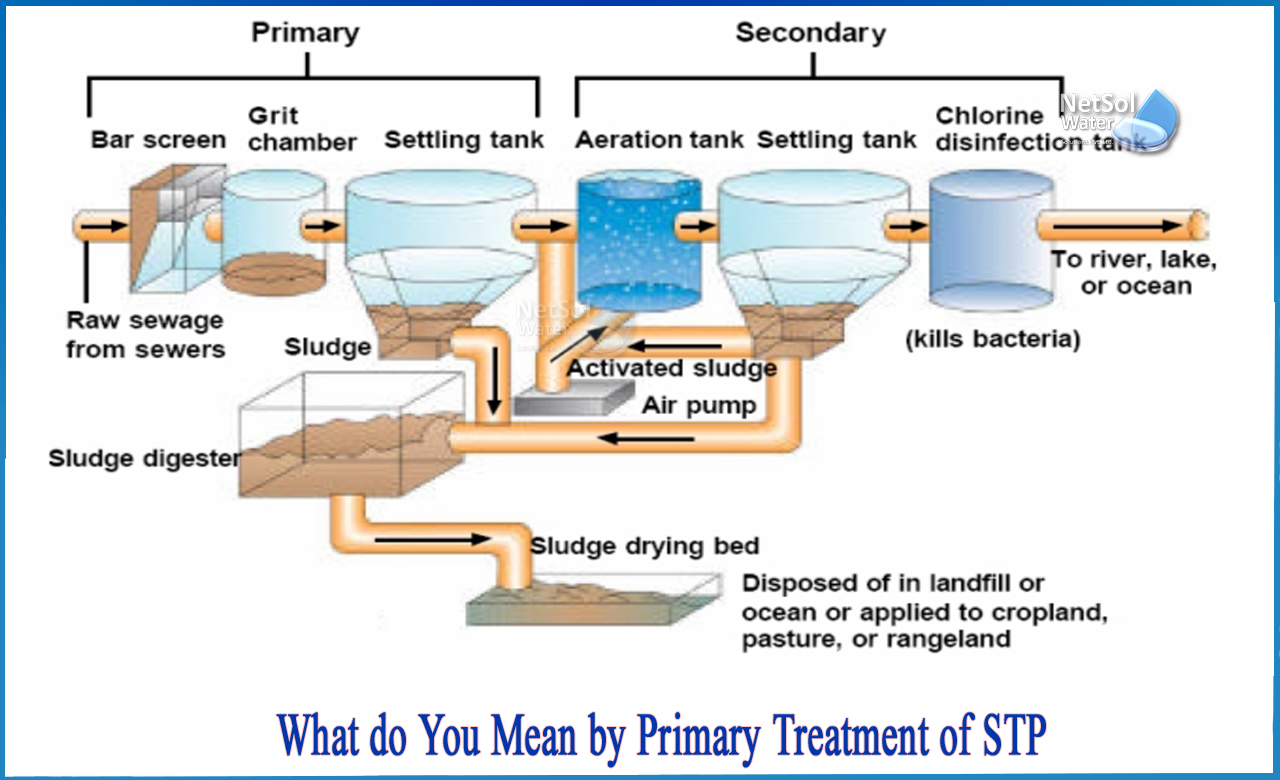

The Preliminary Treatment Wastewater treatment is a simple sedimentation procedure that removes suspended organic particles from sewage. To remove finely split and colloidal particles, chemicals are occasionally utilised.

Primary Treatment objectives:

The fundamental goals of wastewater treatment are as follows:

1. To lessen the strength of sewage by 30 to 50 percent.

2. To reduce the amount of settleable solids by 80 to 90 percent.

3. To lower BOD by 30 to 35 percent.

4. To prepare the sewage for subsequent treatment.

Primary sedimentation tank:

The primary sedimentation tank, also known as the clarification tank, is positioned immediately after the grit chamber. It can take the form of a rectangle, a circle, or a square. The basic idea and construction details are the same as for a standard sedimentation tank.

Primary Sedimentation Tank Varieties:

1. Standard main sedimentation tank

2. Circular Radial Flow Tank

3. Up-Flow Tanks

Primary Sedimentation Tank requirements: Design of Primary Sedimentation Tank:

The following steps are included in the design of primary treatment wastewater:

1. Hydraulic loading rate (overflow rate)/settling velocity

Vs = (0.3 – 0.7) mm/sec (1 – 2.5 m/hr)

2. Detention time/retention period

Td = 1–2 hours

3. Tank depth = (1–5) m

4. Percentage of BOD elimination (20 – 40%)

5. Suspended solids removal (30 – 60%)

6. The minimum number of tanks is two

7. Accumulated sludge = 2.5 kg of wet solids per m3 of flow.

Working of Primary Treatment:

The primary treatment eliminates particles that will either float or settle out naturally by gravity. Screening, grit removal, and sedimentation are all physical processes.

Screens are comprised of long, narrow metal bars that are tightly separated. They prevent floating waste like wood, rags, and other bulky things from clogging pipelines or pumps. In contemporary facilities, the screens are cleaned automatically, and the waste is disposed of immediately by burying on the plant grounds.

A comminutor may grind and shred material that goes through the screens.

Later, sedimentation or flotation operations remove the shredded particles.

Grit chambers are deep, narrow tanks constructed to restrict the flow of water so that particles like sand, coffee grinds, and eggshells settle out. Pumps and other industrial equipment suffer from increased wear and tear as a result of grit. Its removal is especially critical in places with combined sewer systems, which transport a significant amount of silt, sand, and gravel washed off roadways or land during a storm.

Sedimentation tanks extract suspended particles from sewage that have passed through filters and grit chambers. These tanks, also known as primary clarifiers, give about two hours of detention time for gravity settling to occur. The sediments eventually settle to the bottom as the sewage gently runs through them.Mechanical scrapers carry the settled solids, known as raw or primary sludge, down the tank bottom. Sludge is collected in a hopper and pumped out for disposal. Surface-skimming mechanical devices remove oil and other floating contaminants.

Conclusion

NETSOL WATER is India's leading manufacturer of water treatment and sewage treatment systems. We are the leading service provider for waste and waste water solutions, including remedies, testing and monitoring, analysis, and recommended corrective steps, based on our many years of expertise.

We are the premier supplier of solutions for treating sludge and industrial wastewater in order to protect water and the environment.