How to remove Oil & Grease by Waste Water Treatment?

Oil and grease removal is a simple and inexpensive process. Process industries should take the lead in addressing these issues so that they are prepared when the law goes into effect. Furthermore, if they design their system in such a way that the water can be recycled, they can use new laws to save money and reduce public concern about the discharge of contaminated wastewater.

Effective O&G removal necessitates an understanding of emulsions and mechanical versus chemical separation. In addition, the operator must be able to break emulsions and test effective treatment methods in the laboratory. He must then understand how to economically remove the now mechanically emulsified oil (i.e., how to effectively coalesce the oil droplets and reduce the O&G content to undetectable levels) so that wastewater recycling is feasible. This requires knowledge of post-polishing techniques, particularly the use of organically modified clays (organoclays). Organoclays remove oil and grease from water at a rate seven times faster than activated carbon.

.png)

Presence of oil:

Oil can be found in wastewater in a variety of forms, including free oil and grease (FOG), oil wet solids, chemically emulsified oil, mechanically emulsified oil, and dissolved oil.

>Free oil and grease

Under calm conditions, free oil rises rapidly to the surface of the water tank, 150 microns is the size of the droplet. This oil can be separated by filtration using an overflow weir and a skimmer. The traces can be transmitted by passing the wastewater through an adsorber tank filled with organoclay (such as a carbon tank).

>Emulsified oil

The size of these oil droplets ranges from 20 to 150 microns. Electrical charges and other forces that result in the coating of suspended solids stabilise mechanically emulsified oil. Such oils mix with water as a result of shear caused by wastewater passing through a pump, splashing into a tank, or anything else that breaks up and disperses larger oil droplets.

>Oil wet solids

Oil that adheres to sediments and other particulate matter, such as metal chafing’s found in industrial wastewater, fall into this category. Sand filters, bag filters, flocculants, and oil/water separators are used to remove such oil solids. These processes are followed by organoclay polishing.

>Chemically emulsified oil

When emulsifiers such as surfactants or soaps are present, oil is chemically emulsified in water. Surfactants contain hydrocarbon chains. The most basic are sodium laurel sulphate and stearic acid, both of which have hydrophilic (water-loving) and lipophilic (oil-loving) ends. The lipophilic end of the molecule enters the oil droplet, while the hydrophilic end remains in the water. Because this generates a charge on the otherwise neutral oil droplet, the droplets repel and disperse. This is referred to as a chemically stabilised emulsion. The droplets are less than 20 microns in size, and the water is white. The white colour indicates that the emulsion must be split to allow the oil to be removed. Metal working fluids, coolants, lubricants, motor oil, hydraulic fluids, and other fluids are sources of such oils.

>Dissolved oil

These are oils from the light end of the oil spectrum, like benzene, toluene, and xylene. The molecules have a diameter of less than five microns. Activated carbon removes them very effectively.

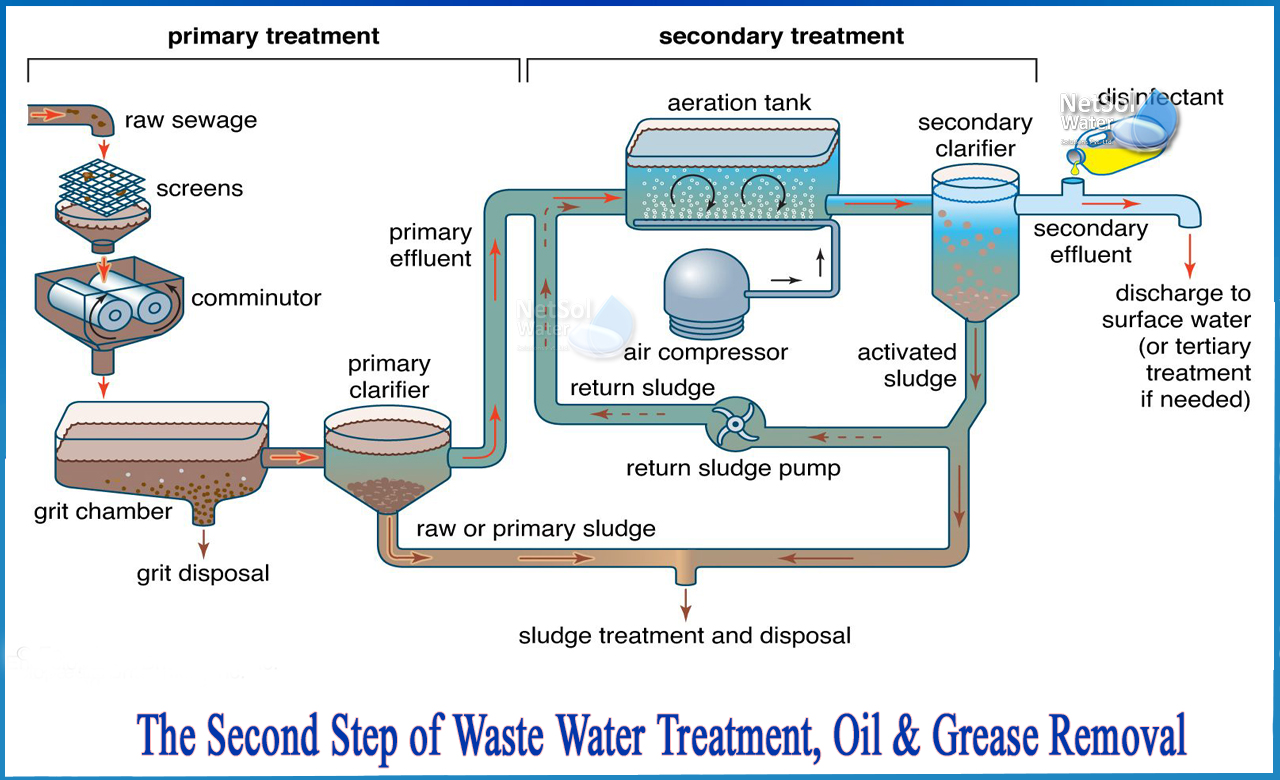

The process of removal:

1-The chamber consists of a baffle situated in the centre of the tank

2-This baffle is located few feet above from the bottom of the chamber

3-Oil and grease accumulated at the top of the tank, i.e., on the inlet side of the tank

4-It has to be removed regularly

5-From the tank bottom, grit is removed using a pump feeding it to a filter press

For more information on oil and grease removal, consult Netsol Water.