Ultraviolet/Hydrogen Peroxide Advanced Oxidation in WWTP

In the world of cleaning up wastewater, various treatment ways are being looked for to achieve an effective and healthy environment. One promising method that showed excellent results is advanced oxidation processes (AOPs). A popular version of this is ultraviolet (UV) light and hydrogen peroxide (H2O2) which are used together. This combo, known as UV/H2O2 advanced oxidation, is getting a lot of attention because it's really good at breaking down all kinds of organic pollutants and making wastewater safe to use again.

Understanding UV/H2O2 Advanced Oxidation

The UV/H2O2 advanced oxidation process is a method used to clean up wastewater using special chemicals. It works by creating highly reactive hydroxyl radicals (•OH) that can break down organic compounds in the water. These radicals are formed when UV light breaks down hydrogen peroxide. Once generated, they start a series of reactions that break down pollutants in the water until they're no longer harmful.

The reaction mechanism can be summarized as follows:

H2O2 + UV → 2•OH (Hydroxyl radicals formation)

•OH + Organic Pollutants → Degradation Products (Oxidation and mineralization)

Advantages of UV/H2O2 Advanced Oxidation

The UV/H2O2 advanced oxidation process offers several advantages over conventional wastewater treatment methods, making it an attractive choice for various applications:

1. Effective Removal of Organic Pollutants: The super-reactive hydroxyl radicals made in this process are really good at breaking down lots of different organic pollutants. This includes things like dyes, medicines, pesticides, and chemicals from factories. These pollutants can be tough to get rid of using normal methods, but the hydroxyl radicals can break them down effectively.

2. Disinfection Capabilities: In addition to its oxidation potential, the UV radiation in the UV/H2O2 process also contributes to the disinfection of wastewater by inactivating pathogenic microorganisms, such as bacteria, viruses, and protozoa.

3. No Residual Toxicity: Unlike some chemical treatment methods that may introduce toxic byproducts or residues, the UV/H2O2 process does not generate persistent toxic compounds, making it an environmentally friendly option.

4. Operational Flexibility: The UV/H2O2 process can be easily integrated into existing wastewater treatment plants, offering flexibility in terms of treatment capacity and operational conditions.

5. Cost-Effectiveness: Compared to other advanced oxidation processes, the UV/H2O2 method is generally more cost-effective, as it requires fewer chemicals and has lower energy requirements.

Applications in Wastewater Treatment Plants

The UV/H2O2 advanced oxidation process finds applications in various stages of wastewater treatment plants, depending on the specific treatment objectives and the nature of the wastewater:

1. Pre-treatment: In some cases, the UV/H2O2 process is employed as a pre-treatment step to break down complex organic compounds and enhance the biodegradability of wastewater, making it more amenable to subsequent biological treatment processes.

2. Secondary Treatment: The process can be integrated into the secondary treatment stage, where it can effectively remove recalcitrant organic pollutants and improve the overall treatment efficiency.

3. Tertiary Treatment: UV/H2O2 advanced oxidation is often utilized as a tertiary treatment step, particularly for the removal of persistent organic pollutants, disinfection, and final polishing of treated wastewater before discharge or reuse.

4. Industrial Wastewater Treatment: Many industries, such as textile, pharmaceutical, and chemical manufacturing, generate wastewater containing a variety of organic pollutants. The UV/H2O2 process can be employed to treat these industrial wastewaters effectively.

Process Optimization and Considerations

To make the UV/H2O2 advanced oxidation process work best and be cost-effective in treating wastewater, we need to think about and tweak several things:

UV Light Strength and Time Exposed: How strong the UV light is and how long the wastewater is exposed to it really matters. It helps make hydroxyl radicals, which are crucial for breaking down pollutants. Choosing the right UV lamps, designing the reactor well, and managing the flow rate are key to getting the best results.

Hydrogen Peroxide Amount: We have to be careful about how much hydrogen peroxide we add to the wastewater. If we don't add enough, pollutants might not break down completely. But if we add too much, it's wasteful and could make unwanted byproducts.

Adjusting pH: The pH level of the wastewater can make a big difference in how well the UV/H2O2 process works. Usually, slightly acidic conditions (around pH 3-5) are best for making lots of hydroxyl radicals and breaking down pollutants.

Understanding Wastewater: What's in the wastewater, like organic matter or dirtiness, can affect how well the UV/H2O2 process works. Sometimes, we might need to clean up the wastewater a bit first to get the best results.

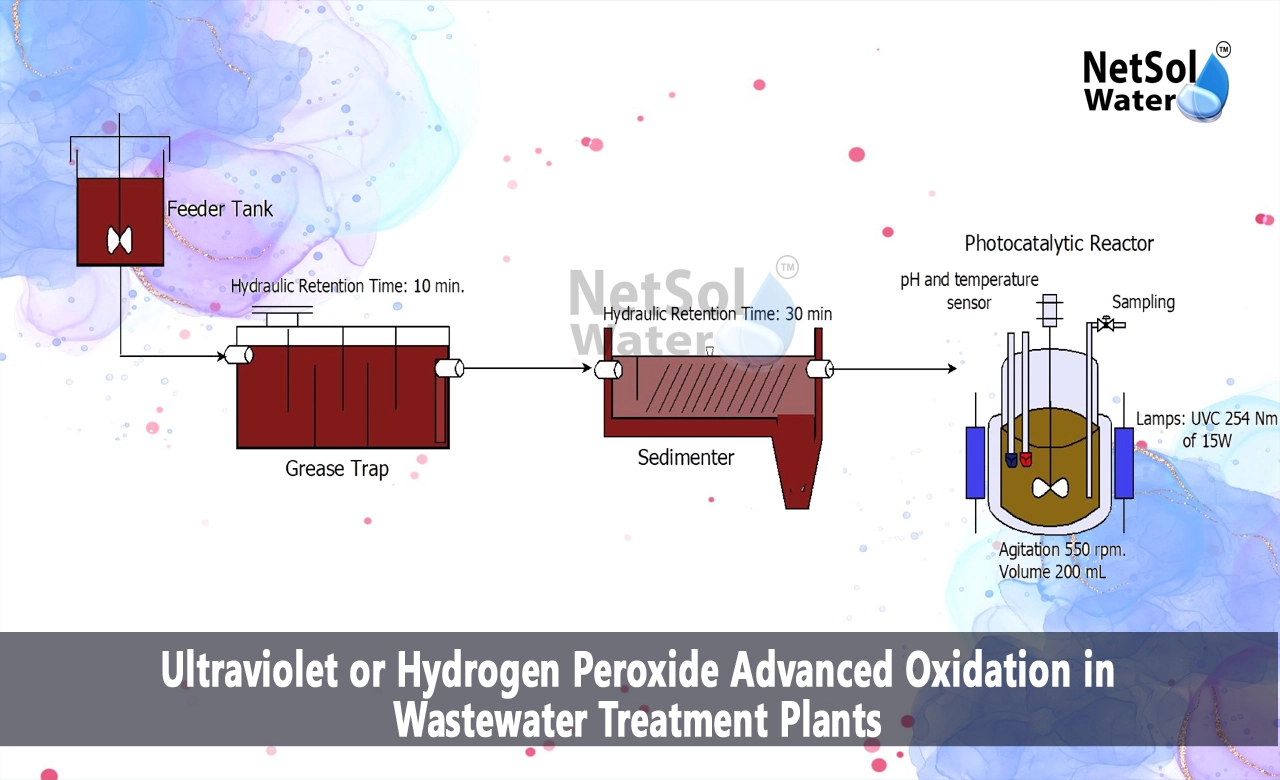

Designing and Running the Reactor: The way the UV/H2O2 reactor is set up, including where the UV lamps are placed and how everything mixes together, can change how well it works. Keeping everything in good shape and watching the operation closely are important for making sure it works well all the time.

Challenges and Future Perspectives

While the UV/H2O2 advanced oxidation process has proven its effectiveness in wastewater treatment, there are still challenges that need to be addressed and opportunities for further improvement:

1. Fouling and Scaling: Over time, the UV lamps and reactor surfaces may experience fouling or scaling due to the deposition of minerals or organic matter, reducing their efficiency. Effective cleaning and maintenance strategies are essential to mitigate these issues.

2. Energy Consumption: Although the UV/H2O2 process is generally energy-efficient, the energy requirements for UV radiation generation and pumping can be significant, especially for large-scale applications. Exploring alternative UV sources or optimizing energy usage is an area of ongoing research.

3. Treatment of Complex Wastewaters: Some industrial wastewaters or wastewaters containing highly recalcitrant organic pollutants may require additional treatment steps or combined approaches with other advanced oxidation processes for effective treatment.

4. Byproduct Formation: While the UV/H2O2 process minimizes the formation of persistent toxic byproducts, the potential for the formation of transient or less harmful byproducts still exists. Further research is needed to understand and mitigate these byproduct formation pathways.

5. Integration with Emerging Technologies: As new technologies and treatment approaches emerge, such as nanotechnology, membrane processes, and photocatalytic systems, there is potential for integrating the UV/H2O2 process with these technologies to create more efficient and sustainable wastewater treatment solutions.

Conclusion

The UV/H2O2 advanced oxidation process has become a go-to method for treating wastewater across many areas. It's great at breaking down lots of different pollutants and making wastewater safe, all while being eco-friendly and not too expensive. That's why it's a popular choice for wastewater treatment plants.

But to make the most of the UV/H2O2 process, we need to pay attention to a few things, like how strong the UV light is, how much hydrogen peroxide we use, adjusting the pH level, and understanding what's in the wastewater. Getting these factors right helps make the treatment super efficient and keeps costs down.

Even though the UV/H2O2 process works well, there are still some challenges to tackle. Things like fouling and scaling, how much energy it uses, dealing with tricky wastewater, making sure we don't make any extra pollutants, and finding ways to use it with new technologies all need more research.

As the need for good ways to treat wastewater grows, the UV/H2O2 process will keep on being important. By using this technology and finding ways to make it even better, wastewater treatment plants can help keep our environment clean and make sure we use water wisely.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.