The Basics of Wastewater Treatment Plants

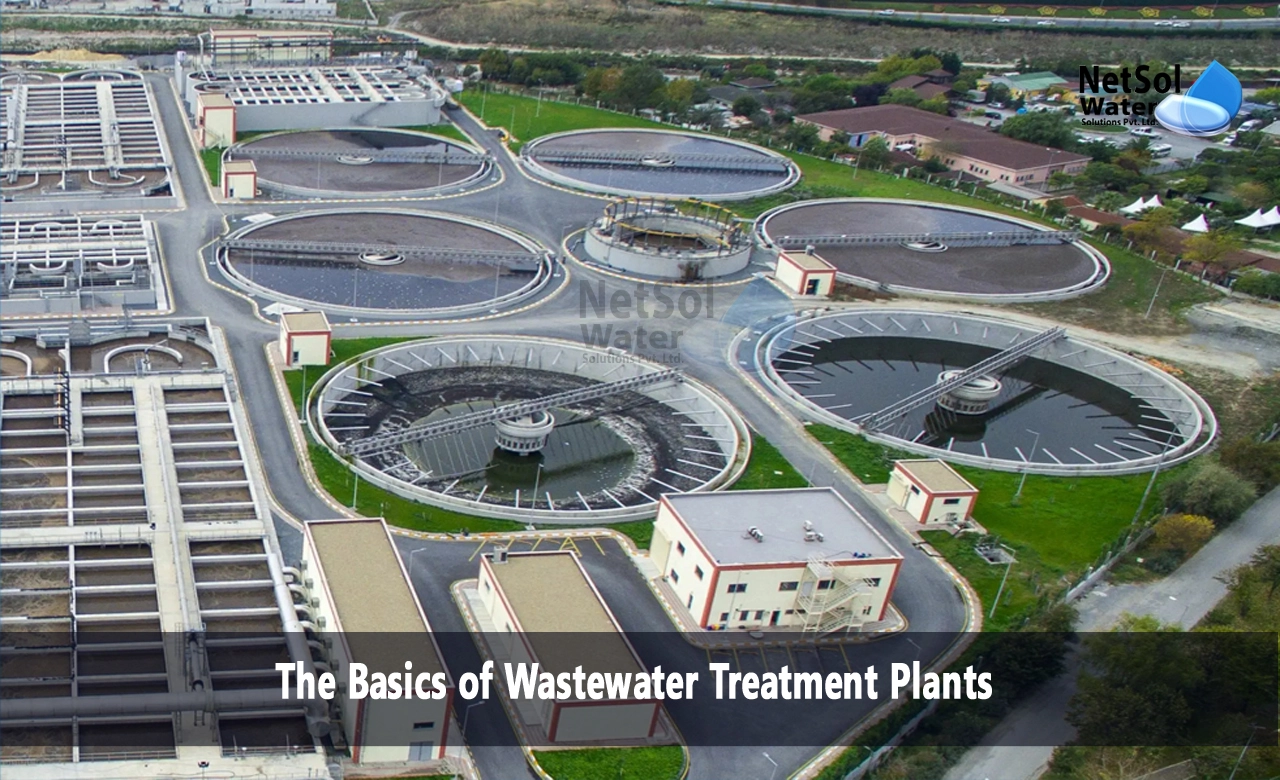

Wastewater treatment plants (WWTPs) operate almost invisibly within communities, quietly conducting the vital task of cleansing billions of gallons of used water daily. Their elaborate infrastructures contrast starkly with simple sinks and sewers funneling in society’s collected muck. Yet amazingly, out flows cleansed water ready to reenter natural environments. Just how do WWTPs transform raw sewage and runoff into purified flows safe for downstream use?

Preliminary Screening and Settling Removes Floatables and Grit

Incoming wastewater first passes through screens trapping larger debris like rags, sticks and litter. Scrapers clear trapped trash headed for landfilling. Flows then slow through grit chambers where sediments and heavier inorganic particles settle out from lighter organic suspended solids. These primary clarifiers remove nearly half the solids along with buoyant fats and oils skimmed separately. Pretreated water rolls on cleaner for further processing while collected solids start their own handling pathway.

Aeration and Activated Sludge Digestion

After preliminary filtering, wastewater rich in organic waste moves into aeration tanks bustling with aerobic bacteria, fungi and protozoa thriving as activated sludge flocs and biofilms. Diffusers deliver ideal oxygen levels sustaining microbial metabolism as they voraciously consume soluble organics. Through this approach, microorganisms remove over 85% of incoming organic carbon, nitrifying ammonia into nitrates. Clarifiers then separate cleaner water from sludge biomass for recycling to maintain a healthy digester culture.

Advanced Nutrient Capture Through Biological Uptake

Secondary treatment removes most organics but some nutrients like nitrogen and phosphorus compounds still discharge, feeding algae and causing eutrophication in receiving waters. So some plants include anoxic tanks where alternating oxygen levels encourage specific “supermicrobes” bioengineered to accumulate then strip excess nutrients into polymeric storage granules through amplified luxury uptake and cyclic intracellular storage. Controlled microbial manipulation thereby extracts otherwise limiting nutrients sustaining growth.

Tertiary Polishing Using Chemical or Physical Methods

Following biological processing, many facilities include supplemental tertiary treatment steps like media filtration, UV irradiation or chemical oxidation targeting specific remaining contaminants. Sand filters grab microscopic particulates above bacterial proportions. UV light mutates DNA/RNA strands of pathogens unable to shield radiation damage. Chlorine oxidizes any lingering organics or toxic compounds. Such polishing methods ensure final effluents reach safe purity standards before plant outlet discharge.

Continual Solids Separation and Resource Recovery

Throughout active treatment, clarifiers and settling ponds constantly harvest thickening biological sludge. Further processing the separated biosolids creates side products or safely eliminates waste. Digesters allow anaerobic bacteria to consume organics, releasing methane gas fueling heating and electricity. Dewatering steps like drying beds or centrifuges reduce volumes headed for disposal. Dried solids can amendments to fertilize crops or get incinerated to generate power, recovering embedded nutrients and energy before final ash disposal.

Down the Drain Then Back to Nature

Domestic, industrial and urban drainage all funnel into WWTPs as ickily contaminated influx. Yet through a carefully engineered sequence separating solids from liquids then methodically cleaning the flow using screens, skimmers, clarifiers, digesters, microbes and chemical polishers, public facilities transform society’s nutritive and toxic muck into purified, decontaminated water safe to discharge into groundwater or surface waters. They also process problematic biosolids into beneficially usable byproducts rather than waste needing disposal. Such effective, reliable infrastructure forms the overlooked backbone allowing modern density and cleanliness!

Conclusion

Wastewater treatment plants operate as mostly hidden high-tech facilities conducting the critical purification of civilizations’ used water flows, managing contaminants and protecting downstream environments using combined physical separation, biological digestion, supplementary chemical treatment and continual resource recovery processes. Their effective transformation of discarded nutrients and toxins into clean effluents and usable byproducts is an engineering feat essential for urban sustainability yet sorely underappreciated by societies simply expecting pristine conditions supporting public and ecological health after flushing away their waste downcommon drains.

Do you need an advice or assistance on selecting the best water and waste water treatment unit? We have solutions for all your problems!

Let us know your problem, our experts will make sure that it goes away.

For an assistance or related query,

Call on +91-965-060-8473 Or write us at enquiry@netsolwater.com