Worldwide, wastewater treatment facilities are utilized to handle the enormous volume of wastewater produced each day. The protection of the general public from health risks brought on by untreated wastewater, is the fundamental objective of every wastewater treatment plant manufacturer.

In addition, wastewater treatment is necessary to stop pollution of the environment. The most crucial step in any treatment plant where living microorganisms are crucial, to the breakdown of organic waste is biological wastewater treatment. For the greatest treatment outcomes, the operational control parameter for MLSS among the system's many components needs to be evaluated.

What is MLSS?

The overall concentration of solids in an aeration tank is measured by Mixed Liquor Suspended Solids, or MLSS, in the wastewater treatment process. It consists of suspended non-biodegradable material, organic substances, and bacteria.

Additionally, MLSS is regarded as a combination of suspended particles and influent wastewater, which serves as a gauge of the system's biomass or biology.

Optimization of MLSS in Wastewater Treatment

The MLSS concentration used in conventional activated sludge wastewater treatment plants, ranges roughly from 1500 mg/l to 5000 mg/l. It has been noted that a higher MLSS concentration is known to offer both benefits and drawbacks.

For smaller aeration tanks where the treatment level is constant, it is advantageous. But occasionally, as MLSS concentration rises, aeration effectiveness can fall.

Factors determining higher MLSS

Increased BOD loading, thickening sludge, high flow rates, insufficient settling times, and nutritional shortage in the biomass, are all signs of higher MLSS.

Factors determining lower MLSS

Low MLSS indicates that the DO concentration is not being maintained, fewer organisms are surviving, the flow rate is decreasing because fewer microorganisms are present, and both stalked and free-swimming ciliates are declining.

This means that for wastewater treatment plants to operate at their best, an ideal amount of MLSS concentration must be maintained. Understanding the bacterial activity in the system would help in achieving it.

What are the steps for MLSS Evaluation in Wastewater Treatment?

1: The first step entails gathering an MLSS grab sample and passing it through the filter.

2: Second, the filter should be ignited for roughly 15 to 20 minutes in a muffle furnace (550 degrees). This is done to dry the residue.

3: After the filter has cooled, the residue should be moved to a desiccator for cooling in the third stage.

4: Finally, weigh the filter residue that is still there.

After that, you may use the following formula to determine how many volatile solids are present in the sample:

VSS, in (mg/l) =Weight of Material Lost by burning in (g)/ sample volume in (ml)

It helps with return activated sludge (RAS) flow optimization for a constant load, during influent flow and load-variation periods. However, since online instrumentation is expensive and necessitates on-going calibration, manual assessment using a sample is still thought to be preferable.

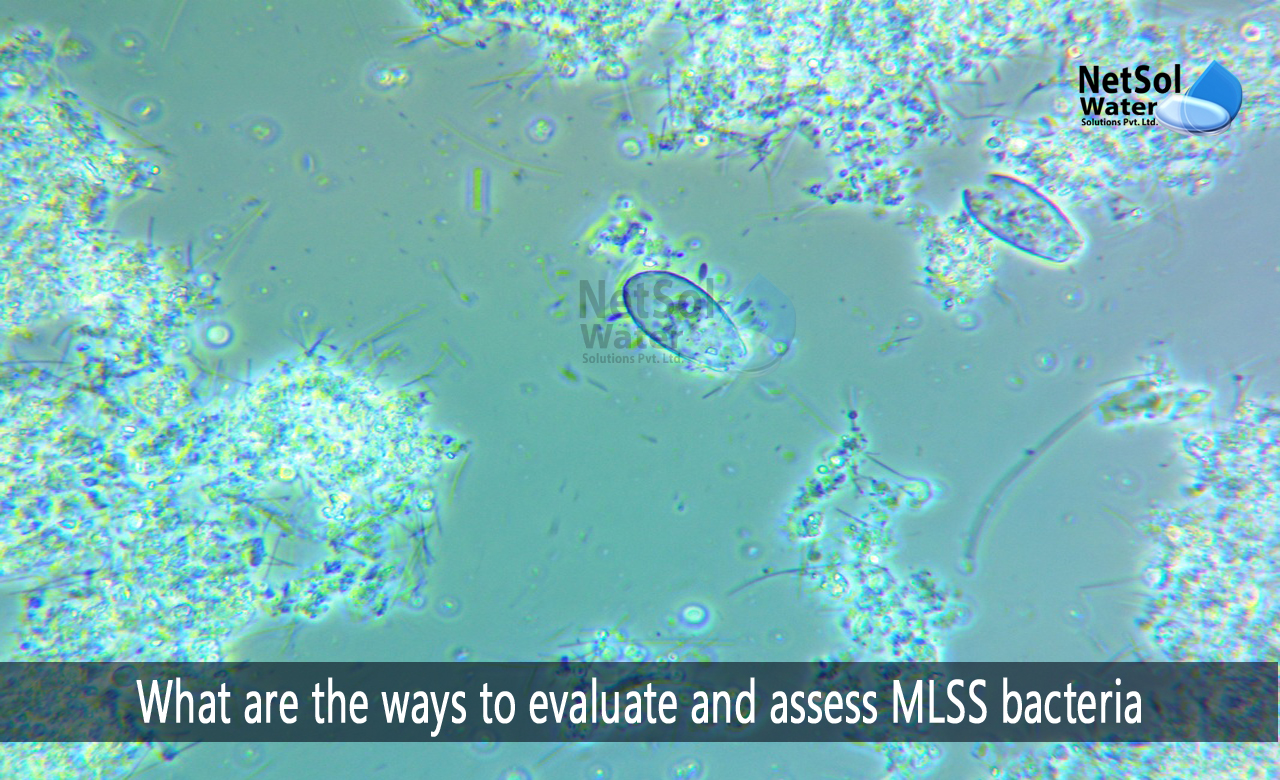

What are the ways to evaluate and assess MLSS bacteria?

Several techniques have been created during the past few decades to analyse and evaluate MLSS, in wastewater treatment. It consists of manual collection and laboratory analysis, intended to increase the effectiveness of wastewater treatment by biological means.Some of them are:

· Rate of Oxygen uptake

The rate at which oxygen is ingested by the biomass is known as the oxygen uptake rate. It aids in the measurement of microbial activity.

When rate of oxygen uptake is lower than usual, MLSS is being harmed by toxins. Increased levels indicate organic overloads. Another possibility that can take place is the rapid return of high intake to normal. It demonstrates that the low MLSS concentration is caused by an improper food to microbe ratio.

· Test of Settleability

The density and how it settles in a clarifier affect biomass efficiency. As a result, a Settleometer is used to conduct a Settleability test. Operators can determine the sludge's age by logging the biomass's Settled Sludge Volume (SVV).

Solids that settle more quickly might be older muck, while those that settle too slowly might be rinsed away, by heavy hydraulic loads.

· ATP analysis and plate counts

In the Plate Counts method, tests are done in laboratories utilizing plate count media to examine tiny amounts of MLSS. It aids in figuring out the wastewater's microbiological population.

A luminometer, which emits light during ATP reactions, is used in ATP analysis to examine the ATP, which microorganisms store as energy.

· Cytometry in Flow

It involves using fluorescent dyes to assess each bacterial cell's viability, in an effluent sample.

· Molecular Analysis

It enables the measurement of the DNA of particular higher life forms of bacteria, such as nitrifiers and nocardia, as well as MLSS bacteria. This testing has the benefit of being both quick and extremely accurate.

Analysis of Bacteriological Wastewater

By examining the microbial population and the current issues, the study can help you comprehend the current state of the biological system of the wastewater treatment facility. It will also assist you in taking sensible actions to increase the system's effectiveness.

Study on Wastewater Treatability

Depending on the type of industrial wastewater treatment plant, Netsol Water will assist you in choosing the appropriate microbial population, for your biological system by proving its appropriateness and sustainability.

Get your wastewater treatment plants designed, manufactured and installed by Netsol Water Solutions!

One of the top businesses offering successful and effective solutions, for wastewater treatment issues is Netsol Water. Our products and wastewater treatment equipment’s can speed up every procedure, and improve the efficiency of the treatment facilities. Through its biological solutions, it also aids in the optimization of MLSS in wastewater treatment, and raises the effectiveness of the biological treatment process in wastewater treatment plants.

Our advanced treatment products aid in the treatment of wastewater, reducing organics, inorganics, FOGs, TDS levels, heavy metals and other microscopic organisms, with the elimination of unpleasant odours.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.