What are screening and straining in Sewage Treatment plant?

Screening or strainers are excellent for separating bigger particles from water and are a basic yet adaptable technique for a wide range of applications. These function well at (inlets to) central treatment facilities, but their ease of usage makes them appropriate for dispersed or rural applications. They can be installed at surface water inlets to keep debris and coarse particles out of later treatment operations. Debris mostly consists of organic stuff such as leaves, duckweed, and algae. Plastic garbage is common in the neighbourhood of near-urban communities. Debris must be disposed of and handled in accordance with its characteristics and volume.

Sewage Treatment Screening

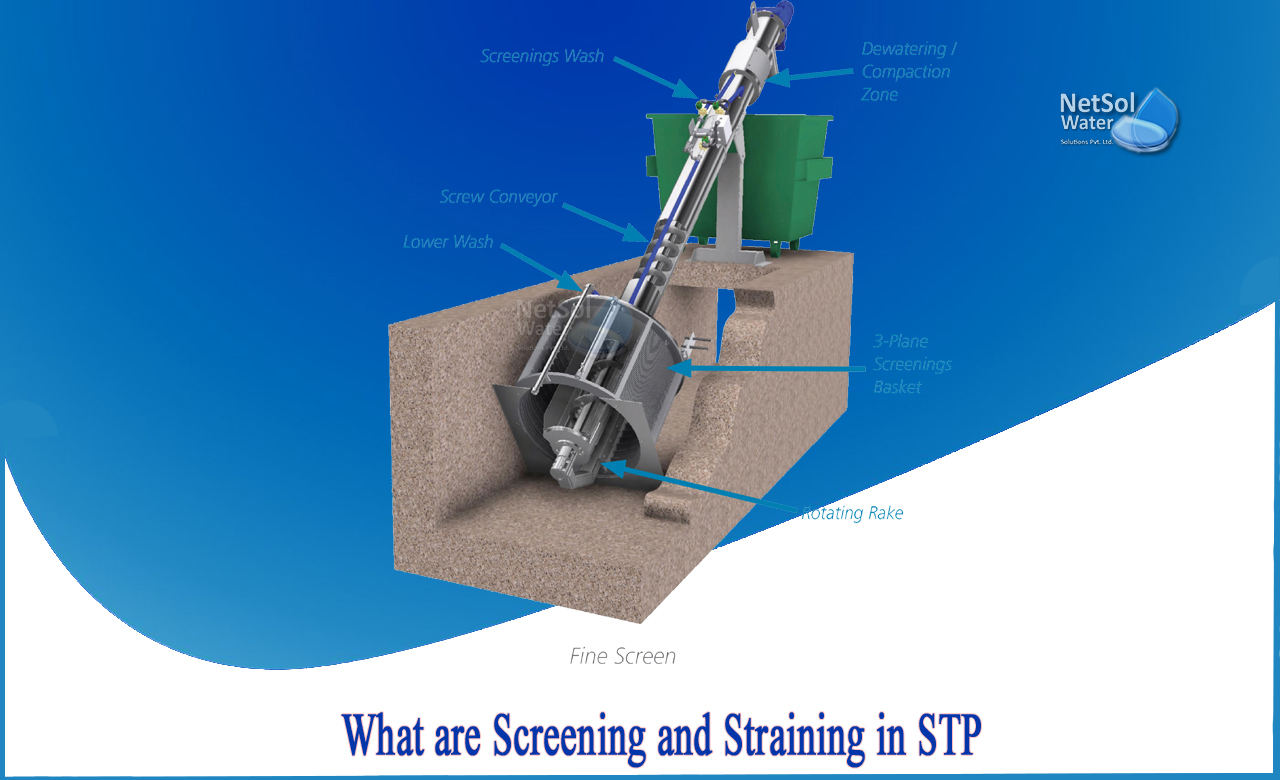

Typically, the first stage in wastewater treatment is the removal of particles from the wastewater flow using screens. The screens eliminated comprise domestic garbage, faeces, toilet paper, and mineral solids. The volume of screenings is determined not only by the separation size of the screen, but also by the type of sewer system.

The particulate percentage of municipal screens ranges from 10% to 25%, depending on the kind of screen. Approximately 90% of the solids are volatile (organic).Because of their high-water content, screens must be treated before they can be disposed of due to their heterogeneous composition and unappealing look.Washing and compaction using a wash press is the most effective screenings treatment procedure. Faeces and other organic elements are removed and reintroduced into the wastewater flow. As a result, a good wash press boosts the BOD-5 load to the biological treatment process by around 6%.The screens are compressed after washing to minimise water content and improve solids concentration. The elimination of organic compounds during washing improves dewatering. A high-quality wash press may reduce weight and volume by up to 80%.

Such wash press minimises the quantity and volume of screens, lowering disposal expenses.

Screening benefits

a. Optimal systems for any application.

b. Dewatering efficiency is quite high.

c. Maximum degree of washout.

d. Costs of disposal are reduced.

Straining in Sewage Treatment

Straining is a relatively basic filtration procedure. Water is passed through a piece of cloth in this operation, which eliminates part of the suspended silt and solids and kills certain germs. Water may not be totally safe to drink after straining, but it can be a drinking water improvement step for individuals who have no other treatment alternatives. A clean cloth is essential since a filthy cloth may bring extra toxins into the water.

The benefits of Straining

• Simple, low-cost technique

• Takes up minimal time

• Lowers turbidity in drinking water

• When administered appropriately, it is known to minimise the risk of cholera.

Screening and straining applications

Freshwater, home usage, and small-scale productive use are all examples of small-scale productive utilization. Screens are increasingly being used in local communities and schools (households use other methods). Surface water is the ideal supply for screens (not rainwater or groundwater).

Maintenance and operation

The screens are often made up of basic steel grids or bigger sheets of screening material. After screens, micro strainers with apertures of 10-60m are employed to remove algae. However, those with a mesh size of 2-8cm are often favoured. Straight screens can be made locally and cleaned by hand. Mechanical cleaning is required for cylindrical or drum strainers (backwashing). They need frequent debris removal, yet a smaller debris load minimises the frequency of cleaning. Cleaning mechanisms determine management needs. Maintenance is minimal and may be done with routine facility cleaning. Debris management training may be necessary.

For more information, contact Netsol Water.