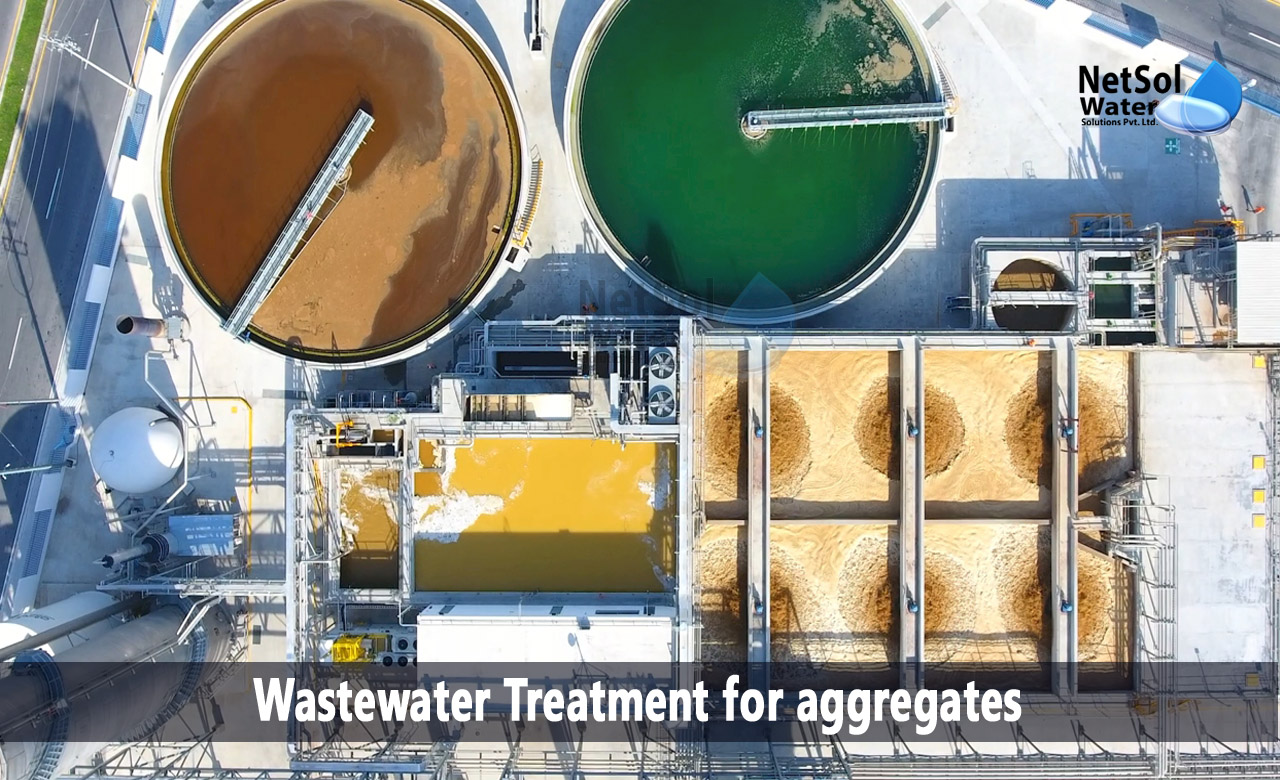

The aggregate business is dependent on four heavy-duty aggregate equipment subsystems operating continuously. This equipment aids in the fundamental manufacturing operations of crushing, screening, transporting, and washing, which are used to make saleable products.

However, maintaining your equipment is a constant problem, particularly in the demanding operating conditions of aggregate production, and there is considerably huge amount of wastewater produced during the aggregate processing, for which wastewater treatment is necessary.

What are aggregates?

Aggregates such as gravel and sand must be washed to recover small particles and remove silt, which adheres to their surfaces. Typically, sand washing water can be recycled by employing settling ponds in which heavier particles settle, and are collected from the bottom to be supplied.

Recovery and storage of these materials, which must later be disposed of with excavators, trucks, and workers, incur enormous costs for the aggregate manufacturing business, due in part to the need to allocate a huge area to these operations.

What does aggregate include?

Sand, gravel, expanded clay, vermiculite, and perlite are all examples of aggregates, as is any crushed material utilized in building construction. They can be found in materials including cement, bituminous conglomerates, and plasters.

Types of aggregate filter equipment’s

1. Crushers

The majority of aggregate production begins with the crusher, which reduces the size and form of raw materials to fit certain product specifications. To break down the raw material into progressively smaller sizes and shapes, all crushers use impact or compression.

Various stages of crushing

Crushing may involve some or all of the following steps, depending on the operation and desired end product: primary, secondary, tertiary, quaternary, and final. Crushers use either a back-and-forth or a rotating motion to reduce material.

2. Screens

Between crushing steps, a screening process divides the aggregate into different sizes for further reduction or for a final product. A vibrating, adjustable screen operated over a bin is the most popular screening methodology.

How to work Wastewater Treatment for aggregates?

1- Water Clarification

A wastewater treatment plant cannot function without the clarifying process. Unlike filter press filtration, clarifying is a continuous process that separates water from the solid particles suspended in it. Netsol Water can design and manufacture vertical and horizontal decanters, out of stainless steel or concrete for its customers.

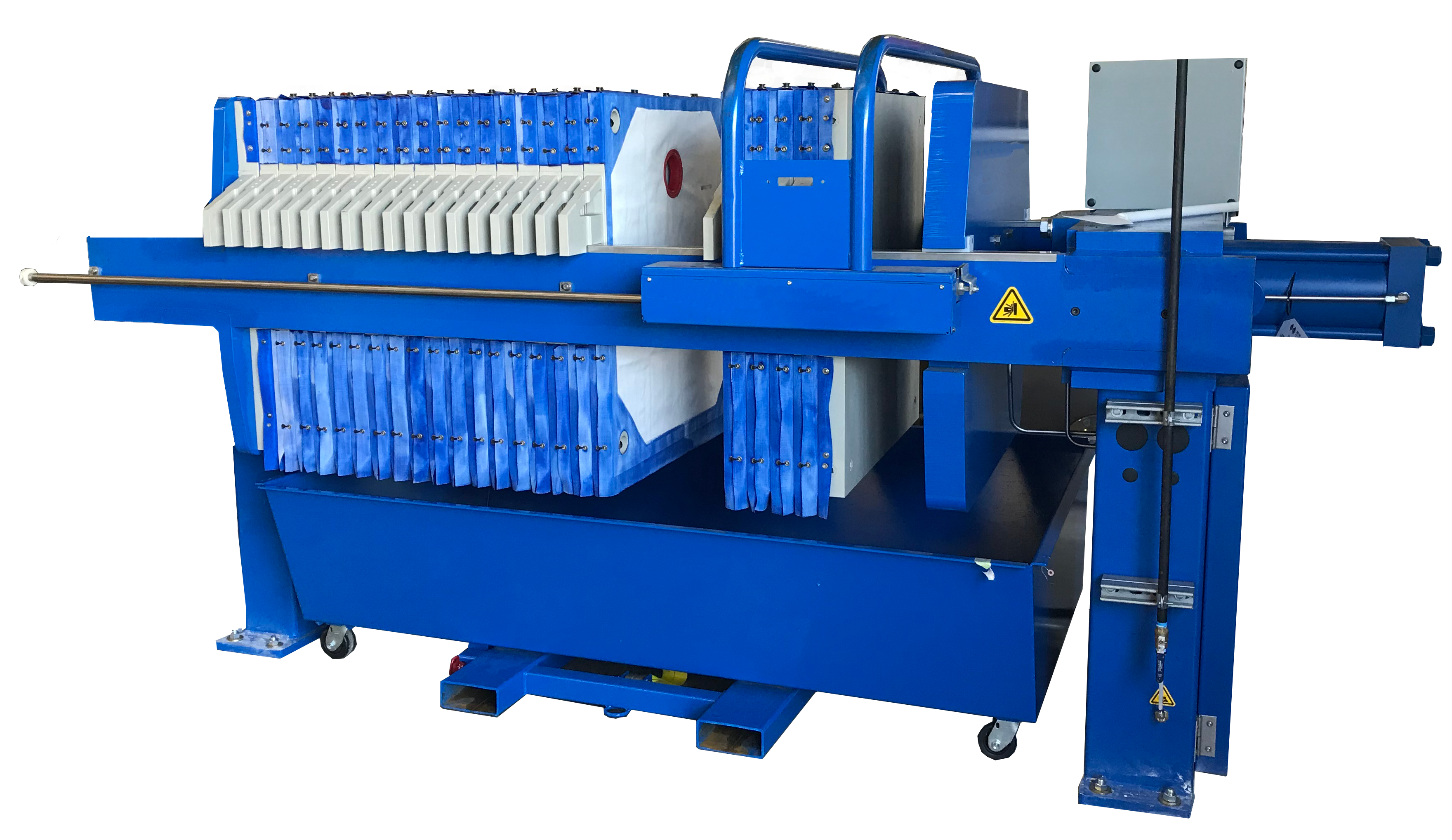

2- Filter Presses

One of the oldest and most trustworthy forms of dewatering equipment is the filter press. It is used in a variety of industries and wastewater treatment applications. A filter press removes impurities and suspended materials from industrial waste, while also separating particles from liquids. Plant managers may handle and dispose of rubbish, while also restoring clean water to their systems.

Our filter presses are constructed of single-block steel from thick slabs, employing a plasma, laser, or water-jet production process and only high-quality components, from leading manufacturers.

How can we assist?

Netsol Water has an extensive understanding of the aggregates sector, because our water treatment devices are designed to operate with aggregates, which are difficult to handle. This is why we developed a variety of machinery for washing aggregates, managing the entire process, and ensuring the best output from the washing system and water treatment facilities.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.