What are the different types of anaerobic digester?

Microorganisms break down biodegradable materials in the absence of oxygen through a series of processes known as anaerobic digestion. The method is used to manage trash and produce fuels in both industrial and home settings. Anaerobic digestion is utilised in a lot of industrial and home fermentation processes to make food and drinking items. The treatment of biodegradable waste and sewage sludge includes anaerobic digestion. Anaerobic digestion, as part of an integrated waste management system, minimises landfill gas emissions into the atmosphere.

Anaerobic digestion is a popular renewable energy source. Methane, carbon dioxide, and traces of other 'contaminant' gases are produced during the process, which results in biogas formation. This biogas can be used in engines, or converted to biomethane of natural gas quality.

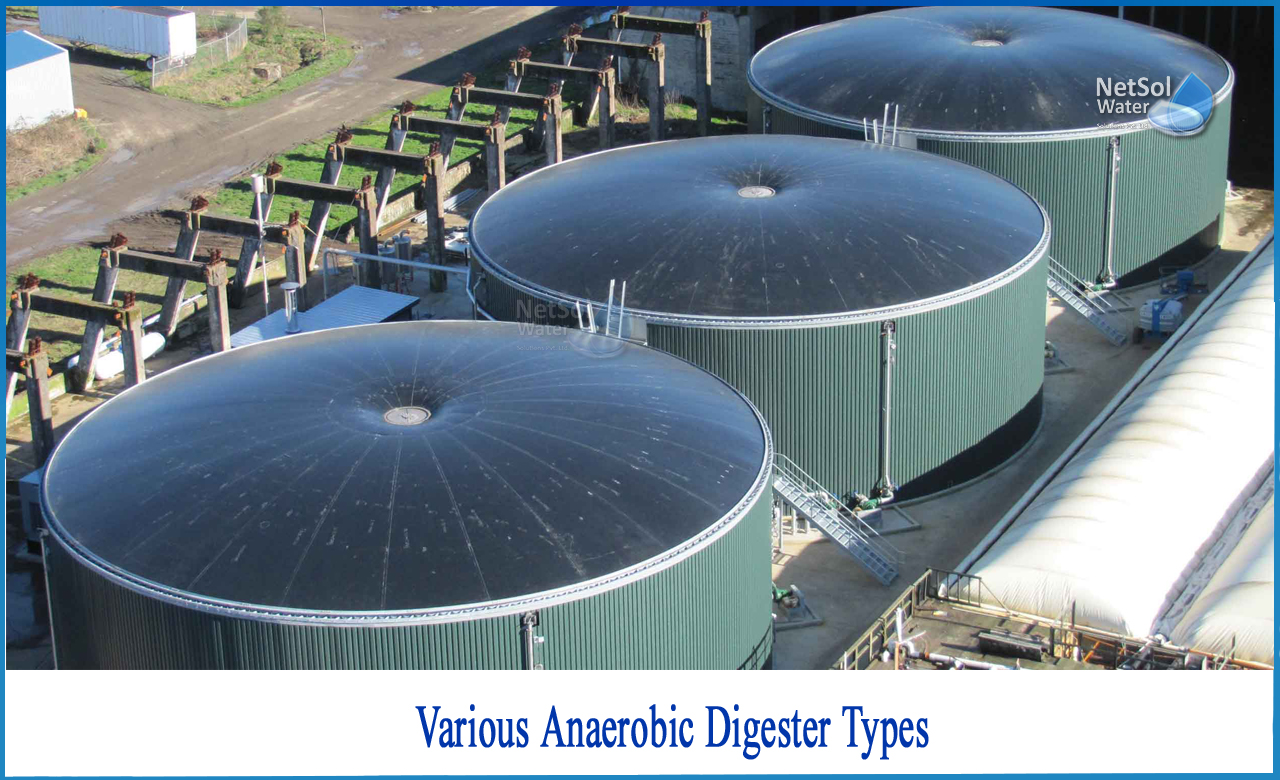

Here is a partial list of various anaerobic digesters:

1: Plug flow anaerobic digester

The Plug flow anaerobic digester is a rectangular, unmixed, heated tank that digests raw dairy farm waste. Scrapings of manure are collected and fed into the digester, where it degrades as it passes through the tank. The top of the tank is covered with an impermeable substance to capture the biogas.A mix tank, a digester tank with heat exchanger and biogas recovery system, an effluent storage structure, and a biogas utilisation system are all common components of a plug-flow digestion system. Separation of solids after the digester is optional.

2: Submerged media anaerobic reactor

The submerged media anaerobic reactor is a low-cost waste water treatment and sewage sanitation system that is commonly found in residential and commercial buildings.

The three steps of this technology are Primary Settlement, Secondary Treatment, and Final Settlement. This technology is viewed as a simple and cost-effective form of commercial and residential sewage sanitation/waste water treatment in the wastewater sector, particularly for small to medium-sized treatment plants with limited area and where full-time operational manpower would be uneconomical.

It is a process that is used to reduce the organic loading of residential and commercial sewage/waste water, thereby lowering the Biological Oxygen Demand (BOD) and a significant amount of Suspended Solids (SS) that would otherwise contaminate rivers and sea outfalls if left untreated; in other words, it is used to significantly improve effluent discharge quality.

3: Sintex digester

The first stage of the Sintex digester converts influent solids to settled solids while allowing scum to float to the surface. It's a septic zone where anaerobic digestion stabilises settled sludge.

The treatment efficiency of the chamber is in the range of 30-40% BOD removal. The aerobic zone, in which air bubbles pass through plastic media installed inside the tank, increasing the surface area and retaining microorganism long enough to digest the organic substance remained, is in the second stage.

Blowers give air, and the longer the slime remains in touch with the plastic media, the more efficient the digesting process will be. Around 60-70% of BOD is eliminated.

4: Solid – state anaerobic digester

Solid state anaerobic digestion is a two-step method that produces biogas from dry stackable materials by combining dry fermentation with wet methanogenesis. “Bin” and “silo” reactors are used for fermentation. Single-phase systems are those that complete fermentation and methanogenesis in the same reactor. Fermentation and methanogenesis take place in separate reactors in two-phase systems.

For water, wastewater or sludge treatment, Netsol Water Solutions offer a complete spectrum of wastewater treatment products. Our engineers would gladly collaborate with your team to create the right design that meets your budget and objectives.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.