Reverse Osmosis

Reverse osmosis is highly successful in treating brackish, surface, and ground water for both large and small flows. RO water plant is used in a variety of industries, including pharmaceuticals, boiler feed water, food and beverage, metal finishing, and semi-conductor manufacture.

RO membrane is required for every Reverse Osmosis plant installation, as it is critical to the system's efficient operation. If the membrane is broken, it might result in poorer productivity, higher operational expenses, and poor water quality. As a result, in order for the membrane to function properly, it must be kept secure, clean, and free of pollutants.

How are scales formed in Reverse Osmosis unit?

RO scaling arises when the maximum solubility limit of dissolved compounds in the feed water reaches a limit in the RO unit. They precipitate out of the solution and onto a surface when concentrated further. The following are the most prevalent RO scales:

CaCO3 (Calcium Carbonate), CaSO4 (calcium sulphate), BaSO4 (barium sulphate), Sulfate of Strontium (SrSO4) and Silica (SiO2).

The ability to prevent scale from forming on RO membranes is critical for the effective operation of this advanced water treatment technology.In almost all water treatment applications, controlling scaling would allow ROs to function at higher recoveries.Because of the more efficient use of water supplies, the reduced volume of concentrate waste to be disposed of, and the possible energy savings, higher recoveries are particularly beneficial. Scale inhibitors for reverse osmosis and circulating water systems act in different ways.

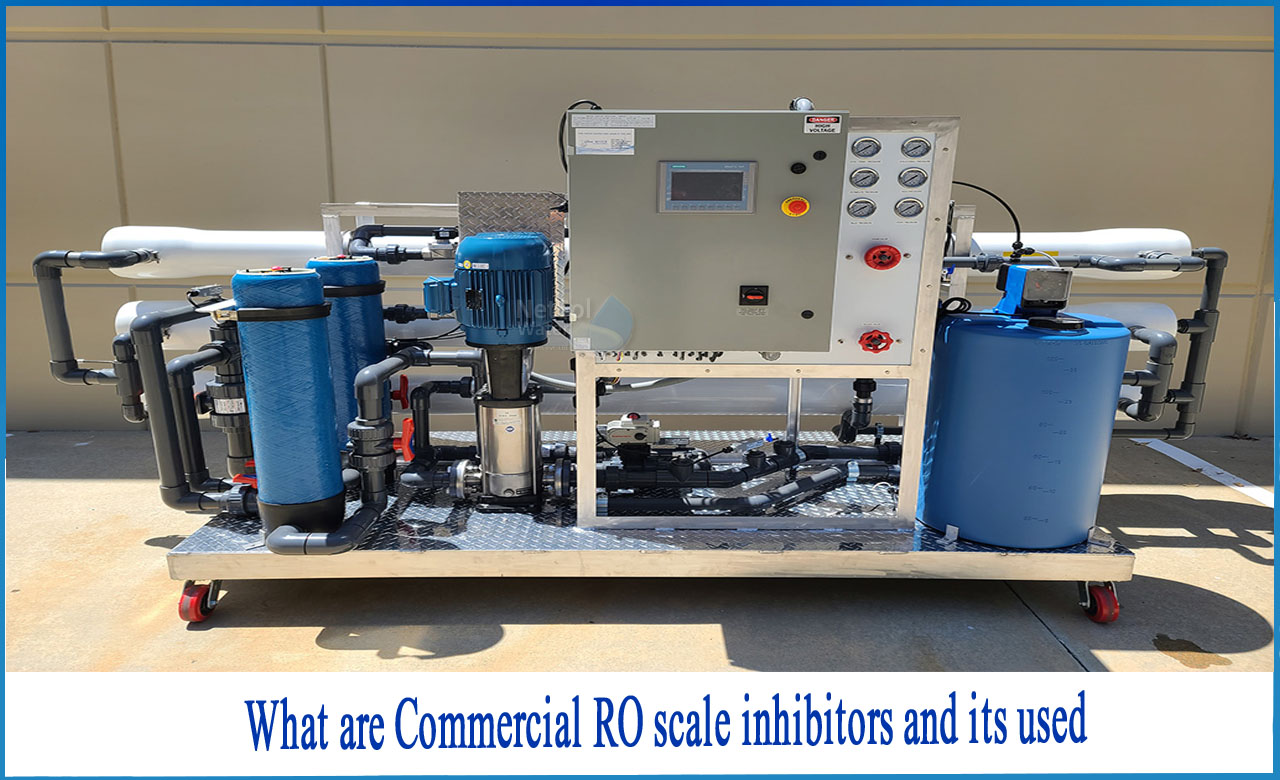

What are Commercial RO scale inhibitors and its used?

Scale inhibitors are a type of chemical that keeps water treatment equipment running smoothly. Inorganic salts that are poorly soluble in water can be dispersed with these agents.

Other functions include:

a) Preventing or interfering with the precipitation of poorly soluble inorganic ions on the metal surface.

b) Ability to decompose scale.

How do scale inhibitors work?

A specifically prepared organic polymer (scale inhibitor) is introduced into the raw water stream to prevent mineral scale formation. This polymer will aid in the dispersal of suspended materials in the raw feed water stream, the alteration of mineral scale crystal formation (morphology), and the sequestration (chelation) of micro-nuclei to inhibit crystal growth.

Some of the early scale inhibitors employed in the RO sector were made up of a single polymer that lost its solubility when injected into specific water sources, such as those containing iron. The RO pre-filter cartridges, as well as the membrane elements, would be heavily fouled as a result of this.

Dosage requirement of scale inhibitors

The concentration of various elements in the brine (concentrate or reject) solution determines the amount of scale inhibitor required to avoid scale development in the RO membrane.

The amount of scale inhibitor required varies by site and is determined by feed flow, raw water analysis, and computer-generated design projections for the RO membrane in use. To avoid scaling, a dosage rate of 2 - 5 milligrams per liter (mg/L) of scale inhibitor/dispersant is usually sufficient.

Are you looking for the best commercial and industrial RO Plant manufacturers in India?

Netsol Water offers various range of Reverse Osmosis systems and their maintenance services. We as water treatment experts, can help you with water reuse and conservation in your operations, as well as the optimization of existing water production and the design and building of new, energy-efficient, and environmentally friendly water and wastewater treatment systems. Our products and solutions can provide the water your plant requires at every stage!

If you need an advice or assistance on selecting the best water and wastewater treatment unit, call us on +91-9650608473 or write us at enquiry@netsolwater.com