What is Sludge?

Sludge is the most common by-product of water and wastewater purification, which includes both drinking water and wastewater for disposal.

Processing of sludge is required to reduce:

1: Its size, and thus the cost of later transportation and disposal;

2: The threat it poses to public health, owing to the presence of harmful microorganisms;

3: The odour of it;

4: Putrescence (decomposition of biological materials), and

5: Inherent instability, such as poisonous or otherwise dangerous components seeping.

Properties of Sludge

The properties of the sludge are determined by the quality of the original feedwater as well as the type of unit operation from which the sludge is released.

If the biological treatment is based on the activated sludge process, waste activated sludge (WAS) is produced from the primary sedimentation stage, which produces primary sludge, and the secondary biological treatment stage, which produces waste activated sludge (WAS).

Composition of Sludge

Sludge contains water, dissolved organic and inorganic elements, and suspended particles, regardless of its source. Suspended solids typically account for 25% of the sludge.

The volatile solids (VS) concentration of the organic solids component of the sludge is usually considered to be the most directly helpful. These solids are known as biosolids, and they can be employed as soil fertilizers or have their latent energy converted to heat or a useful fuel (or biofuel).

How many types of Sludge with Sludge Recovery Rates for different STP?

• Primary sludge - The suspended solids settle down by gravity when raw sewage is settled in a primary clarifier. These are extracted from the clarifier's conical floor. This is referred to as main sludge. It will mostly consist of organic and inorganic substances. The organic substances will undergo anaerobic reaction if they are stored. As a result, methane and hydrogen sulphide gases will be produced.

• Secondary sludge - Biological microorganisms develop and multiply when sewage is aerated in aeration tanks. Mixed liquor is the name given to the aerated liquid. It settles in secondary clarifiers, where the microorganisms are separated by gravity. These are extracted from the clarifier's conical floor.

• Return sludge - The microorganisms are seeded with a large amount of the secondary sludge that is returned to the aeration tank. This is referred to as return sludge (RS).

• Wasted sludge - A limited amount of secondary sludge is discarded. This is the difference between secondary sludge and return sludge. On waste sludge, this is known as excess sludge (ES).

• Chemical sludge – It is created when raw sewage/secondary treated sewage is subjected to chemical precipitation.

Separation of Treated Sewage from Treatment Units

Separati?ng the treated sewage from the aerated mixed liquor in treatment units such as MBRs can be accomplished in two ways:

The filtration membranes are submerged in the mixed liquor in one type, and the treated sewage is drawn out as the filtrate in another. There is no secondary sludge or return sludge in this situation. The surplus sludge from the blended liquor is discarded separately.

The membranes are located outside the aeration tank in another form of MBR, and the mixed liquor is separated into treated sewage and secondary sludge.

The primary and extra sludge will be processed further to create entirely inert materials that will not decompose. This is usually accomplished through the therapeutic process. Until practically all creatures are decreased, the organisms themselves serve as a food supply for new life.

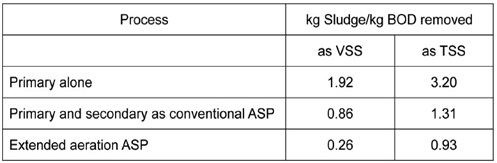

Typical sludge generation values

Factors on which capacity of sludge treatment units depend

The capacity of each sludge treatment unit is dependent on the solids balance of the total sludge treatment plant and is established by considering operating hours, sludge moisture content, retention time, and other factors. The solids balance takes into account the reduction in solids due to gasification, the return load from each plant, and the rise in solids owing to chemical additions, among other things. This is crucial for sludge treatment unit sizing.

In general, a blending tank will be required before further treatment to ensure that the characteristics of the primary and extra sludge are almost uniform when feeding the units.After that, an anaerobic digester is created by putting the thicker sludge through anaerobic digestion to produce Methane. It is referred to as an aerobic digester if it is oxidized. The digested sludge will need to be dewatered in both circumstances. There are many different types of equipment for this, such as centrifuges, filter presses, and natural solar drying beds.

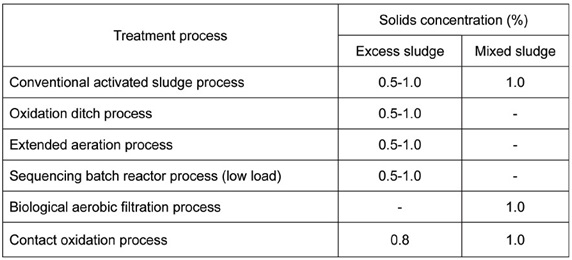

Table showing Solids concentration by different treatment process

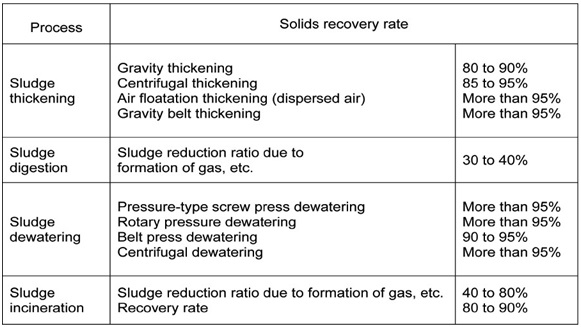

Solids Recovery Rate

Why should you chose us for Wastewater Treatment?

Netsol Water, based in Greater Noida, India, is a well-known industrial and commercial water and wastewater treatment plant manufacturer. We provide experienced treatment solutions for all of your needs.

In accordance with industry standards, our treatment plants employ top quality raw materials and the most up-to-date equipment’s. Our treatment equipment’s are in high demand in the industrial and agricultural industries for a variety of applications.