Explain Wastewater Treatment Plant Diagram

A Wastewater treatment plant plays a key role in keeping communities healthy and keeping rivers, lakes and coastal waters clean. A treatment plant takes water that people use and treats it so that it no longer harms people orany form of life. The process removes solids, harmful organisms and lowers chemical levels so that the water meets safety rules. A well planned plant also recovers resources and cuts energy use. Many towns and industries depend on a reliable plant for safe disposal and reuse of water. Planning, design and correct operation shape how well a plant serves a city or a factory. Workers, engineers and local leaders must work together so a plant runs smoothly and keeps costs reasonable.

Overview and purpose

A clear view of the purpose helps to set up the full picture of a Wastewater treatment plant and why societies build one. Let us have a look on some main goals and functions of a treatment plant and how each goal shapes the design and the daily work.

Protecting public health

A plant removes disease causing organisms and reduces harmful chemicals so that water no longer spreads infection. Engineers design treatment steps to cut bacteria, viruses and parasites to safe levels. Operators run tests and follow rules so that treated water meets health standards.

Protecting the environment

A plant reduces pollution that would harm fish, plants and birds. It lowers nutrients that cause algal blooms and cuts solids that cloud water and smother bottom life. A well run plant returns water in a way that helps rivers and lakes stay balanced.

Supporting reuse and industry

A plant can make water safe for reuse in irrigation industry and even for some drinking uses when advanced steps follow. This support reduces the demand on fresh water sources and helps industries keep a steady supply.

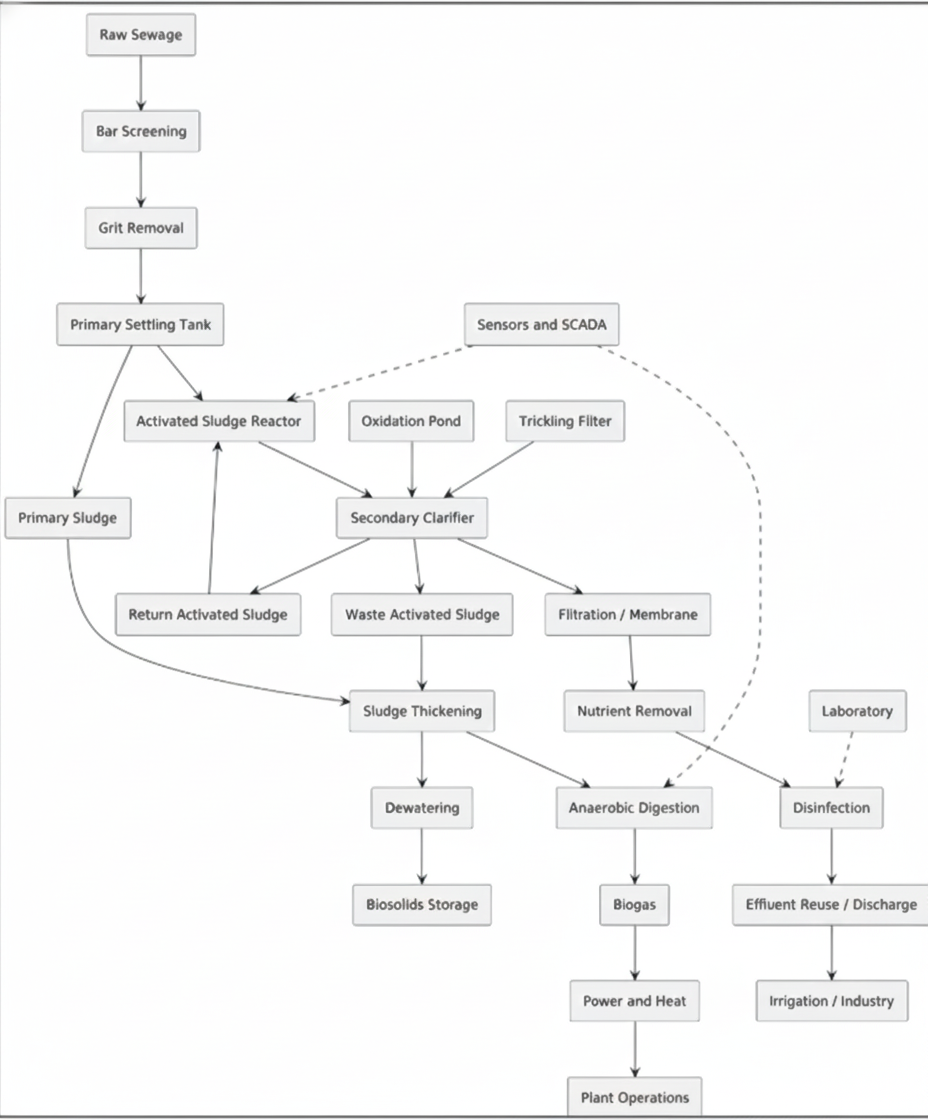

Wastewater treatment plant diagram

Primary treatment processes

Understanding primary steps shows how a plant handles raw wastewater to remove larger matter and to prepare the flow for deeper cleaning. This part sets the stage for later steps that remove dissolved and microscopic material. Let us have a look on some physical processes that act early in the treatment line and why they matter.

Screening and grit removal

Screening takes out large objects that could block pipes or damage machines. Operators place screens at the channel entry to trap items and then remove them for safe disposal. Grit removal settles sand stones and heavy particles so they do not wear out pumps and tanks. Both steps keep the plant safe and reduce maintenance work over time.

Sedimentation and settling tanks

Sedimentation lets heavier organic solids sink to the tank floor while clearer water flows on. Settling tanks collect sludge at the bottom for later treatment and return the cleaner water to follow up processes. These tanks shape the flow and reduce the load that the next biological steps must handle.

Sludge handling at early stage

Sludge from primary tanks contains much of the solids and some organic material. Plants pump this sludge to thickening or digestion units. Handling primary sludge well lowers odours and helps the plant use later steps to recover energy or to produce soil friendly biosolids.

Secondary treatment processes

Secondary steps use biological and chemical action to cut organic matter and to reduce harmful compounds that remain after primary cleaning. Thismatters because the bulk of pollution reduction happens here and it shapes the quality of the final discharge. Let us have a look on some common secondary methods and how they work in detail.

Activated sludge systems

Activated sludge uses bacteria and small organisms to eat organic pollution. Engineers keep air and nutrients in balance so microbes thrive and break down waste. Settling tanks then separate the biological mass from the treated water. Plants recycle part of this mass back to keep the process steady.

Trickling filters and biofilm systems

Trickling filters let water pass over a media where helpful microbes form layers. These layers consume organic matter as the water flows through. This method uses less energy for aeration and can work well for certain flows and climates.

Oxidation ponds

Ponds use sunlight and natural biological action to reduce pollution. These systems need more land but they use less mechanical energy and can handle flows with variable strength. Operators manage pond depth flow paths and harvesting of algae to keep the system stable.

Tertiary treatment and disinfection

Tertiary steps give the final polish and remove nutrients and microbes to meet stricter rules or to prepare water for reuse. This matters when a plant must reach very high water quality or when it returns water to sensitive ecosystems. Let us have a look on some tertiary methods and how they help reach safe and clear water.

Filtration and membrane systems

Filtration removes fine particles that pass earlier steps. Membranes can block tiny microbes and many dissolved pollutants. Engineers choose filters or membranes based on cost and the quality targets. Careful cleaning keeps these systems effective over time.

Nutrient removal

Removing nitrogen and phosphorus prevents excess algae growth in receiving waters. Biological nutrient removal uses controlled zones where microbes convert nitrogen forms to harmless gas and where phosphorus binds to solids for removal. Chemical dosing can also help form solids that remove phosphorus.

Disinfection methods

Disinfection kills harmful microorganisms so that treated water meets public health rules. Common methods use chlorine, ultraviolet light or ozone to inactivate bacteria and viruses. Operators balance dose and contact time to protect health and to limit harmful by products.

Components and plant layout

Knowing the common parts and their order helps anyone to read a plant plan and to follow daily operations. The layout matters because it affects flow rates maintenance access and the ease of upgrades. Let us have a look on some standard components and how they fit together to form a working plant.

Inlet works and pretreatment

The inlet houses screens and grit chambers and sets the baseline quality that enters the main units. Designers place these parts to allow safe removal of large items and to reduce wear on later equipment. Proper inlet design lowers downtime and improves worker safety.

Treatment tanks and biological reactors

Primary settling tanks, secondary reactors and tertiary units follow in a logical sequence so each unit prepares the flow for the next. Reactors hold water long enough for biological action and for solids to settle. Good layout keeps pipes short and avoids dead zones where solids could build up.

Sludge processing and storage

Sludge thickening, digestion, dewatering and storage take up a large space in many plants. These parts prepare solids for final use or disposal. Efficient sludge handling cuts transport costs and can create opportunities for energy recovery.

Operation, maintenance and monitoring

Daily operation and careful maintenance keep a Waste Water treatment plant reliable and safe for years. Skilled staff and clear routines prevent failures and keep treated water within rules. Let us have a look on some practices and tools that operators use to keep systems steady and to catch faults early.

Routine inspections and preventive maintenance

Operators follow schedules for checks, cleaning and parts replacement so that pumps, motors and valves last longer. They log findings and adjust plans to avoid sudden breakdowns. Preventive work links directly to lower repair costs and to steady treatment performance.

Process control and automation

Modern plants use sensors and control systems to monitor oxygen levels flow rates and pollutant load. Automated control keeps conditions within target ranges and alerts staff when values shift. This approach supports timely action and helps keep the plant efficient.

Sampling, testing and record keeping

Laboratory testing checks that treated water meets limits for bacteria, nutrients and chemicals. Operators gather samples at defined points and record results. Clear records show trends help with reporting and guide improvements.

Energy recovery and sustainability

Making a plant greener reduces running costs and lessens the carbon impact of treatment. Let us have a look on some techniques that turn waste into power and that reduce the footprint of a plant.

Anaerobic digestion and biogas

Anaerobic digestion breaks down sludge without oxygen and creates biogas that plants can use to generate heat or electricity. This step cuts sludge volume and provides a renewable energy source. When operators capture and use the gas a plant lowers its fossil fuel use and its cost of operation.

Heat recovery and reuse

Plants often produce warm water or hot gases that they can reuse for heating digesters or office space. Recovering heat reduces energy bills and keeps internal systems at stable temperatures. Careful design links heat sources and users with minimal extra piping.

Water reuse and circular approaches

Treating water to higher standards supports reuse in irrigation industry and cooling systems. Reuse reduces pressure on freshwater sources and extends the value of each drop. A circular approach looks at nutrients and organic matter as resources to recover and use as soil enhancements or as energy feedstock.

Conclusion

A Waste Water treatment plant stands as a practical solution that protects health, conserves water and supports a cleaner environment. Good design, careful operation and green upgrades will keep a plant effective and affordable. If you want more detail on designing a plant, improving an existing plant or exploring options for energy recovery please get in touch for more information or request a consultation. Contact our team to discuss plans, costs and timelines and to start a clear path toward better water management. We can help with studies designs and training so your plant works well and serves your community for many years.

Contact Netsol Water at:

Phone: +91-9650608473, Email: enquiry@netsolwater.com