What are Sequencing Batch Reactors?

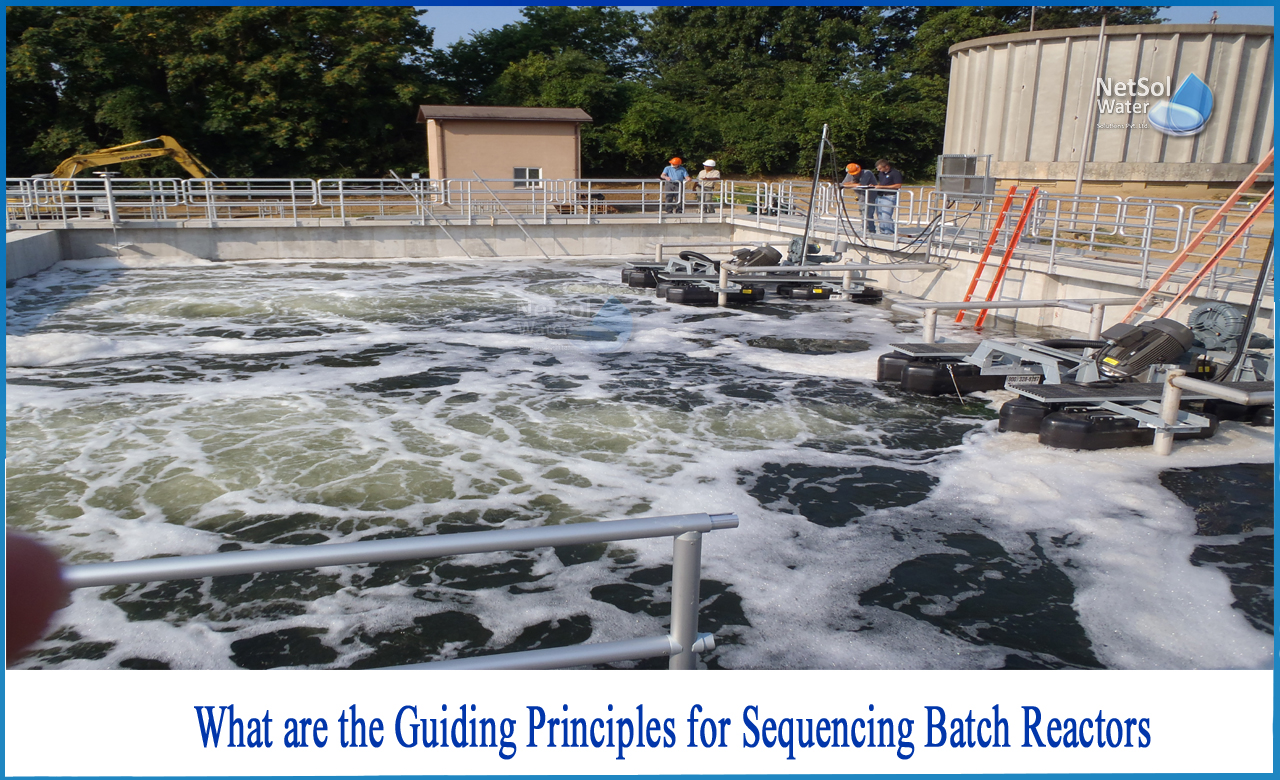

Sequencing batch reactors (SBR), also known as sequential batch reactors, are industrial wastewater treatment tanks. These reactors handle wastewater in batches, such as sewage or waste from anaerobic digesters or mechanical biological treatment plants.

It is a wastewater treatment technology that uses a fill-and-draw activated sludge technique. In this system, wastewater is pumped into a single "batch" reactor, where it is treated to eliminate contaminants before being released. Equalization, aeration, and clarifying processes take place in a single batch reactor. Two or more batch reactors are employed in a specified sequence of operations to improve the system's performance.

SBRs have been successfully used to treat both municipal and industrial wastewater. They are suited for wastewater treatment applications characterized by low or intermittent flow conditions and are designed and operated to enhance the removal of nitrogen, phosphorus, and ammonia, in addition to removing TSS and BOD.

The essential components of SBR are:

a) Reactor basin

b) Waste sludge draw-off mechanism

c) Aeration equipment

d) Effluent decanter

e) Process control system

Stages of operation in SBR Systems

Most SBRs have four or five stages of operation: fill, react, settle, draw, and idle.

The fill stage may be static, mixed, or aerated. Sludge is typically wasted in the react phase to ensure uniform effluent solids quality, but many sludge wasting options are possible to meet site specific needs. Because the SBR is a batch process, a batch-based design approach should be used.

What are the Guiding Principles for SBR?

With proper design considerations, the inherent flexibility of SBR treatment process can enable adaptation to regulatory changes for effluent parameters such as for nutrient removal. As with conventional activated sludge variants, there are several SBR variants each of which require their own design considerations. Design and operation for efficient nitrogen removal provides enhanced process stability, especially with operating temperatures greater than 20oC.

Level sensors and a timing device or microprocessor are used to regulate the system as a whole.

For essentially the same physical plant, the SBR may be run as a labor-intensive, low-energy, high sludge yielding system due to the flexibility associated with operating in time rather than space. Initial capital expenses can also be bargained off with labour, energy, and sludge yield.

The SBR's operational flexibility also allows designers to utilize it to achieve a variety of treatment goals, including one at the start (e.g. BOD and suspended solids reduction) and another subsequently (e.g. nitrification or denitrification in addition to removal of BOD and suspended solids).

What can we offer?

Netsol Water is one of India's major water and wastewater management company, specialized in the design, manufacture, and delivery of custom-made treatment systems, industrial machinery, and luxury amenities for the water industry. We can customize Sequencing Batch Reactors (SBRs) that will cater to all your needs and at the same time effectively treat different types of wastewater.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.