What are the advantages of MBR systems?

Membrane bioreactors combine a suspended growth biological treatment technology, such as activated sludge, with membrane filtration equipment, such as low-pressure microfiltration (MF) or ultrafiltration (UF) membranes, for wastewater treatment.

The membranes are utilized to separate solids from liquids, which is a crucial function. Secondary and tertiary clarifiers have typically been used in activated sludge plants to accomplish this.

Vacuum (or gravity-driven) and pressure-driven MBR systems are the two most common varieties. Immersed vacuum or gravity systems are commonly used, with hollow fibre or flat sheet membranes inserted in the bioreactors or a later membrane tank.

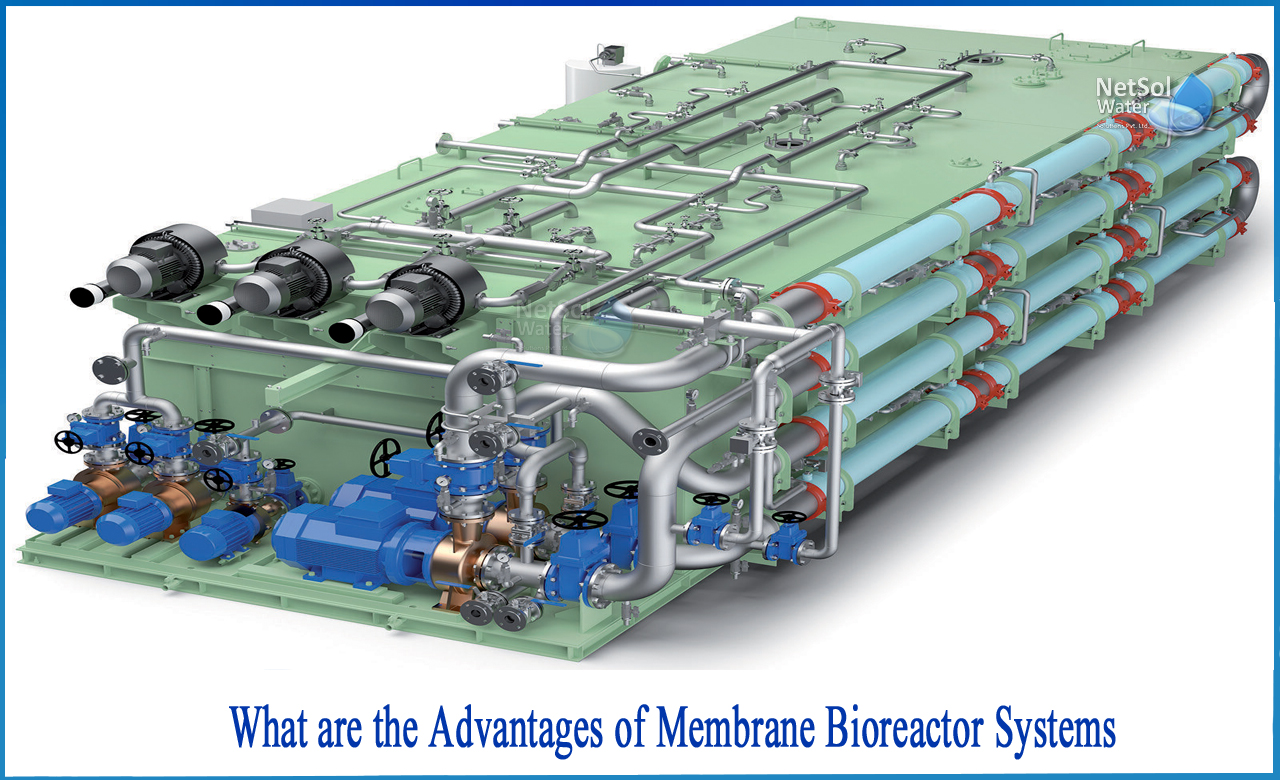

Components of the MBR system

MBR system typically has ten or eleven sub-systems, including fine screening (headworks), the Membrane Zone, and, in most instances, a post-disinfection phase.

Membrane Zone, is the first phase of a biological process in which bacteria breakdown contaminants, which are subsequently filtered via a succession of submerged membranes (or membrane elements). Individual membranes are contained in units known as modules, cassettes, or racks, and a functional membrane unit is a collection of these modules. Integral diffusers supply air to continuously scour membrane surfaces during filtration, enhance mixing, and, in certain situations, contribute oxygen to the biological process.

Membrane bioreactors are widely accepted to offer a number of benefits over other wastewater technologies. This technology,

1: Allows the HRT and SRT to be decoupled.

2: Ensures that the effluent is of excellent quality.

3: Has a modest environmental imprint.

4: Better bio-treatment is required.

5: HRT and SRT are being decoupled.

The biological solids are totally retained in membrane bioreactor process, which is a considerable benefit. This implies that the bioreactor's solids retention time (SRT) may be regulated independently of the hydraulic retention time (HRT).

MBR produces High quality effluent

Because of the membrane's tiny pore size (0.5 m), the treated effluent has a very high purity and a substantially lower pathogen content than the CAS method.

MBR procedures give a considerably cleared and disinfected effluent of sufficient quality to be dumped to sensitive receiving bodies or recovered for urban irrigation, utilities, or toilet flushing. It's also of sufficient quality to feed directly into a reverse osmosis system.

MBR Systems have a smaller footprint

The plant footprint is influenced by solids retention in the reactor and the increase in SRT to create larger biomass solids concentrations. Because of the higher concentrations, the same total mass of solids is stored in a smaller container, resulting in a smaller footprint.

MBR Systems improve bio-treatment

Finally, longer solids retention periods are associated with improved bio-treatment. The circumstances favour the growth of slower-growing microorganisms, particularly nitrifiers. MBRs are very good at biologically removing ammonia ('nitrification').

While MBR technology isn't always the greatest wastewater treatment solution but it is increasingly becoming the technology of choice for water and wastewater applications which demand high-quality treated water or have limited space.

Conclusion

MBRs have already been deployed in over 200 countries, and independent industry surveys consistently claim worldwide market growth rates of up to 15%. Confidence in the method appears to be growing as the number and size of reference installations expands, with a number of plants currently exceeding 100 MLD in capacity (stated as peak daily flow).

Although a few established global businesses continue to dominate the industry, the number of technology providers continues to grow. Similarly, the technology itself is still evolving, with more than 70 MBR membrane module solutions in the market today.

What can Netsol Water offer?

Netsol collaborates with a wide range of international organizations to tackle complicated wastewater problems by strategically integrating modern treatment technology with practical solutions.

If you need any technical help and guidance, or simply have a query regarding our wastewater treatment technology solutions, contact one of our expert advisers via phone at +919650608473 or contact via email at enquiry@netsolwater.com