How many types of Grit Chamber?

Grit chamber is a long rectangular or circular tank in the primary sewage treatment plant or wastewater treatment plant that is designed to remove grit, or other heavy solids that have specific gravity greater than the organic solids in wastewater. Grit chamber is used in primary treatment of wastewater and to remove suspended inorganic particles such as sandy and gritty matter.

Types of grit chamber

Generally there are three types of grit chambers:

a) Horizontal-flow grit chamber

b) Aerated Grit chamber

c) Vortex type grit chambers.

All of these designs allow heavy particles to settle out, while lighter organic particles remain in suspension.

Depending upon various factors such as the type and amount of grit to be handled, head loss requirements, area requirements, topography and economic considerations with respect to both capital and operating costs, grit chambers are divided into-

1: Mechanically Cleaned

2: Manually Cleaned

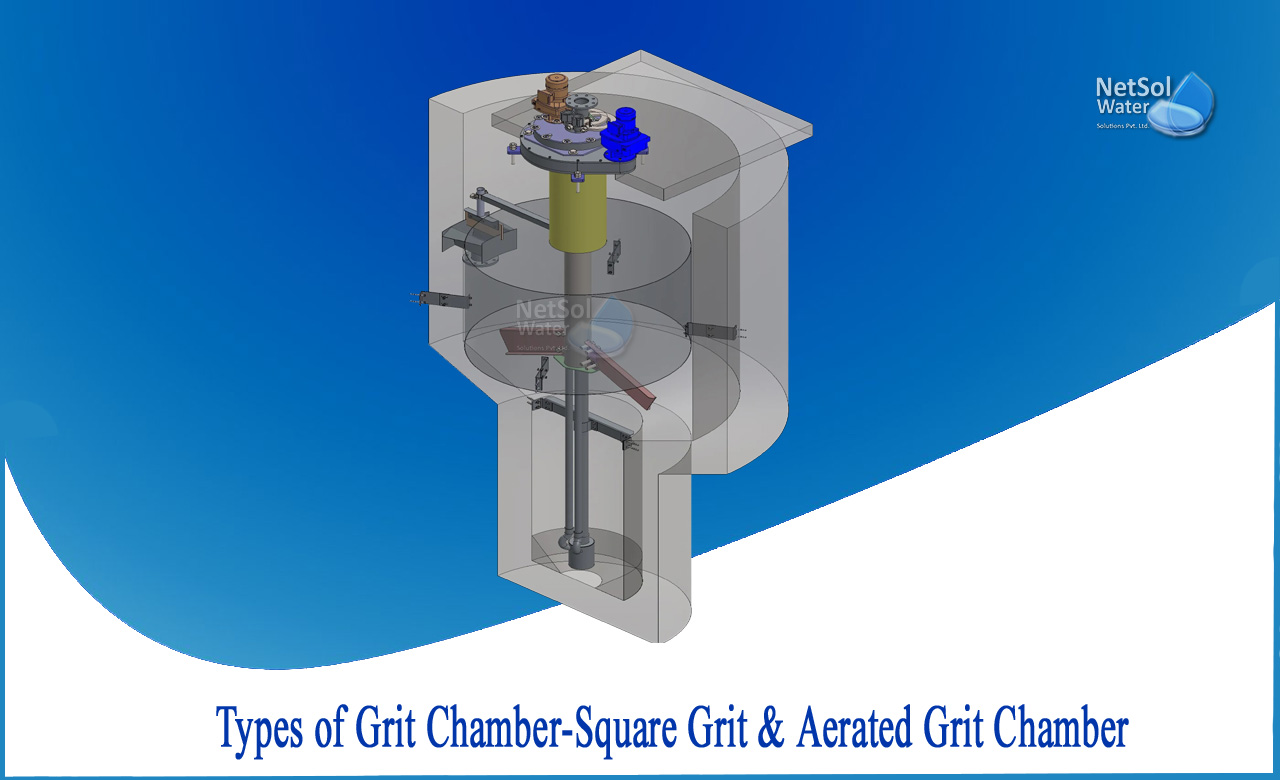

But, let us talk more about Aerated and Square Grit Chambers!

>Aerated Grit Chamber

Aerated grit removal system removes grit by forcing water into the grit chamber that has air pumped into it. The air causes the heavier particles to be thrown out of the water or wastewater streamline while lighter organic particles remain suspended. Excessive abrasion of grit handling equipment and necessity of separate grit washer can be eliminated by using aerated grit chamber.

It is typically designed for detention time of 3 minutes at maximum flow. The diffusers are located at a distance of about 0.45 to 0.6 m from the bottom. The size of particles removed depends upon agitation velocity. The air flow rate can be adjusted and 100% grit removal can be achieved.

The mechanism followed in aerated grit chambers

Wastewater travels in helical path across the bottom of the tank at maximum flow. Wastewater is allowed to enter in the direction of roll in the grit chamber. The volume expansion due to introduction of air must be considered in design. The aerated grit chambers are equipped with grit removal buckets. Chain and bucket conveyers are also used. Two grit chambers kept parallel can also be used to facilitate maintenance.

DESIGN DETAILS FOR AERATED GRIT CHAMBER

|

Depth Length Width Width to depth ratio Detention time at peak flow Air supply m3/min.m of length |

2 to 5 m 7.5 to 20 m 2.5 to 7.0 m 1:1 to 5:1 2 to 5 min 0.15 to 0.45 |

>Square Grit Chamber

The rectangular grit chamber faces the disadvantage of sedimentation of organic matter along with grit particles so requires external washing of the grit before disposal. This problem can be reduced by the provision of square shape of the grit chamber instead of long rectangular channel. Square shape of chamber will facilitate compact design of sewage treatment plant. Hence nowadays square grit chambers are used.

The distribution of flow may not be uniform due to non-ideal plug flow conditions in these grit chambers. Hence the removal of grit continuously is considered essential. These are designed on the basis ofoverflow rates that depends on the particle size and temperature of wastewater.

Minimum two grit chambers are required to facilitate maintenance of the raking mechanism.

The grit deposited at the bottom of the chamber is raked out by rotating mechanism to a sump outside the tank, from which it is moved up by an inclined reciprocating screw pump mechanism.Organic solids are separated from grit as it passes the inclined conveyer andflows back into the basin. The cleaned washed grit is obtained, compared to the grit obtained from separate grit washers.

What can Netsol Water offer you?

Netsol Water is one of the leading water and wastewater treatment company in India with services in the field of WTP manufacturing, WWTP manufacturing, STP manufacturing, ETP manufacturing, among other services. The company designs and manufactures machines and is dedicated to practical solutions that spur business growth and simultaneously preserves world’s most precious resource- WATER!

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.