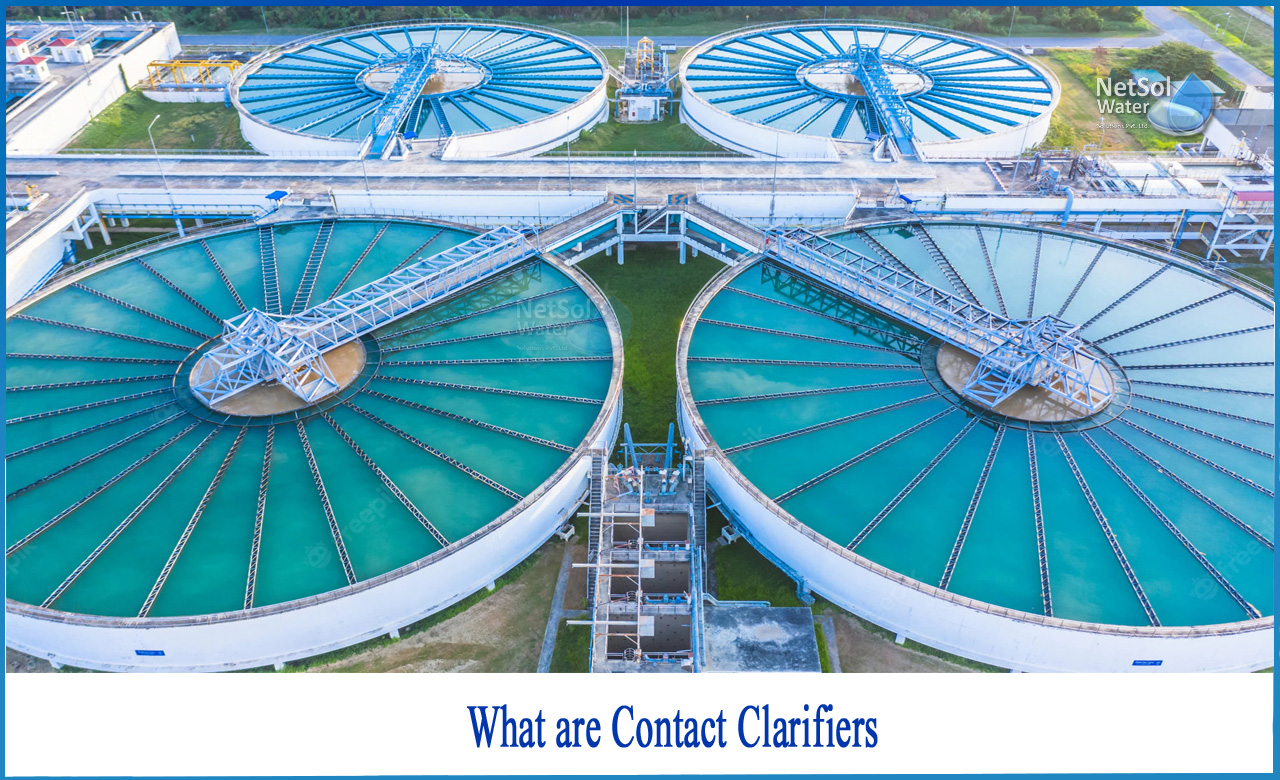

What are contact clarifiers?

Contact clarifiers (also known as contact adsorption clarifiers) are designed to do both flocculation and clarity in one step. These clarifiers are made up of a basin filled with adsorption media, which is usually plastic or pea gravel-sized rock.

Hydraulic mixing induces flocculation when water travels through the media, and the flocculated particles attach to the surface of the media particles. To remove the solids, the media is backwashed with air and water on a regular basis.

The concepts of solids contact flocculation are combined with the impeded settling of flocculated particles in this method of clarifying.

After the wastewater has been coagulated, it is placed in contact with the pre-existing sludge: there is a much greater chance that the colloids in the wastewater will collide with the floc from the sludge blanket, resulting in a dramatic increase in flocculation and sedimentation rates, hence the equipment's designation of accelerated clarifier.

Because the flocculation zone is an inherent and optimized element of the equipment, these are flocculation-settling tanks. The fact that these clarifiers have a sludge concentration zone separate from the actual sedimentation zone, is critical: the latter is only affected by the rectilinear component.

These concepts can be implemented in two ways:

1: Clarifier for sludge recirculation

Sludge that has been cleared and, if necessary, skimmed is re-injected into the wastewater to be treated in order to achieve the best possible mixture.

This recycling can take the form of-

• Either external: Sludge is recovered as it thickens using a pumping system which does not damage the floc and the recycled sludge is re-injected into the flocculation reactor.

• Or internal: The same mechanism (screw, turbine, injector, etc.) used to return sludge to the flocculation zone is also utilized to create the turbulence essential for flocculation to occur.

2: Blanket clarifier for sludge

Flocculation and clarifying are fully integrated into units that operate on this principle, with the sludge blanket serving as the primary flocculation and settling zone.

During clarifying, coagulated water percolates vertically upwards through the flocculated materials. Some of these units are made up of inverted pyramidal cells with a hose injecting the clarified water into the base.

In contrast, if coagulated water is evenly distributed across the whole floor area of a flat-bottomed tank, the vertical streams will be quite vertical and generated by identical upward velocities at every location in the sludge blanket.

This blanket then has a certain cohesiveness, allowing it to accept rising velocities greater than those experienced by an isolated floc.

This cohesiveness explains the sludge blanket's "plasticity," which, like a spring, compresses under gravity (particle sedimentation) but expands to a greater or lesser amount under the action of the water's flow. The sludge blanket's sedimentation rate will no longer be sufficient if the rising velocity is too great, and the diffuse floc will be drawn away with the water.

The sludge cohesion coefficient can be used to calculate the cohesion of a sludge blanket. As a result, this is a critical sludge blanket clarifier design parameter.

If you want to know more about Sludge Contact Clarification, then you are at the right place!

You can have an expert solution upon contacting Netsol Water, a leading manufacturer of Industrial and Commercial Water treatment plants and Wastewater treatment plants, among other services. Our treatment systems are very effective at removing all types of chemical, physical, and biological pollutants.