How many Types of Aerators used in Wastewater treatment?

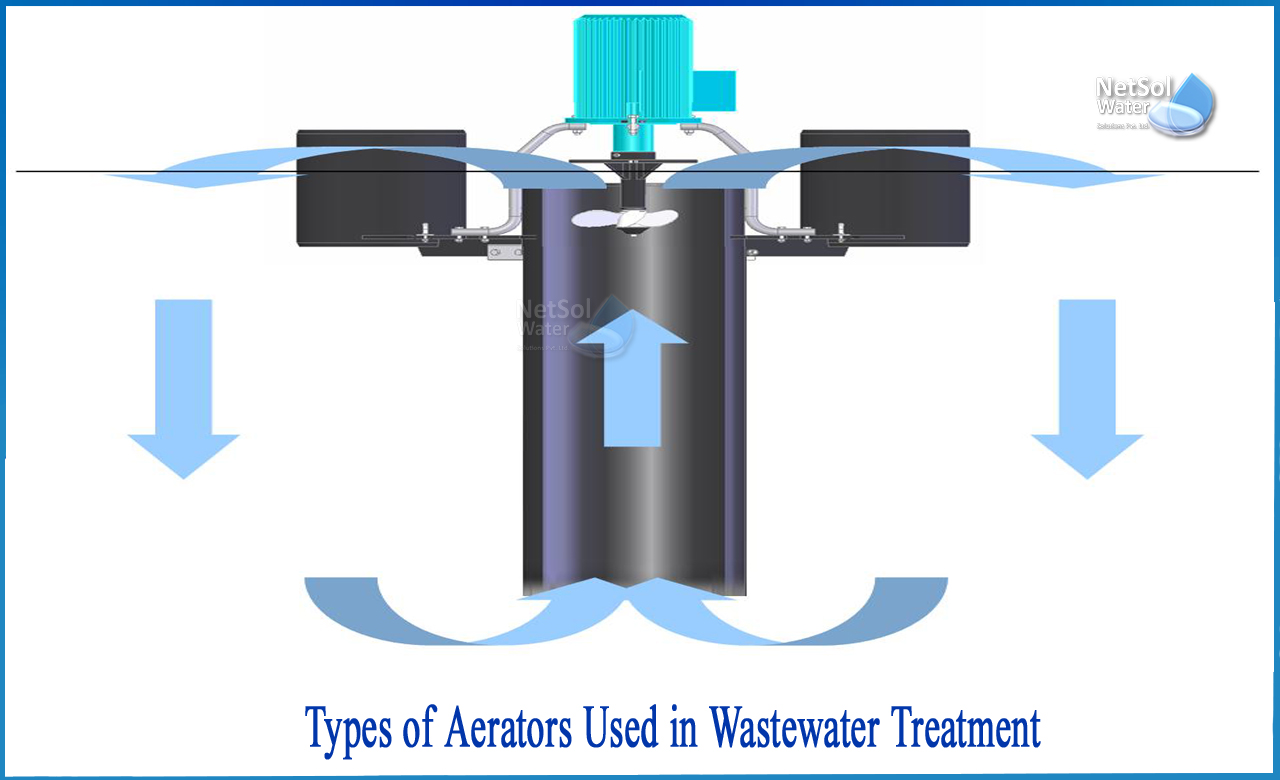

Aeration of wastewater happens when air is given directly to the wastewater, allowing for aerobic biodegradation of any contaminants present. Aeration is an important part of the wastewater treatment process.

The fundamental advantage of aeration is that, it is a natural way to remove contaminants from wastewater. When used in large quantities, the chemicals employed in alternative treatment techniques can be dangerous. The aeration technique, on the other hand, uses microorganisms that already reside in the wastewater to decompose the toxins.

Aeration is significant because, when compared to other possibilities, it is extremely effective, economically viable, and environmentally friendly. The aeration process provides oxygen to bacteria, which aids in the treatment and stability of wastewater. To complete the bio-degradation process, the bacteria require oxygen. When the bacteria is given enough oxygen, it will break down all of the carbon-based organic materials into water and carbon dioxide.

1: Aerator with a Packed-Tower

A packed-tower aerator is a system that comprises solely of packing material in the form of a tower.

Because these towels may reach up to 10-feet tall, you'll need plenty of room in your building if you wish to employ this aeration system. The packing material contained within a packed tower can range in size from 1/2 inch to three inches and can be made up of tiny pieces of plastic or ceramic. While several materials can be utilized with this sort of aeration system, there is no advantage to utilizing one over another.

However, it has been shown that smaller bits of material allow for greater efficiency despite raising energy expenditures.When this method is used, wastewater will fall from the top of the tower as air is pumped upwards into the water. The impurities will pass from the water to the air before being vented outdoors, making this a fairly simple form of aeration system.

The following are the primary advantages of employing a packed tower system:

1: The system is quite simple to keep up with.

2: By changing between different packing material sizes, you may directly manage the system's efficiency.

3: These systems are considered to be extremely successful in removing pollutants.

4: This system is capable of removing volatile pollutants from water more effectively than other systems.

2: Diffused bubble aerator

A diffused-bubble aerator is the most common form of aeration system, consisting of multiple chambers as well as a diffuser through which air is blown.

Small bubbles will be created by the diffuser and will pass through each chamber. The bubbles transport the chemicals and impurities that you're attempting to remove. The pollutants will be released into the outside air once they have passed through the whole vent system. A diffused-bubble aerator with a greater number of chambers is a more efficient system. A few of these aerators are equipped with a switch that will sound an alert if the chambers are about to overflow. While there are numerous varieties of diffused-bubble aerators, they all work in the same way.

The key advantages of utilizing a diffused-bubble aerator for wastewater treatment are as follows:

1: Can be utilized efficiently with deep tanks

2: Have a versatile design

3: Outperform other forms of aeration systems in terms of efficiency

4: The blower is simple to use

5: Requires little upkeep and has a low environmental effect

6: Longevity is provided by its high durability

7: Consistent performance in adverse weather conditions

3: An Aerator Spray

A spray aerator is a technique that removes tiny amounts of volatile contaminants. When employing this method, water will enter at the very top of the system before materializing as a very fine mist from spray heads. The water treated by a spray aerator is collected in a vented tank located beneath the spray heads. The impurities that have been gathered will be discharged and vented outdoors.

The advantages of employing a spray aerator for wastewater treatment include the following:

1: This sort of system is particularly good at removing volatile pollutants such as radon.

2: It is a very simple system that is simple to maintain.

3: It aids in the oxidation of manganese and iron.

4: Significantly increases the amount of dissolved oxygen in the water.

5: Is quite inexpensive in comparison to other aeration systems.

6: Doesn't often take up a lot of room.

The upkeep of all three aerators-

When using one of the three types of aeration systems available, it is also vital to ensure that the space is well ventilated. Regular cleaning of the trays and tanks in the aeration system is also essential to avoid the growth of rust, algae, and sulphur.

If you follow these maintenance recommendations, you should be able to keep your aeration system in excellent operating order, prolonging its lifespan and saving money on repairs.

Conclusion

Aeration of wastewater occurs when air is directly introduced into the wastewater, allowing for aerobic biodegradation of any pollutants present. Aeration is a critical step in the wastewater treatment process.

How can Netsol Water help?

Netsol Water is a significant water and wastewater treatment firm in India, offering WTP, WWTP, STP, ETP and RO Plant manufacture,among other services. We are committed to providing our valued customers with hands-on service, expert counselling, and training. Every environmental problem and its management have a solution in us.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.