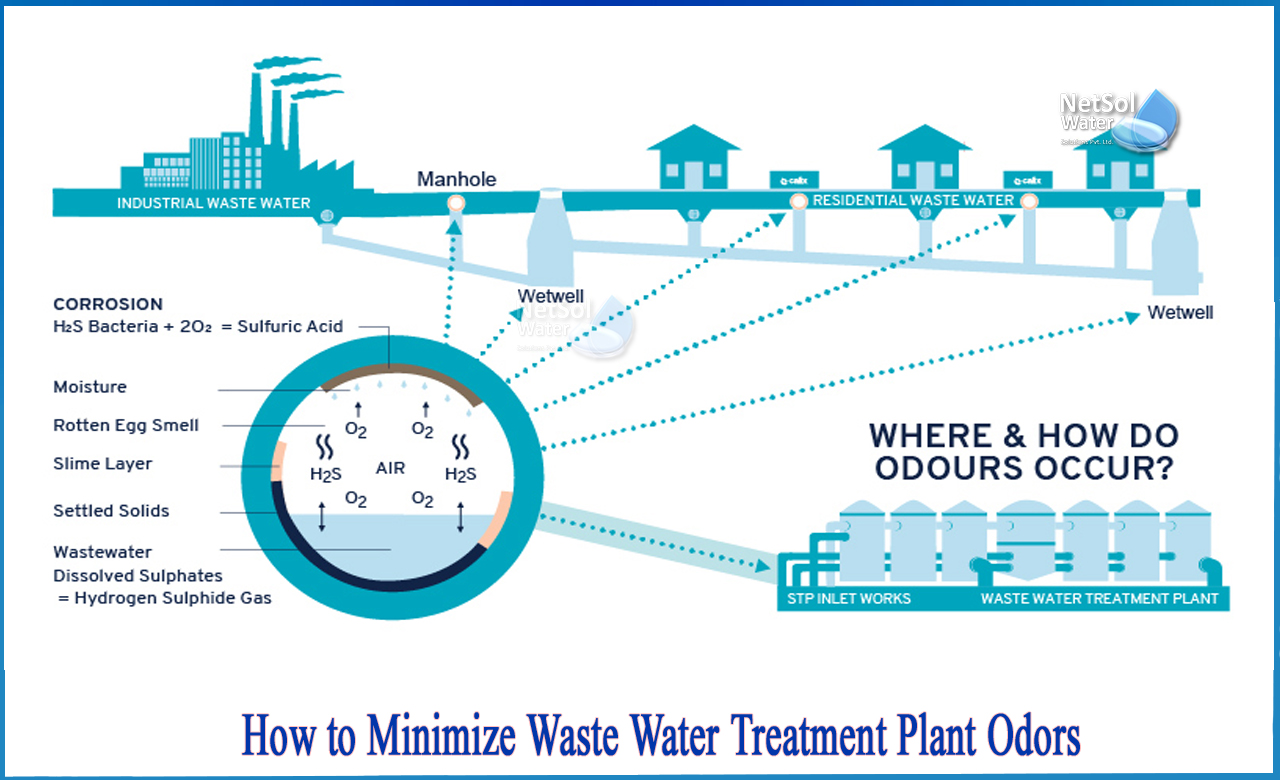

How to minimize waste water treatment plant odors?

In today's wastewater treatment (WWT) world, odor control has progressed from an afterthought to a primary design consideration for the majority of collection and treatment facilities. As development encroaches on our facilities and new neighbors become less tolerant of noxious odors, wastewater professionals have realized the importance of prioritizing odor control in the design and operation of collection and treatment facilities. The number of odor control technologies available in the market has increased in tandem with the importance of odor control.

Some of the technologies that are designed to reduce WWT odors are as follows:

1-Vapor-phase technologies

Point sources of odor problems are ventilated using vapor-phase technologies (wet wells, headworks, etc.). The ventilation system is designed to maintain a negative pressure on the area at all times for air treatment. This prevents odorous air from "leaking" from vents, mainways, access hatches, or other areas. The discharge from the ventilation system must be treated because it is the only way for odorous air to escape. Vapor-phase systems are extremely effective at preventing fugitive emissions from ventilated sources, as well as the odor issues that come with them.When large amounts of air are ventilated, vapor-phase systems can also provide adequate ventilation for occupancy and/or reduce contaminant concentrations to levels that do not pose safety or corrosion hazards.

2-Wet air scrubbing

Wet air scrubbing is the most adaptable and dependable technology for odour control in vapor-phase wastewater. This technology can treat almost any water-soluble contaminant. Wet scrubbing is very effective for removing ammonia as well as hydrogen sulphide and "organic" odors. The odour contaminants in a wet air scrubber are solubilized from the vapor phase into an aqueous chemical solution. The removal mechanism is entirely chemical and, unlike biological processes, is not susceptible to disruption. The use of a multi-stage scrubber allows for the use of a different chemical solution in each stage, allowing for the efficient use of chemicals and the treatment of a wide range of contaminants.

The use of chemicals and chemical reactions provides one of the most significant advantages of wet scrubbing systems in terms of dependability and flexibility. Minimizing chemical use and cost while maintaining complete, flexible, and reliable treatment is a major challenge in the design and operation of wet air scrubbers. The multi-stage scrubbing system is one design used to reduce chemical use. As previously stated, the most common contaminant in raw wastewater applications is hydrogen sulphide, but other organic odorous compounds are also commonly present. A solution of sodium hydroxide can be used to dissolve hydrogen sulphide.

3-Liquid redox technology

Liquid redox technology has a relatively long history, but is not widely used in the market. The majority of liquid redox processes are used in the petrochemical and natural gas industries and are generally regarded as too complex and expensive for these applications. Liquid redox units remove hydrogen sulphide from a gas stream and catalytically convert it to solid, elemental Sulphur using a chelated metal dissolved in water. The metal, which is kept in solution by organic chelating agents, acts as a catalyst, accelerating the naturally occurring reaction.

Many metals can perform these functions, iron (Fe) is the most commonly used commercially because it is inexpensive and non-toxic.Where these processes have seen increased demand is in the treatment of anaerobic biogas, where higher levels of hydrogen sulphide and the presence of carbon dioxide cause wet scrubbers' lower capital costs to be offset by their much higher operating chemical costs.

4-Bio-filtration

Biofiltration technology can be used to treat a wide range of water-soluble biodegradable contaminants. Odor contaminants are solubilized from the vapor phase into the aqueous phase in a biofilter on the surface of an organic medium such as compost, mulch, or peat. The compounds are then degraded by the bacterial population present in this medium. Sulfur-based odor compounds such as hydrogen sulphide, organic sulphides, and mercaptans are extremely effective at being removed by biofilters. In general, biofilters are ineffective at removing nitrogen-based compounds such as ammonia and amines.

Two major challenges in biofiltration systems are media stability and control of the biofiltration process. The bed settles and compacts as a result, increasing the head loss through the filter. This reduces airflow and, in most cases, results in fugitive odor emissions from the source. Controlling the biofiltration process is also an important consideration. The biological population within the filter, like any other organism, is vulnerable to disruptions. If the media is subjected to significant changes in environmental conditions, the bacteria population may be disrupted, resulting in odor breakthroughs.

For more information, contact Netsol Water.