Water quality has become increasingly important in recent years, owing to limited water resources and rapid industrialization. Ammonia is a common pollutant found in industrial and agricultural effluents. It is used as a bleaching agent in the chemical industry, as well as in the manufacture of fertilizers, plastics, and explosives.

Presence of Ammonia in effluents

Ammonia exists in equilibrium with ammonium ions in effluents. The concentration of ammonia gas rises as the pH and temperature rise. Most ammonia exists as dissolved ammonium ions at neutral pH, but as the pH rises to 12, both ammonium ions and gaseous ammonia coexist in the effluent. Ammonia in effluents is generally estimated using Nessler's method and is expressed as Ammonical Nitrogen (NH3-N) in ppm.

Is Ammonia an essential macronutrient?

Although, ammonia is a naturally occurring element and an important macronutrient for plant growth, it is toxic to aquatic life at higher concentrations. The presence of gaseous Ammonia in effluent can cause utility line corrosion, as well as the release of foul pungent odours in the surrounding area.

As a result, regulatory bodies around the world have expressed concern about the dangers of abnormal discharge of ammonia-rich effluents. As a result, addressing this issue before an ecological crisis occurs is critical.

How to treat Ammonia in Effluents?

· Ammonia Stripping

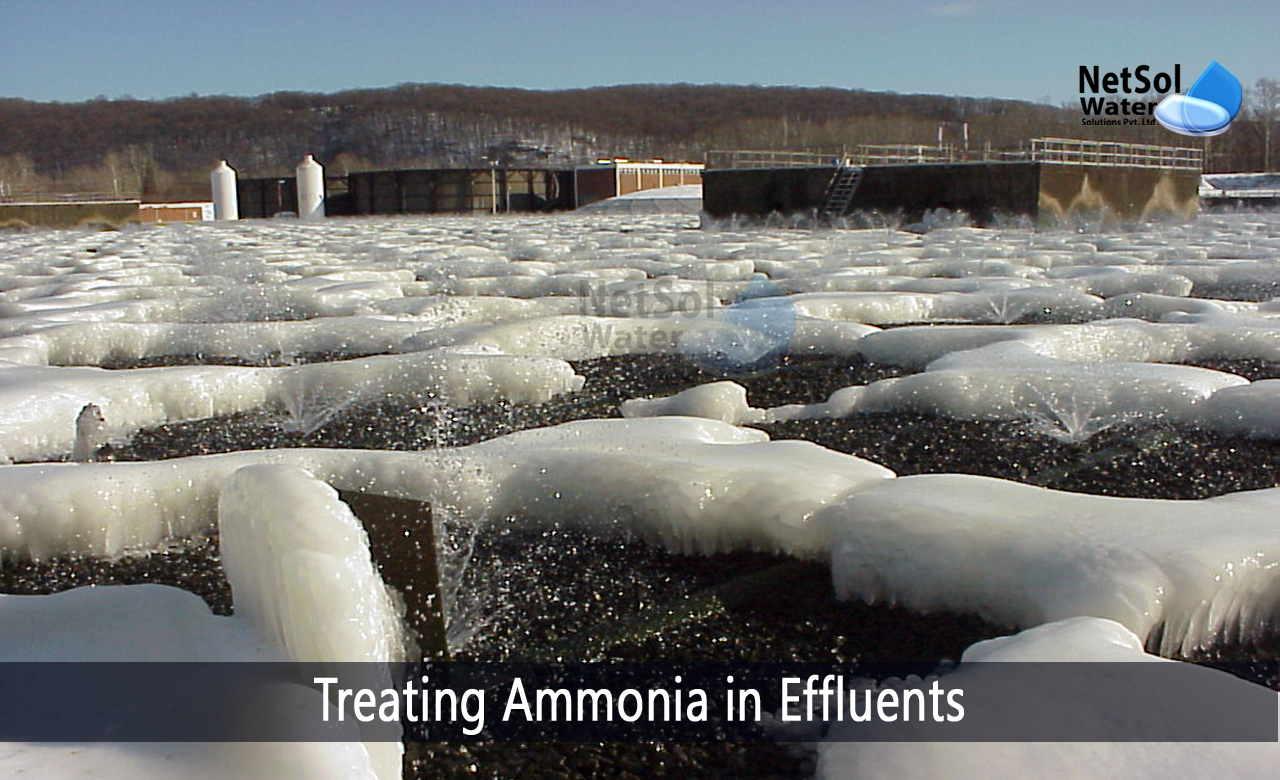

A modified cooling tower is used to remove ammonia from effluent. The pH of the effluent is kept above 9, and it is passed through a sparger-equipped packed column. The column is constantly sparged with high-pressure air, and the temperature is kept at 120°F.

The generated air current transports the gaseous ammonia out of the effluent system. The process efficiency is highly dependent on system temperature, and necessitates significant economic expenditure for utility maintenance.

· Oxidizing Agents

Ammonia removal via oxidizing agent treatment is also included in settling tanks following secondary treatments. One of the most common reagents used to oxidize ammonia in effluents is sodium hypochlorite. However, due to the inherent toxicity of these reagents, strict application monitoring is required.

· Ion exchange Chromatography

The effluent is passed through zeolite packed columns in ion exchange chromatography for ammonia removal. Clinoptilolite (a type of Zeolite) has a high affinity for NH4+ ions and can scavenge all traces of the pollutant, in the effluent.

The recovered product is ammonium sulphate, which can be used as a chemical fertilizer, and the treated water can be recycled for agricultural irrigation. The only disadvantage of this process is the high cost of column regeneration, and disposal of residual wastes generated.

· Microbial Augmentation

Aerobic (Nitrifying and Denitrifying bacteria) and anaerobic ammonia removal in effluents (Anammox organisms)

1: Aerobic (Nitrifying and Denitrifying bacteria)

Two groups of bacteria convert ammonia/ammonium ions (NH4+) to atmospheric nitrogen, in aerobic processes. The first group of bacteria is known as Nitrifying Bacteria and includes Nitrosomonas spp., Nitrococcus spp., and others. These bacteria use advanced enzyme machinery to convert dissolved ammonium ions to nitrites (NO2), which are then converted to nitrates (NO3).

The second group of Bacteria is known as Denitrifying Bacteria and includes bacterial species, such as Micrococcus spp., Pseudomonas spp., and others. Under low oxygen conditions these bacteria convert nitrates to atmospheric nitrogen. As a result of the combined action of both nitrifying and denitrifying bacteria, ammonia is completely removed from the effluent.

2: Anaerobic ammonia oxidation

Under anaerobic conditions, ammonical nitrogen is converted into atmospheric nitrogen. Because, these bacteria grow slowly, with a generation time of 10 days, they are typically cultured in a sequential batch reactor. Kueneniastuttgartiensis and Anammoxoglobus spp. are two common Anammox bacteria.

As a result, microbial augmentation improves the efficiency of ammonia removal in effluents. Microbial growth utilizes indigenous organic matter for biomass development, providing a dual benefit of lowering COD and Ammonical nitrogen content in effluent.

What do we offer?

To summarize, there are numerous methods for resolving the problem of ammonia in the effluent, but microbial augmentation is the best for obtaining results that can withstand the demands of the hour.

This is where Netsol Water comes in, trying to protect the environment and tackling ammonia in effluents.

We are dedicated to providing exceptional services to our customers, and to supplying water to those in needs. We recognize the importance of water in the present and future, and we treat it with care.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.