How to treat and dispose of Screening and Grit?

A screen is a device with uniformly sized apertures that is used to remove larger suspended or floating debris from sewage or other wastewaters. Prior to pumping stations, meters, and all treatment activities, screens are utilized as a preliminary step.

Screening is an important stage in sewage treatment because it removes debris that may otherwise damage equipment, interfere with the proper operation of treatment units or equipment’s, or generate unfavorable shoreline conditions if sewage is discharged into the sea.After screening, the sewage is devoid of floating items such as sachets, plastic sheet parts, leaves, fibers, and rages.

Elements of screening

Parallel bars, rods, gratings, wire meshes, or perforated plates are examples of screening elements. According to the guidelines, screens should be provided in three stages:

Coarse, medium, and fine.

Methods of disposal of screenings

Methods of disposal of screens could be burial or composting. The screenings should not be left open or transposed in uncovered conveyors as it would attract flies and insects. Conveyors should be kept as short as possible for sanitary reasons when used.

Burial in trenches is practiced particularly in small installations. Where adequate land for burial of screens is not available within a reasonable distance from the treatment plant, screenings shall be transported and mixed with town refuse for production of compost.When land becomes available, screens can be separated to eliminate non-biodegradable components before being blended with grit and compacted.The plastics that have been removed will be disposed of in municipal solid refuse.

Grit

Grit has a greater hydraulic subsidence value than organic materials because it is non-putrescible. The grit's specific gravity is typically between 2.4 and 2.65.

Composition of Grit

Grit in sewage is made up of gritty sand particles, ash and clinkers, egg shells, bone chips, and other inorganic elements.

Quality and quantity of grit varies depending upon following factors:

(1) Types of street surfaces encountered;

(2) Relative areas served;

(3) Climatic conditions;

(4) Types of inlets and catch basins;

(5) Amount of storm water diverted from combined sewers at overflow points

What is Grit Removal?

The removal of grit is important to protect the moving mechanical equipment and pump components from abrasion and abnormal wear and tear. The frequency of cleaning digesters and settling tanks is also reduced when grit is removed.

In the case of mechanized grit chambers, screens or comminuting devices should be provided before of the grit chambers to decrease the influence of rags and other big floating objects on the mechanical equipment. However, sometimes sewers are installed at such a depth that grit chambers upstream of pumping units are undesirable or uneconomical.Pumps are preceded by a bar screen, which is followed by grit chambers and other components. As a result, following grit removal, the sewage must be as free of grit particles as feasible.The grit removal devices should be on standby at all times.

Clearing of the Grit

Clearing of the grit manually needs to be avoided.Mechanical clearing is recommended, and these are equipped with mechanical equipment for not only grit collection but also grit washing, and they can be used on a continuous or intermittent basis. Scraper blades or ploughs moved by a motor gather grit that has collected on the grit chamber floor. Several systems, such as bucket elevators, jet pumps, screws, and air lift, are used to raise the grit to the ground level.

Grit washing mechanisms come in a variety of configurations, the most of which are agitation systems that use either water or air to provide washing action. In the intermittently operated kind (usually once or twice a day), adequate storage capacity to retain the grit between grit elevation intervals should be supplied.

What can we offer?

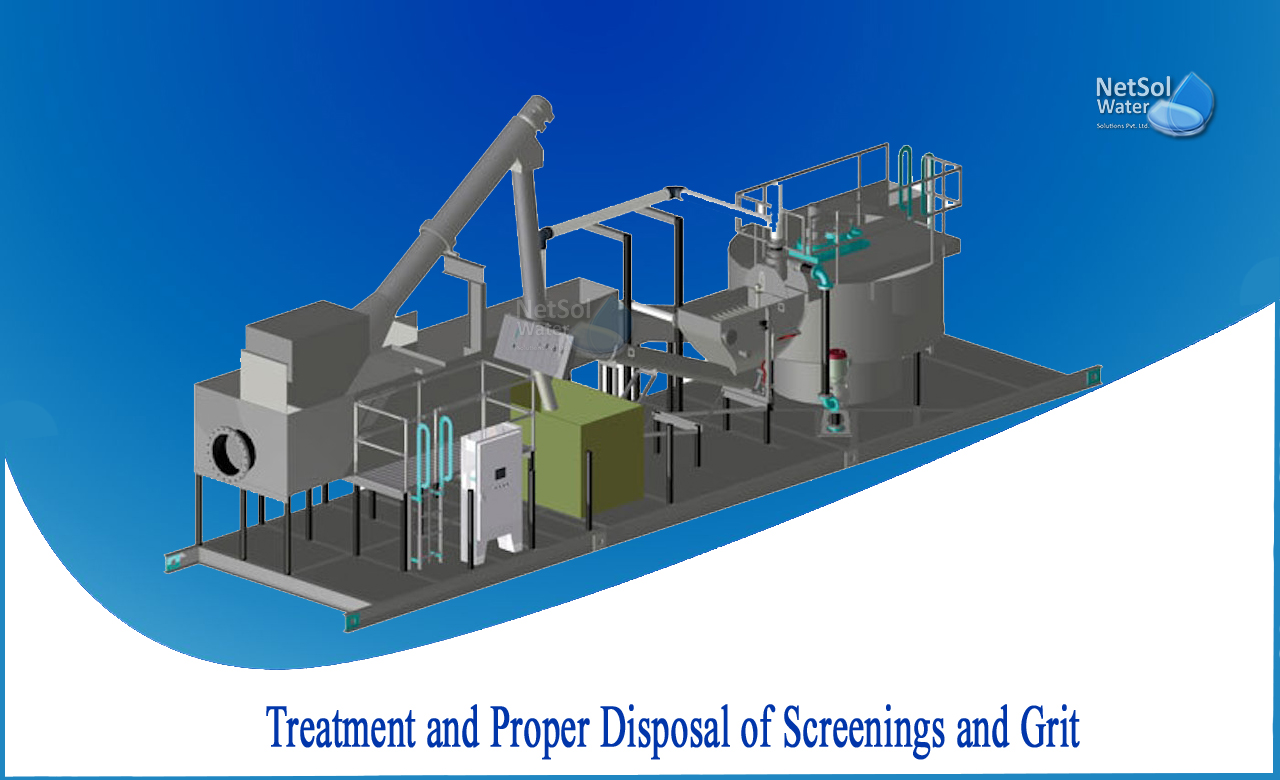

Netsol Water is one of India's major Water and Wastewater management company, specialized in the design, manufacture, and delivery of custom-made treatment systems, industrial machinery, and luxury amenities for the water and wastewater industry. We can customize WTPs/WWTPs that will cater to all our needs and at the same time effectively treat different types of wastewater.

If you need any advice or assistance on selecting the best water and wastewater treatment unit,

Call us on +91-965-060-8473;