How is Sewage System failure caused?

1: Sewer deterioration begins with initial flaws such as sewer pipe overloading, which can lead to sewer cracking. Cracks at the crown, springing, and invert characterize this classic failure. Unfortunately, because the pipe invert is normally submerged, it is difficult to see the crack. The cracks at the springing’s are also obscured because they are in compression at this point.

Finally, the initial failure causes the soil around the pipe to erode due to ground water infiltration and sewage exfiltration. This process gradually washes away soil fines, reducing soil support over time. When this happens, the pipe begins to deform, and the sewer eventually collapses.

2: Sewer failure can also be caused by leaking joints. In this case, an elastomeric seal may fail or the angular deflection may be greater than the joint's capacity. Alternatively, the mortar in a brick sewer can deteriorate over time, allowing groundwater to infiltrate. This causes erosion or loss of ground support, eventually resulting in the sewer's collapse.

Furthermore, displaced joints, as well as a hole or defect in the sewer, can cause sewer failure. This type of failure is typically caused by the use of rods to clean the sewer or by a third party excavating near the sewer.

3: The ingress of tree roots or vegetation may cause sewer blockage. An intruding lateral connection is another type of failure that can easily cause the sewer to become clogged.Finally, failure can be caused by mortar loss, resulting in displaced or hanging brickwork but in some cases, damage can also be caused by animals, such as rats.

The pipe in the ground is the water industry's most valuable asset, and because excavation and backfilling of trenches account for a large portion of the cost of replacing sewers, renovation techniques typically operate from existing manholes, allowing cost savings.

There are four general methods for detecting sewer failures

One method is to use closed circuit television (CCTV), while another is to use an air test to apply a leakage test to manhole lengths. A water test can be performed in smaller diameter sewers. There is also the option of performing a localized test on the individual pipe joints of the sewer.

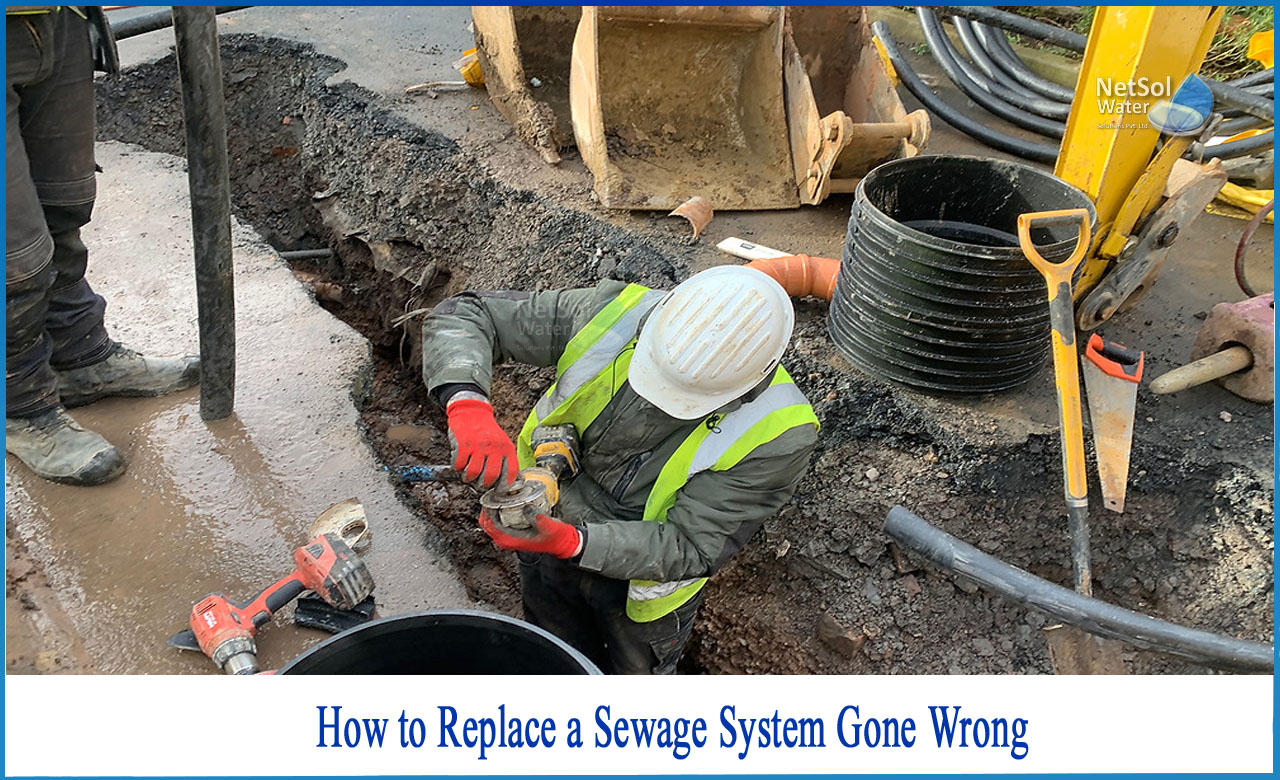

The Solution: The Procedure to Replace Sewage System

>Replace it with a new pump station that includes new internal pumps and pipework to handle waste from the pump station's nine properties.

>To ensure adequate capacity, it is usually decided to install a 9,050 liters tank in households with submersible grinder pumps. The control panel must be replaced with a suitable unit while retaining the existing brick-built structure.

>Ensure that any disruption to residents is kept to a minimum during the construction. For example, use road plates and temporary backfill of trenches to ensure they can still access their driveways.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.