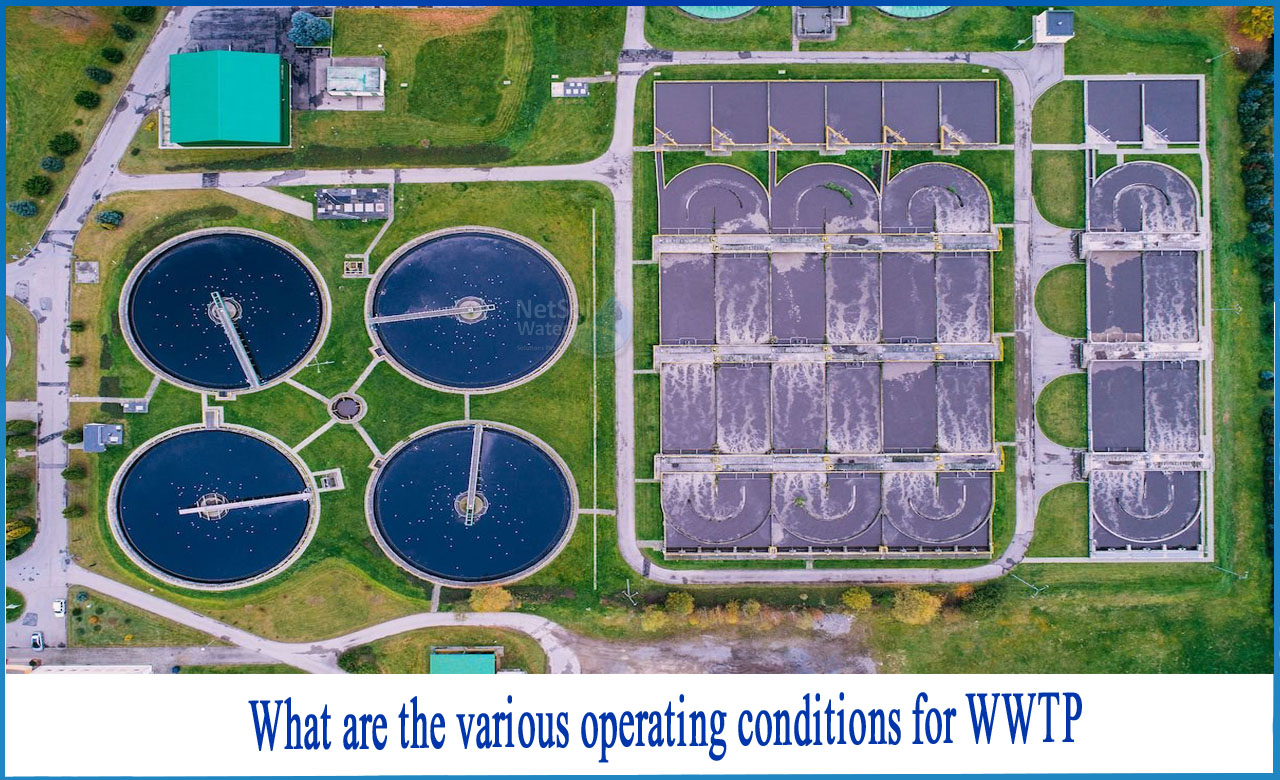

What are the various operating conditions for WWTP?

Our modern existence affords us the luxury of using a variety of technologies to make our lives more pleasant and convenient, but this comes with a cost.

Wastewater is a typical result of our modern way of life, and it can take the shape of water pouring down the drain or runoff from wet roadways. This effluent is unfit for drinking or use by humans. Fortunately, we can make wastewater potable and useable by using wastewater treatment technologies that filter and treat wastewater by removing impurities.

Types of Industrial Wastewater

Effluent is typically classified into three types:

1: The first is organized based on the chemical characteristics of the major contaminants found in industrial wastewater. Inorganic pollutants predominate in inorganic wastewater, while organic pollutants predominate in organic wastewater. Inorganic wastewater includes electroplating effluent and wastewater from mineral processing; organic wastewater includes wastewater from food or petroleum processing.

2: The second classification is based on industrial enterprises' products and processing objects, such as metallurgical wastewater, papermaking wastewater, cooking gas wastewater, metal pickling wastewater, chemical fertilizer wastewater, textile printing and dyeing wastewater, and dye wastewater, tanning wastewater, pesticide wastewater, and power station wastewater.

3: The third classification is based on the main pollutants found in wastewater, such as acid, alkalis, cyanide, chromium, cadmium, mercury, phenol, aldehyde, and oily, sulphur, organic phosphorus, and radioactive substances, among others.

What are the operating conditions of industrial wastewater treatment plants?

Let us go throu?gh the operating conditions of the WWTPs:

1: Ensure that the incoming water volume matches the pumping volume. If the volume of incoming water exceeds the pumping volume and overflow precautions are not implemented in a timely manner upstream, the bubble grids may flood and the sewer with low terrain in the urban area may return water and the equipment will get damaged.

2: The sump should be kept running at a high-water level to reduce pump lift, enhance efficiency, and reduce energy consumption while ensuring pumping capacity.

3: The amount of starts and stops of industrial sewage treatment equipment should not be too frequent, as this will harm the motor and shorten its service life.

4: Because the suction port of each wastewater treatment equipment corresponds to a portion of the volume in the sump, the operation periods and times of eachtreatment equipment in the industrial wastewater treatment should be essentially uniform.

What do we have to offer?

Netsol Water is a renowned producer of water and wastewater treatment plants. Based on client feedback and job quality, we are the most demanding organization in the water industry. We have a reputation for being the top commercial RO plant manufacturer, industrial RO plant manufacturer, sewage treatment plant manufacturer, effluent treatment plant manufacturer, and much more. Aside from that, our USP is 24x7 customer assistance.

For any assistance, inquiry, or product-purchase-related questions, give us a call on +91-9650608473 or email at enquiry@netsolwater.com.