What is the RBCS? Explain with diagram?

Rotating biological contactors (RBCs) are used as a post-treatment process for wastewater treatment. The RBC process removes pollutants from wastewater by contacting it with a biological medium before it is released into the environment (usually a river).

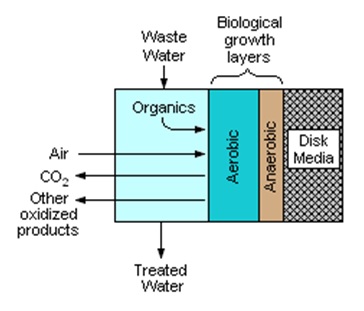

The structure of the RBC consists of a series of plastic discs and media mounted on the drive shaft contained in the tank or pan. Commonly used plastics for media are polyethylene, PVC, and Styrofoam. The shaft aligns with the sewage stream, the disc rotates at right angles to the stream, and several rotors combine to form a processing line.

About 40% of the surface of the pane is submerged in wastewater. The biological growth that attaches to the paneabsorbs organic matter in the wastewater. Ventilation is achieved by a rotational process that exposes the medium to air after contact with wastewater, facilitating the digestion of organic compounds that are removed.

The degree of wastewater treatment depends on the surface of the medium and the quality and quantity of inflowing wastewater. If wastewater is suitable for biological treatment, the RBC process can be used. The RBC process can be used in many ways to achieve varying degrees of reduction in carbon and / or nitrogen oxygen demand. This process is easier to use than activated sludge because it does not require wastewater or sludge recycling. Particular attention should be paid to the return of the supernatant from sludge digestion to RBC.

Benefits of RBC technology include longer contact times (8-10 times longer than trickle filters), more advanced treatments than traditional high-throughput trickle filters, and less sensitivity. Whether it is a small or large plant, the RBC process should be designed to remove at least 85% of BOD from household wastewater. This process can also be designed to remove ammoniacal nitrogen (NH3N). In addition, the RBC process can treat wastewater from dairy products, bakeries, food processing plants, pulp and paper mills, and other biodegradable industrial wastewater.

Selection process of RBC:

Choosing the most appropriate mode of operation is affected by the level and consistency of treatment required, the type of waste treated, site limits, and capital and operating costs.

The process design of the RBC system includes accurate determination of inflow, septic tank, and side-flow loads, drainage requirements, correct media dimensions to meet air requirements, staging and equipment selection, and selection of the overall system layout. As an accurate source of information for the RBC design, a comprehensive on-site pilot plant assessment is recommended to consider the factors that affect RBC performance. Other approaches to determine the expected performance of RBC can be based on results from similar large plants and / or fully documented pilot tests using their respective wastewaters.

The small diameter RBC pilot device is suitable for determining the processability of wastewater. When operating small diameter units to capture design data, each stage below the oxygen permeability of the full-size unit should be loaded to minimize scale-up issues. Direct scaling from small diameter units to full size units is not possible because of temperature, medium peripheral speed, and other process and equipment factors.

For designing and manufacturing of RBC’s, contact Netsol Water!

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.