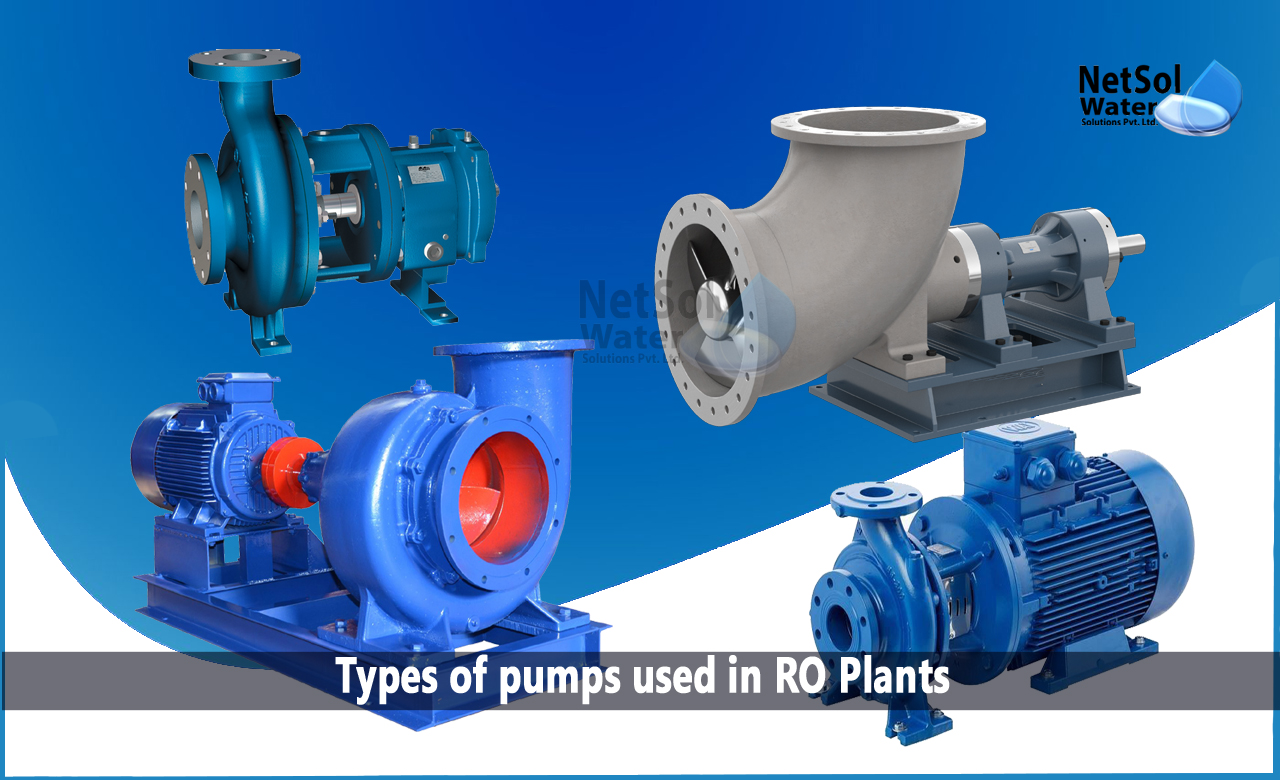

How many types of pumps used in RO Plants?

Reverse osmosis (RO) is a filtration process where pressurized water is passed, through a semi-permeable membrane to generate purified water. Water treatment for drinking purposes, desalination and industrial wastewater treatment, are some of the uses for reverse osmosis.

Water utilities and asset managers are increasingly evaluating their water treatment systems against both sustainability and cost outcomes, with new insights for RO pump selection, in the context of reducing global energy consumption.

Here, we look at the types of pumps used in various industrial applications, and how choosing the proper pump can help achieve goals for cost efficiency and sustainability.

Let’s understand the types of pumps used in RO Plants!

· Positive Displacement Pumps

A positive-displacement pump moves a fluid by forcing (displacing) the volume, which is trapped into the discharge pipe.

In some positive-displacement pumps, the suction side cavity expands while the discharge side cavity contracts. As the cavity on the suction side expands, liquid enters the pump, and as the cavity contracts, liquid exits the pump. Throughout every cycle of operation, the volume remains constant.

Because, it lacks a shutdown head like centrifugal pumps do, a positive-displacement pump cannot run against a closed valve on the discharge side of the pump. The pressure in the discharge line builds up as a result of a positive-displacement pump, producing flow in opposition to a closed discharge valve, until the line bursts the pump sustains significant damage, or both.

Types of pos?itive displacement pumps

According to the method utilized to transport the fluid, a positive-displacement pump can be further divided into the following categories:

1: Internal or external gear pumps, screw pumps, lobe pumps, shuttle blocks, flexible vane or sliding vane, circumferential pistons, flexible impellers, helical twisted roots, or liquid-ring pumps are examples of rotary-type positive displacement pumps.

2: Positive displacement reciprocating pumps: piston pumps, plunger pumps, or diaphragm pumps.

3: Rope pumps and chain pumps are linear-type positive displacement pumps.

· Centrifugal Pumps

A radial flow pump is another name for this type of device. The centrifugal fan, which is frequently used to implement a vacuum cleaner, is an example of a device where the fluid enters along the axis or center, is accelerated by the impeller, and then exits at right angles to the shaft (radially).

Vortex pumps are yet another variety of radial-flow pump. They contain liquid that circulates tangentially around the working wheel. Multiple whirls, which are produced by the impeller in the working channel of the pump, are used to convert the mechanical energy of the motor into the potential energy of flow.

In contrast to axial or mixed-flow pumps, radial-flow pumps typically operate at higher pressures and lower flow rates.

· Axial Flow Pumps

To move fluid axially, it is pushed either outward or inward. They function at far lower pressures and higher flow rates, than centrifugal (radial-flow) pumps. It is impossible to accelerate axial-flow pumps without taking extra care.

If the flow rate is low, the pipe's high starting torque and overall head increase, would force the starting torque to change into an acceleration function for the entire mass of liquid in the pipe system. Accelerate the pump gently if there is a lot of fluid in the system.

· Mixed Flow Pumps

A compromise between axial and radial-flow pumps is achieved by mixed-flow pumps. Between 0 and 90 degrees from the axial direction, the fluid exits the impeller having undergone, both radial acceleration and lift.

Due to this, mixed-flow pumps deliver higher discharges than radial-flow pumps, while operating at higher pressures than axial-flow pumps. In respect to radial and mixed flow, the flow's departure angle determines the pressure head-discharge characteristic.

Conclusion

Reverse osmosis pumps are distinguished by their capacity to deliver high constant pressure and a sizable flow. Specialized pumps are required for the passage of pressurized raw water via a membrane.

How can we assist?

Netsol Water provides multistage RO Plants with centrifugal pumps made of stainless steel, which can handle a variety of harsh liquids.

These are small, simple to install, and have a space-saving design. They produce less noise and require little upkeep. For further information, contact us at +91 9650608473 or email at enquiry@netsolwater.com