What is anaerobic wastewater treatment?

Anaerobic wastewater treatment is a biological method that involves microorganisms degrading organic contaminants in the absence of oxygen.In a typical anaerobic treatment cycle, wastewater enters a bioreactor receptacle.

Sludge, a thick, semi-solid substance made up of anaerobic bacteria and other microorganisms, is used to fill the bioreactor. These anaerobic bacteria, sometimes known as ‘anaerobes,’ digest the biodegradable materials in the wastewater, resulting in an effluent with decreased BOD, COD, and/or TSS, as well as biogas byproducts.

How is anaerobic treatment different from aerobic treatment?

Microorganisms are used in both treatment methods to break down organic pollutants in wastewater. The main distinction is that aerobic processes require oxygen, whereas anaerobic ones do not. Each type of treatment method is best suited for specific wastewater streams, and the waste byproducts produced by each treatment differ.

Anaerobic systems offer lower operational costs and energy requirements due to the variations in system design between the two processes, but they are slower and require more capital up front.

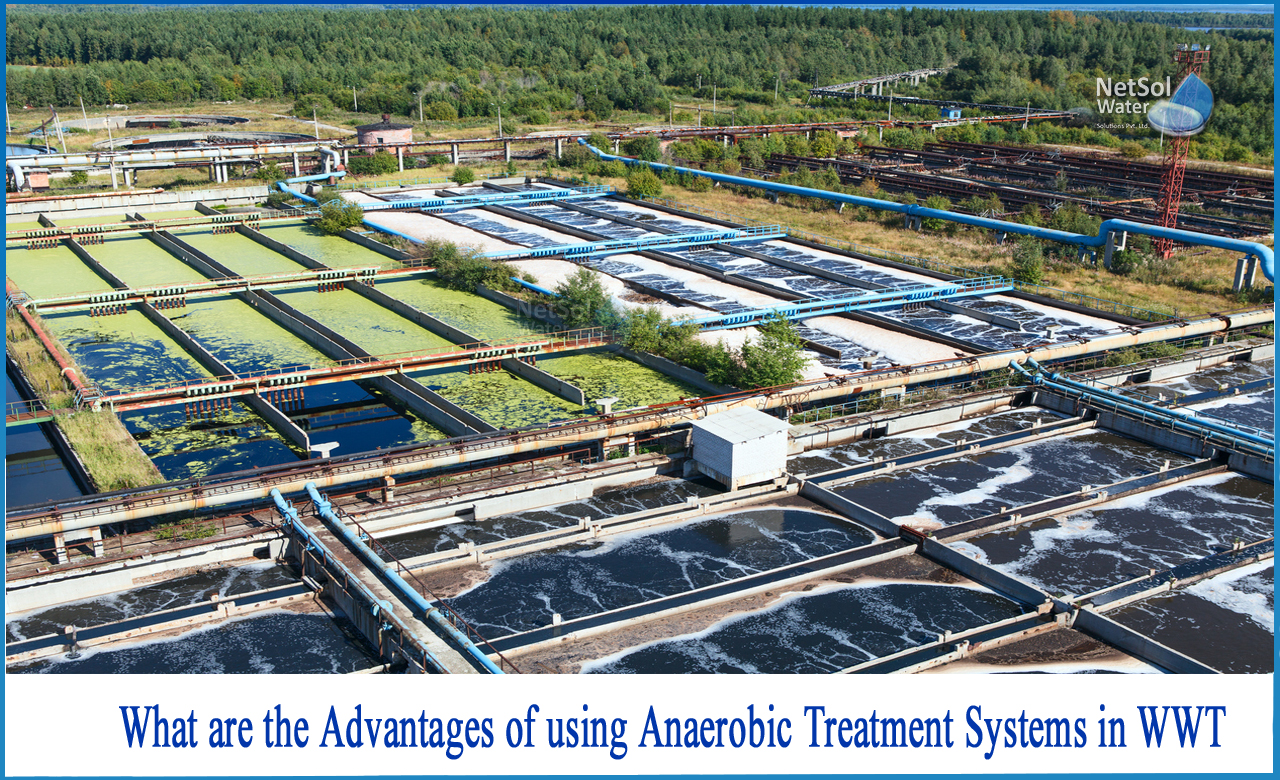

What are the advantages of using Anaerobic Treatment Systems in WWT?

Here are some of the benefits of adopting Anaerobic Digestion as the most reliable method for industrial wastewater treatment. These results are in comparison to the commonly used aerobic techniques for eliminating Organic Pollutants from wastewater streams.

1. Low energy consumption: Anaerobic treatment is, at its core, an energy-generating process that generates energy through the generation of a byproduct, namely methane-rich biogas. Because methane is used for energy generation elsewhere in the plant, more than 90% of the caloric value of the organic substrates being processed is preserved. Furthermore, mechanical mixing in current anaerobic bioreactors does not necessitate a substantial amount of energy. During aerobic treatment, however, the majority of the caloric value of the organic substrates is lost as non-recoverable heat. As a result, aeration in aerobic bioreactors necessitates a large amount of energy.

2. Small reactor surface area: For the anaerobic digestion of industrial effluents and waste water treatment, a variety of digesters are available. Anaerobic digesters, on the other hand, are known to have a small surface area and the ability to integrate tanks, mixers, covers, and heating systems into a single reactor. As a result, the area used may always be optimized and adapted to meet the needs of the business.

3. Reduced chemical use: Almost all microbes need nutrients like nitrogen, phosphorous, and sulphur to flourish. Many chemical and petrochemical wastewater streams, on the other hand, have relatively low concentrations of these nutrients. Additional nutrients must be dosed into the wastewater if nutrient concentrations are insufficient; however, because the amount of biomass formed is directly proportional to the amount of biomass formed, the chemical loads required for anaerobic digestion are much lower than those required for aerobic digestion.

4. Reduced sludge-handling costs:Anaerobic digestion produces just one-fifth to one-tenth as much biomass per unit of organic substrate transformed as aerobic processes in an ideal setting, according to study. Because the disposal or treatment of waste sludge can account for up to half of overall waste-treatment costs, anaerobic treatment's capacity to reduce sludge production and hence sludge handling costs is a significant benefit.

What can we do for you?

We at Netsol Water help you upgrade or install a wastewater treatment system that does as much as possible to help you in removing these difficult contaminants from the wastewater you treat.Give us a call and we'll work with you to come up with cost-effective alternatives.

For any assistance or related query,

Call us on +91-9650608473

Or, write us at enquiry@netsolwater.com