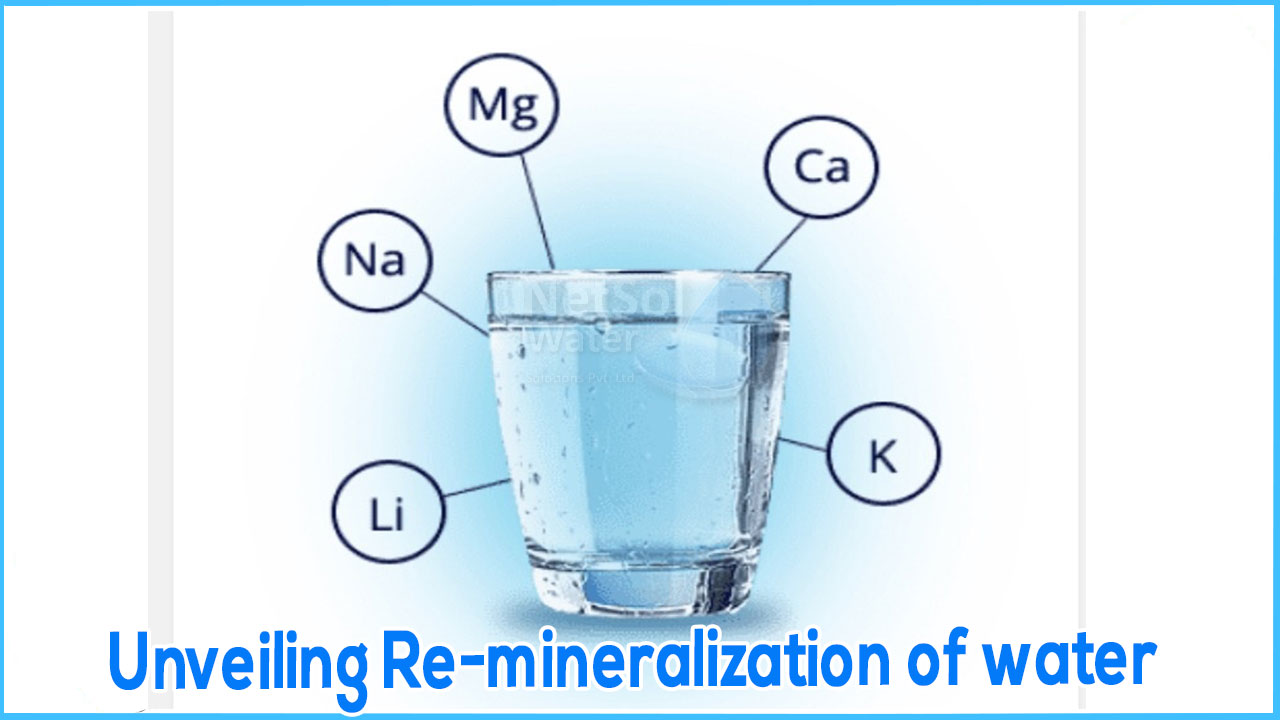

A LOOK AT RE-MINERALIZED WATER!

Remineralized Water that has had some minerals added back to it is called remineralized water. The reverse osmosis method is non-selective, meaning it removes both 'good' minerals like calcium and magnesium and 'bad' contaminants like pesticides, heavy metals, and medicines. Some of the good stuff is added back to the water during the remineralization process. This is commonly accomplished with a calcium or magnesium-based post-filter. Calcite (calcium carbonate) and Corosex are the most commonly used materials (a magnesium compound). Some filters utilise a mix of the two. Before being delivered, the reverse osmosis treated water passes through one of these filters, where it dissolves some of the filtration material. Calcite remineralizers will raise the pH to roughly 7.0, whereas Corosex will raise it above that.

CHEMICAL EQUATION OF REMINERALIZATION:

2CO2 + Ca (OH)2= Ca(HCO3)2

- CO2: It is delivered to industry in cylinders at extremely high pressures and, more commonly, in cooled "low pressure" containers. CO2 can be produced by burning gas (submerged burners) in some industrial installations; however, the contaminants produced by incomplete combustion and/or the original fuel imply that it cannot be used to produce drinking water. CO2 obtained by distilling sea water can be recycled and utilised to remineralize water intended for human consumption when employed in sea water processing.

l.Lime: The purity of lime varies from 80 to 95 percent depending on its origin; consequently, this factor must be considered when estimating not only the quantity to be used, but also how the product will be used.

PROCESS CONTROL

The efficiency of the "lime + CO2" process will be determined by a variety of factors, including:

- Raw water quality: pH, M, alkalinity, OM , temperature;

- The quality of the reagents and/or stock solution concentrations;

- Reagent flow rate: dispensing pump stability.

As a result, it has typically been reserved for major surface water treatment plants that require clarity and, as a result, have more instrumentation and inspection people.

PROCESS LIMITATIONS

-When drilling water comes into contact with the atmosphere and the pH is elevated, dissolved metal ions (Fe2+, Mn2+) may precipitate. The hydroxides or oxides that form will clog the pores of the medium, causing it to take longer to dissolve.

-The same might be said about colored water that is high in humic acids, these can precipitate as metal compounds or calcium salts, causing the same issues.

Before starting with re-mineralization, preparatory iron or manganese removal using the physical-chemical or biological approach or humic acid coagulation with an iron salt followed by a minimum of sand filtering, will be necessary.