What are the different phases of treatment in Commercial RO Filter?

Reverse osmosis removes pollutants from unprocessed water, or feed water, when pressure forces it through a semipermeable membrane. To produce clean drinking water, water flows from the more concentrated side of the RO membrane—which has more impurities—to the less concentrated side—which has less contaminants. The permeate is the name for the produced fresh water. Waste or brine is the term for the leftover concentrated water.

Small pores in a semipermeable membrane allow for the passage of water molecules but impede the passage of pollutants. Osmosis involves the concentration of water as it moves through the membrane to achieve equilibrium on both sides. However, reverse osmosis prevents pollutants from passing through the membrane's less concentrated side.

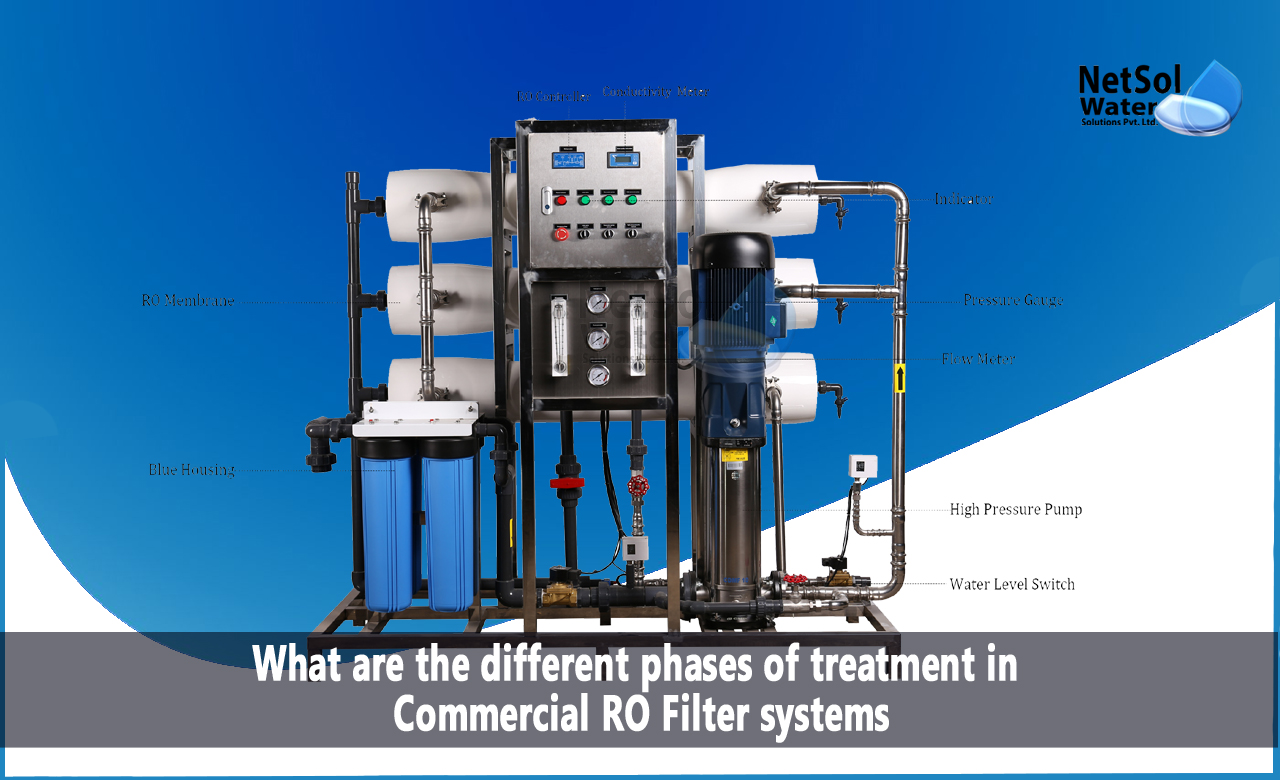

Different phases of treatment in Commercial RO Filter systems

A reverse osmosis system's main component is the RO membrane, but it also has additional filters. There are 3, 4, or 5 filtration stages in a RO system.

In addition to the RO membrane, every reverse osmosis water system also includes a sediment filter and a carbon filter. Depending on whether the filters are used before or after the membrane, the filters are referred to as prefilters or postfilters.

There are one or more of the following filters in each type of system:

1. Sediment Pre-Filter:

It eliminates debris as small as 5 microns, including dirt, corrosion, and silt. Cartridges for sediment come in a variety of designs.

Increased surface area and longer life are benefits of pleated filters. These cartridges can be cleaned and used again.

Filters made of melt-blown polypropylene are intended to filter out silt, rust, and other impurities from water. The most often used sizes for drinking water applications are 5 and 20 micron.

For commercial filtering needs, string coiled filters are a practical and affordable option. These cartridges are available in a variety of media types and are used for a variety of purposes.

2. Carbon Pre-Filter:

With a typical 0.5 to 10 micron filtration capacity, activated carbon block filters are also useful for particulate filtration, removing chlorine's taste and odour, reducing insoluble lead, and occasionally even eradicating Giardia and Cryptosporidium. A third housing is present in a five-stage reverse osmosis system to accommodate an additional carbon block cartridge.

3. Reverse Osmosis Membrane:

Membranes known a?s thin film composite membranes (TFC or TFM) are semi-permeable membranes primarily used in water filtration or desalination systems. In chemical applications like batteries and fuel cells, they are also utilized.

4. Post Carbon Filter:

Normally, the membrane housing of a reverse osmosis system is where inline post filters are attached. Any chlorine or pollutants that the other cartridges or membrane failed to catch are removed by the post filter.

Do you need an advice or assistance on selecting the best water and waste water treatment unit? We have solutions for all your problems!

Let us now your problem, our experts will make sure that it goes away.

For an assistance or related query,

Call on +91-965-060-8473

Or write us at enquiry@netsolwater.com