WHAT IS Dissolved Air Flotation (DAF)?

Dissolved air flotation (DAF) is a physical/chemical method that can be used to treat a wide range of industrial and municipal process and wastewater streams. Oils and greases, as well as suspended particles, are widely removed using DAF systems to achieve a range of treatment goals, including:

- Product recycling and repurposing

- To fulfil sewer discharge restrictions, pretreatment is required.

- To lessen the strain on downstream biological treatment systems, pretreatment is used.

- Biological treatment effluent polishing

- Biosolids thickening

Pretreatment of wastewater to remove suspended particles, oils and greases before discharge to a municipal sewer or a biological treatment system is one of the most prevalent DAF uses. An industrial discharger can utilize a pretreatment DAF to fulfil specified oil and grease and/or suspended solids discharge restrictions set by a municipality (e.g., to meet a discharge limit of 100 mg/L O&G, etc.).A pretreatment DAF may be required by an industry to remove impurities (e.g., product solids, oils and greases, heavy metals, etc.) that could harm a biological wastewater treatment system downstream.

In most situations, the wastewater contaminants must be chemically flocculated before they can be removed by the floatation system. DAF pretreatment is utilized in almost every industry. For the removal of biological solids from wastewa+K625ter streams, DAF has proven to be highly effective.

Following are some of the advantages of gravity clarifying over traditional methods:

- Faster implementation and a smaller footprint

- Lower sludge volume due to higher sludge solids concentration (4 percent TS vs. 1 percent TS).

- Ability to bulk substances that are prone to floating

- Effluent quality that is more consistent

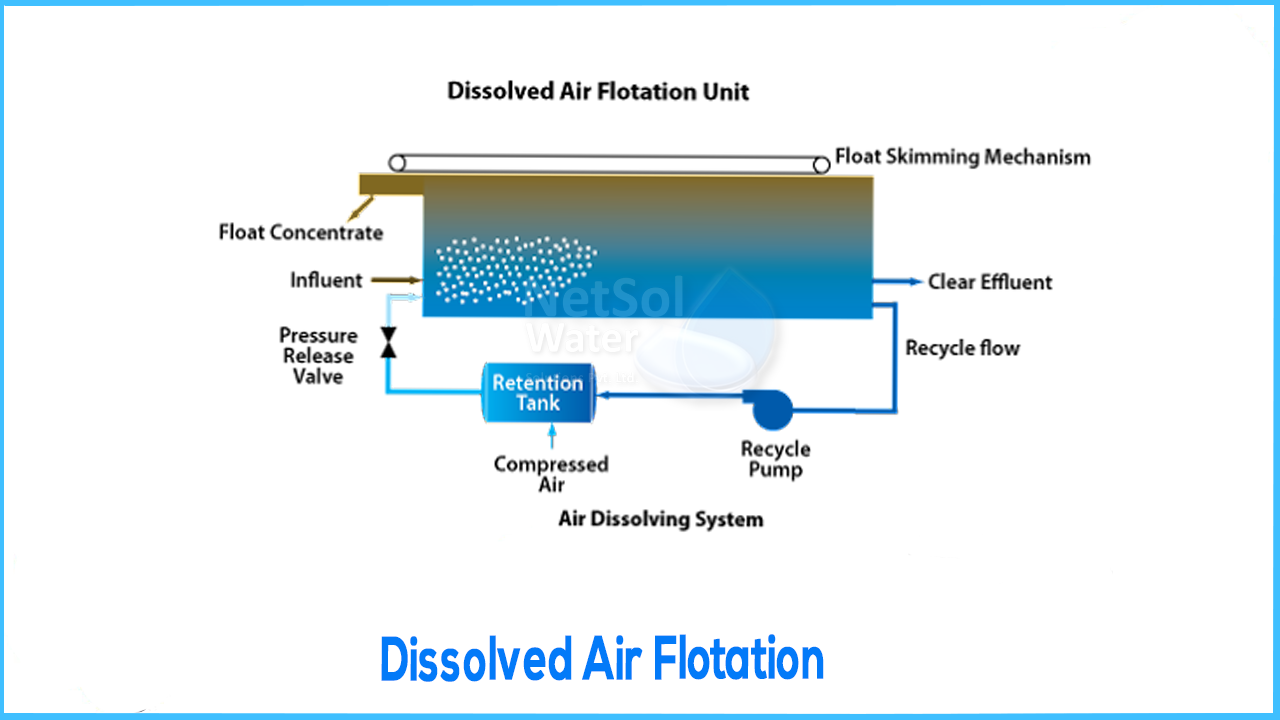

WORKING OF DAF

Bubbles are formed in dissolved air flotation (DAF) when air dissolves in water under very high pressure. The diameter of the bubbles in this procedure is normally between 10 and 100 m. The size of the bubbles, saturator pressure, pH, hydraulic retention period, and recycle flow are all parameters that influence the efficiency of this approach. Collectors can be used to encourage the development of aggregates and a rise in the size of microalgal particles (and therefore improve the efficiency of the process). Because the bubbles created in this procedure are smaller than those produced in dispersed air flotation, it is more effective.

However, because it requires pressurized air, this process is more expensive. A modified version of the DAF process, known as PosiDAF, is available in addition to the standard DAF process. Due to the presence of chemicals in the saturator, the bubbles created in this process are positively charged. Surfactants, coagulants, or polymers with a hydrophobic and hydrophilic portion can be utilized in the saturator to increase the bonding between cells and bubbles.