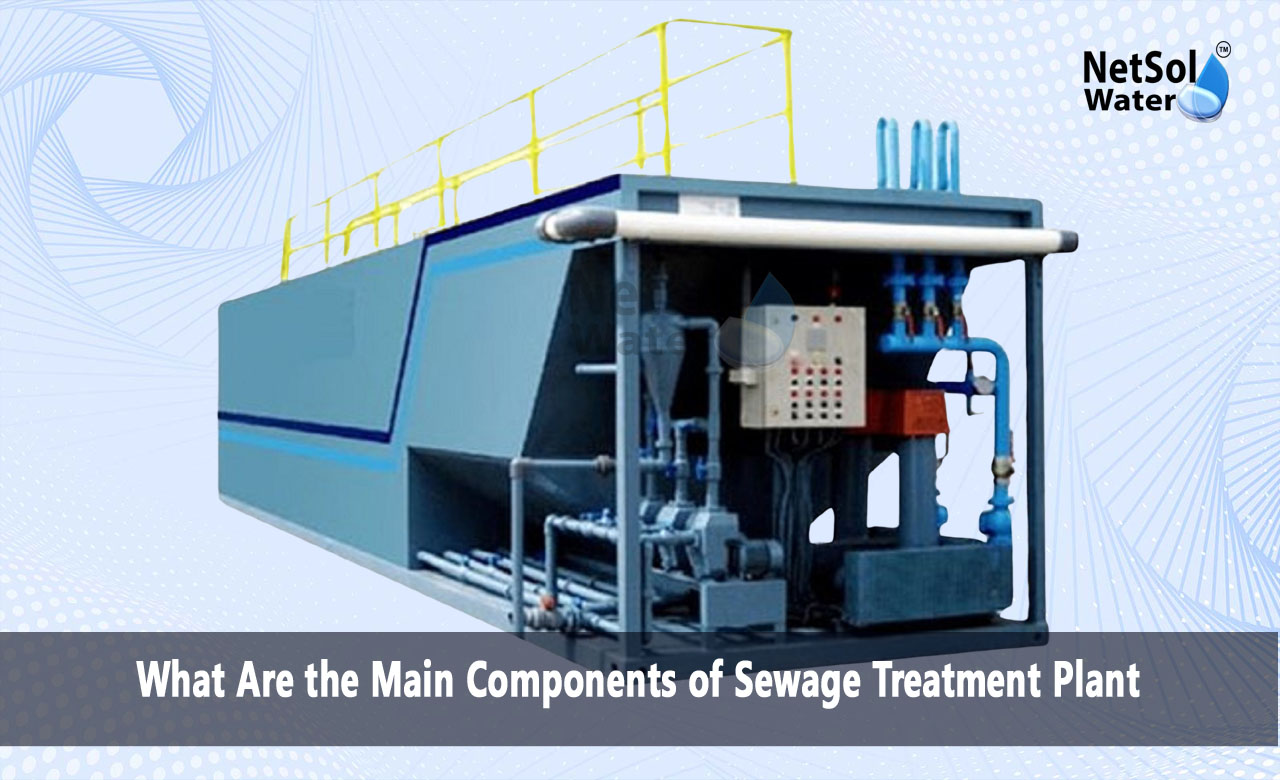

What Are the Main Components of STP Plant?

Sewage Treatment Plants are necessary to purify domestic wastewater, industrial wastewater, and commercial wastewater. STPs treat the sewage to preserve the environment and return the treated sewage to water bodies or use it in a hygienic manner. To have a knowledge of how it functions, one should be well versed with the main components of Sewage Treatment Plant that is, the key operations of screening, aeration, and clarification. All of these elements combined deliver effective impurity removal from sewage.

We will discuss these primary components in easy terms, describing their purpose and significance in the entire sewage treatment process.

Knowing the Main Components of STP

An STP is made up of several components and units, all of which have been made to play certain roles in the sewage treatment. Among them, screening, aeration, and clarifiers are fundamental ones. They all process, treat, and purify the wastewater in phases.

Screening

Screening is the first step in all Sewage treatment plants. It is the removal of coarse solids and debris that come with raw sewage to the plant. The solids in this group are objects such as plastics, rags, leaves, sticks, and other unwanted substance that can clog or destroy equipment downstream.

Screens are just metal grill or mesh barriers of opening widths to let water and small particles pass through but prevent larger stuff from getting through. Screening is what keeps pumps, pipes, and other equipment free from clogging and destruction.

Screens are typically hand washed in most operations, and in better systems, mechanical scrapers or conveyors remove build-up debris continuously. Proper screening is important because it avoids operation issues and enables more efficient processing in subsequent stages.

Aeration

Aeration is the primary process of the biological treatment of an STP. It is used to deliver oxygen to naturally occurring microorganisms present in sewage as well as to offer a platform for decomposition for the organic pollutants.

When aerated, air is supplied to the sewage through diffusers or mechanical aerators and forms bubbles that dissolve oxygen in water. The oxygen serves a critical purpose in allowing bacteria and other microorganisms to survive and degrade organic waste with ease into simpler compounds such as carbon dioxide and water.

Aeration not only enhances the breakdown of the pollutants but also acts to arrest the stink of the sewage. This bioactivity tremendously minimizes the biochemical oxygen demand (BOD) and chemical oxygen demand (COD) of the sewage, or in other terms, the water turns out to be much cleaner.

Effective aeration system design and performance ensure that oxygen is present in adequate amounts, and this has a direct impact on the overall efficiency of the entire STP.

Clarifiers

The sludge water consists of treated water and suspended substances after biological treatment in the aeration tank, for instance, microbials (sludge) biomass. The clarifier or sedimentation tank is the second main components of STP.

Clarifiers enable the solids to settle by gravity. When slurry is added to the clarifier, heavy particles settle to the bottom to create sludge while purer water rises on the surface. The clarified water is pumped out for additional treatment or discharge.

The settled sludge is pumped out periodically and either recycled back into the aeration tank to sustain microbial communities or passed forward for additional treatment and sludge disposal.

Clarifiers are required because solids need to be eliminated from treated water. This guarantees that the effluent quality is guaranteed prior to being released or reused.

Why These Components Are Essential Among the Major Components of STP

Screening, aeration, and clarifiers all make up the core of any Sewage treatment plant. Screening avoids system damage and clogging, aeration initiates the biological degradation of organic waste, and clarifiers filter treated water out of solids effectively.

All these components must be operated and designed with maximum care such that the STP can work in the best possible way. Any failure at any one of these levels may lower the treatment efficiency, cause equipment failure, or result in the release of poorly treated water.

Other Components Aiding STP Operation

While aeration, screening, and clarifiers are primary units, grit chambers, sludge digesters, and disinfection units are also significant. Grit chambers eliminate sand and grit to save mechanical equipment. Sludge digesters stabilize the sludge collected in order to decrease volume and odor. Disinfection units like chlorination or UV disinfection kill remaining pathogenic microorganisms prior to discharge.

Together, all these components make up an STP an effective system for safe sewage treatment.

Conclusion

Knowing what the main components of STP are—screening, aeration, and clarifiers—provides one with an idea about how sewage treatment processes work. Screening eliminates excess large wastes, aeration allows for biological decomposition of dangerous particles, and clarifiers filter out solids to create clean water.

Aptly crafted and well maintained, these parts help ensure that STPs keep our health and the environment safe by effectively treating sewage. Be it a small town or a big city, these basic parts are the backbone of each Sewage treatment plant.

Do you need an advice or assistance on selecting the best water and waste water treatment unit? We have solutions for all your problems!

Let us know your problem, our experts will make sure that it goes away.

For an assistance or related query,

Call on +91-9650608473 Or write us at enquiry@netsolwater.com