The science of heat transfer examines how quickly hot and cold bodies, or source and receiver, exchange heat.

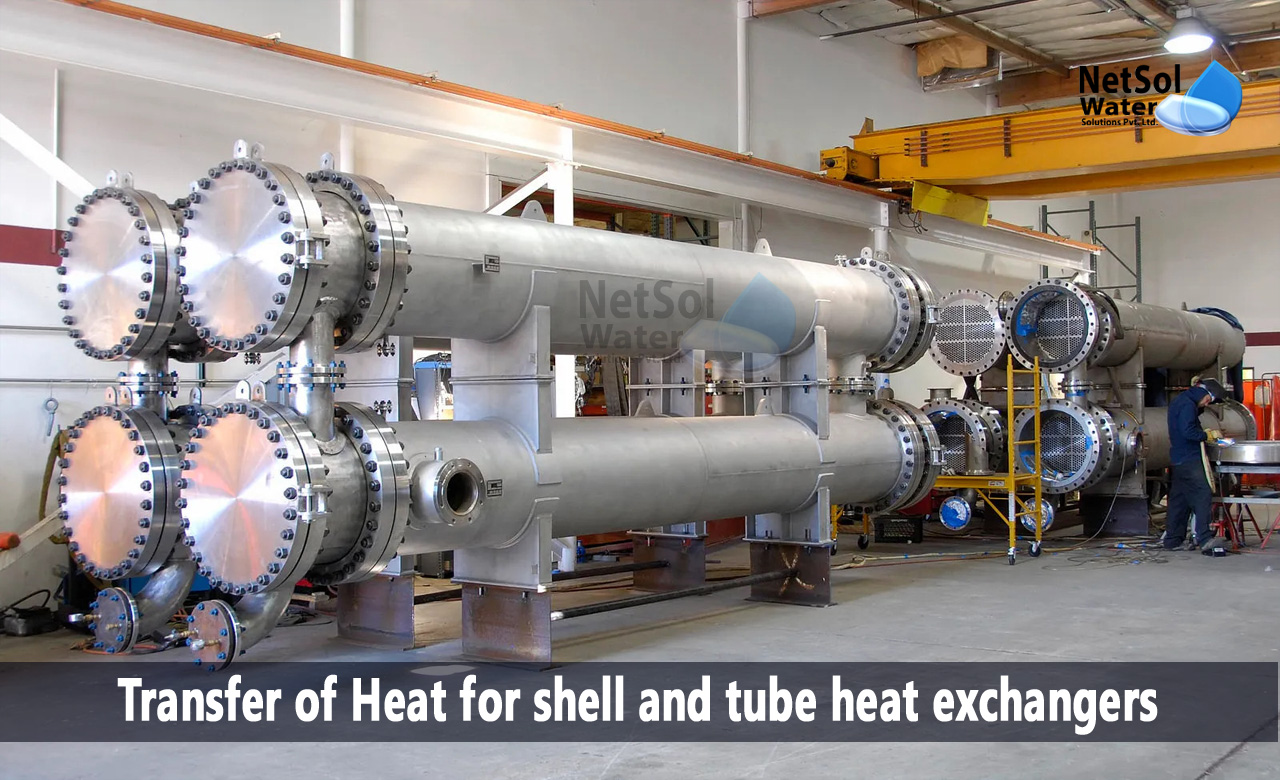

What is Transfer of Heat for shell and tube heat exchangers?

The three components combine to form the overall heat transfer coefficient (OHTC), in shell and tube type heat exchanges. They are metal wall resistance, shell side heating media film coefficient, and tube interior liquid media film coefficient.

Heat can go from a source to a receiver in many ways. Despite, the fact that most engineering applications combine two or three elements, these are examples of conduction, convection and radiation.

· Conduction

Conduction is the term used to describe the passage of heat through a body, by the momentum of individual atoms or molecules without mixing, i.e. Conduction is the flow of heat through fixed objects.

· Convection

Convection is the process through which heat moves when warm areas and cool areas of the same material, actually mingle, i.e. due to large fluid mass movements, heat transfer through convection happens in a fluid, with a different position.

Free convection and forced convection are two subcategories of convection.

1: The process is referred to as forced convection if the fluid is pushed to flow by an outside force, such as a fan or pump.

2: Free convection or natural convection is the process where the fluid is created by density changes, which are brought about by temperature variances present in the fluid mass.

Fluids almost never flow through pure conduction without any convection. The real method of energy transfer from one fluid particle or molecule to another is still conduction, but the fluid's own movement can sometimes be used to port energy, from one location in space to another.

· Radiation

Radiation is the name given to the electromagnetic wave-based transmission, of energy over space.

According to Fouries' law, the area, temperature, and inversionally proportionate length of the flow path, are all related to the rate of heat flow through a homogeneous material.

Consider a straightforward scenario to help you understand the overall heat transfer coefficient.

Consider heat transfer through a pipe wall that involves forced convection of varying intensities, on both sides of the pipe. A hot liquid that is moving outside deposits heat, and a cool liquid that is flowing inside, absorbs heat.

By determining the temperature differential between the pipe surface and the liquid's average temperature, either resistance can be determined independently.The sensible heat change in fluid throughout the pipe's length, where the heat transfer takes place, can be used to calculate the heat transfer.

Why should you select Netsol Water as the manufacturer of your water treatment systems?

We are the leading producer and supplier of commercial RO Plants, industrial RO systems, water softeners, etc., in India. Our system is exceptionally reliable and cost-effective for use in an industrial environment. We work with each of our clients to give high-quality filtration systems at affordable pricing, since we are aware that you need the best systems available, at fair and competitive prices.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.