What are components of a sewage lift station?

These are the elements that should be included in the design of any commercial sewage lift station:

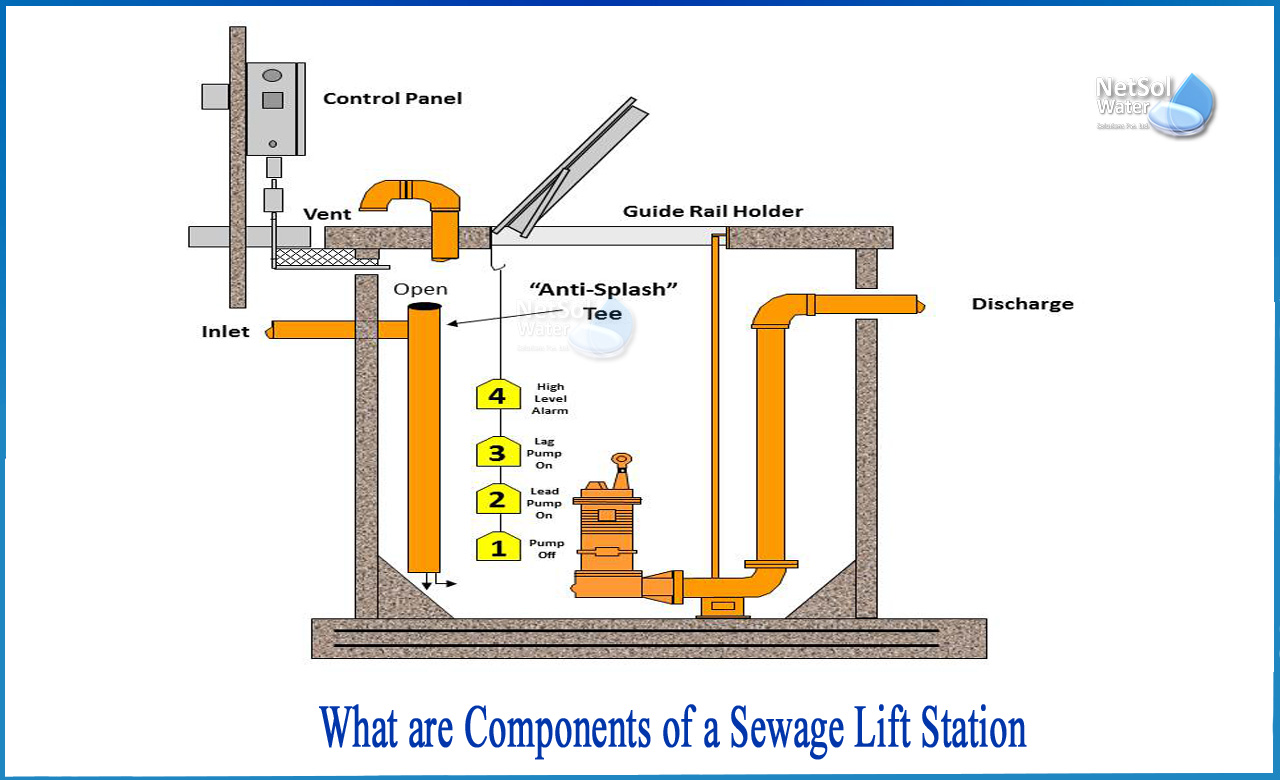

1: Pump and motor for sewage/sump: A submersible pump and motor (which is more frequent) or a vertical pump and motor are the two options. Between a submerged sewage pump or sump pump and a normal vertical motor installed above the sump cover, vertical pumps feature an extended enclosed shaft. When there is a lack of vertical space in the basin, vertical pumps and motors are usually used. They also allow users to service the motor without opening the basin and lifting the sewage/sump pump out, and they normally use off-the-shelf motors. To remove this sort of pump, make sure you have enough vertical space. Pumps and motors that are submersible are meant to be completely submerged in the liquid within the basin.

2: Basin (Concrete or Fiberglass):The sewage is collected in the basin, which also houses the pump (s). The engineer must size the basin to meet the job's requirements and select the optimum construction material, which is commonly concrete or fibreglass, though basins can be made of a variety of materials.

3: Valve Box: Each pump's on/off valves and check valves are housed in the valve box. They are usually placed outside the basin so that they may be accessed without having to go into the sump. Inline on/off valves and check valves can also be positioned above sump or sewage pumps without the box but above the basin cover, which is the more frequent valve layout. Engineers should, however, double-check if this is permissible under local regulations.

4: Electric Panel and Level Controls: The float level controls, as well as the pump controls, should be represented in the drawings. According to the location environment, the control enclosure should be an appropriate assembly (indoor, outdoor, corrosive, etc.) The precise location of the float controls should be noted in the designs as well.

5: Guiderail System/Removal System: Submersible pumps must have a removal device to avoid having to maintain them from inside the pit. These guide rails make it possible to remove the pumps by chain in a stable manner. Engineers should specify stainless steel chains for hoisting instead of galvanised chains, which can corrode in a sewage environment.

6: Wet Well Covers: Wet well covers are attached to the basin's top. These coverings are normally composed of fibreglass or steel and come in round, square, and rectangular shapes. The measurements of the covers, as well as the covers themselves, should be included in the blueprints.

7: Hatches and Access Frame: On the wet well cover, the hatches are installed. They're the access doors that allow the pumps to be removed for inspection. They're usually composed of metal and attached to frames or curbs. Obviously, the hatch must be large enough to accommodate the removal of all submersible equipment from the pit.

8: Anti-Splash Tee: This is not a need, but rather a veteran's technique for avoiding unnecessary float servicing. The sewage is sent directly to the bottom of the sump by installing a tee at the basin's inflow and connecting it to a pipe that runs into the basin's depths. This prevents solids from splashing on the surface as they fall into the pit. Splashing might clog the floats, necessitating maintenance. Anti-splash tees are a simple and inexpensive solution to solve this problem, and they're a good idea to include in the plans.

All of the above components should, if possible, be noted in the designs and acquired from the same seller. This ensures that the system runs properly and reduces the odds of an installation problem.

For more details, contact Netsol Water.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.