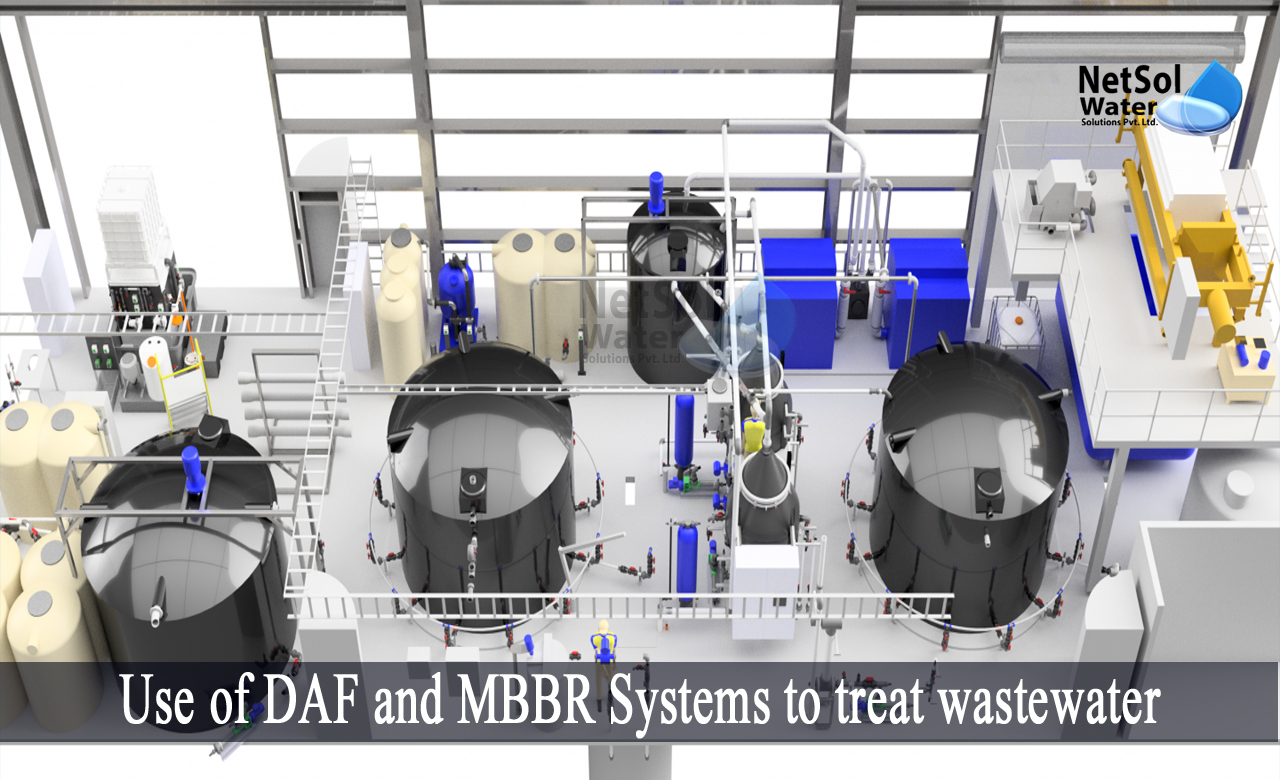

How to treat wastewater using DAF and MBBR System?

Due to their ability to efficiently remove a variety of organic particles from wastewater, without the use of harmful chemicals, DAF and MBBR systems are both ideal for use in the cleaning of wastewater, in meat production facilities. Each system has its own distinct advantages that make it more suitable, than other treatment options in particular circumstances.

Use of DAF and MBBR systems for meat processing wastewaters

Dissolved Air Floatation (DAF) systems

DAF systems are highly good at handling bulk and biological solids in wastewater, and are very reasonably priced. They are an environmentally beneficial treatment option, because they employ water and air solutions to remove solids.

Contaminants removed by DAF Systems

Total suspended solids (TSS), biochemical oxygen demand (BOD), and oils and greases (O&G), are all substances that DAF systems are intended to remove from wastewater streams.

Working of DAF Systems

A dissolved air-in-water solution is used to eliminate contaminants, and it is created by forcing air into a recycle stream of cleared DAF effluent. The dissolved air emerges from the solution as micron-sized bubbles, which adhere to the pollutants, and this recycle stream is then blended and mixed with incoming wastewater, in an internal contact chamber. A surface skimmer removes the floating bed of material made up of bubbles and impurities and deposits it into an internal hopper for further processing.

Moving Bed-Bioreactor systems (MBBR)

For high volume loads or confined spaces, MBBR systems provide full solids removal solutions. Their simplicity of operation eliminates the need for operator engagement and upkeep.

Working of MBBR Systems

A multi-step method for treating wastewater frequently includes MBBR, along with other procedures that concentrate on certain facets of purification. This is why additional procedures, like grit removal and disinfection are frequently included in an MBBR process. To best meet their purification requirements, individual plants might alter, both the MBBR procedure itself and their overall wastewater treatment plant.

Implementation of DAF and MBBR System in the Meat Industry

For the following applications in the meat sector, DAF and MBBR systems are quite effective:

· Activities for keeping and butchering animals,

· Hiding process,

· Production, processing, and preparation of meat,

· Management of edible waste materials

Although these two systems are utilized individually in the aforementioned processes, they can, and frequently are, used in conjunction to treat wastewater more effectively.

Are you still confused about the twotechnologies? Consult an EXPERT!

It can be challenging to choose between DAF, MBBR, or a combination of the two systems, to meet the needs of a meat processing facility, but the staff at Netsol Water, is here to assist. At Netsol, we are aware that every facility has its own specifications and constraints. Since each customer deserves the best system possible for their needs, we offer a wide range of tailored services to that end.

Advantages of Netsol’s Wastewater treatment plant for meat processing sector

Customers in the meat industry, who work with us for their wastewater treatment requirements, gain access to:

1: A wealth of knowledge in developing industrial wastewater treatment solutions, especially for prestigious businesses.

2: Exceptionally knowledgeable group of chemists, engineers, and creators.

3: Comprehensive variety of service skills, including system upgrades, chemical optimization, automation and controls integration, equipment design, construction, and installation, and after-sales service and support.

Combining Netsol’s DAF and MBRR Systems Service

For services related to meat processing and packaging, Netsol Water is a leading provider of technologically sophisticated wastewater treatment solutions, such as DAF and MBBR systems. We are professionals at providing our valued clients with the highest-quality DAF systems, and integrating them into their new and current facilities, as needed. For more automation and more effective treatment, our premium MBBR systems are designed, and produced in-house.