What Type of Technologies used in prefabricated STP Plant?

Prefabricated Sewage Treatment Plants have revolutionized wastewater treatment in urban and rural locations. These systems handle sewage management difficulties with small, efficient and cost-effective solutions. As populations rise and environmental rules tightenthe need for innovative wastewater treatment technologies has increased. Prefabricated STPs satisfy this demand by blending advanced technology with modular architecture, enabling rapid deployment and superior treatment.

Fundamentals of Prefabricated STP Plant

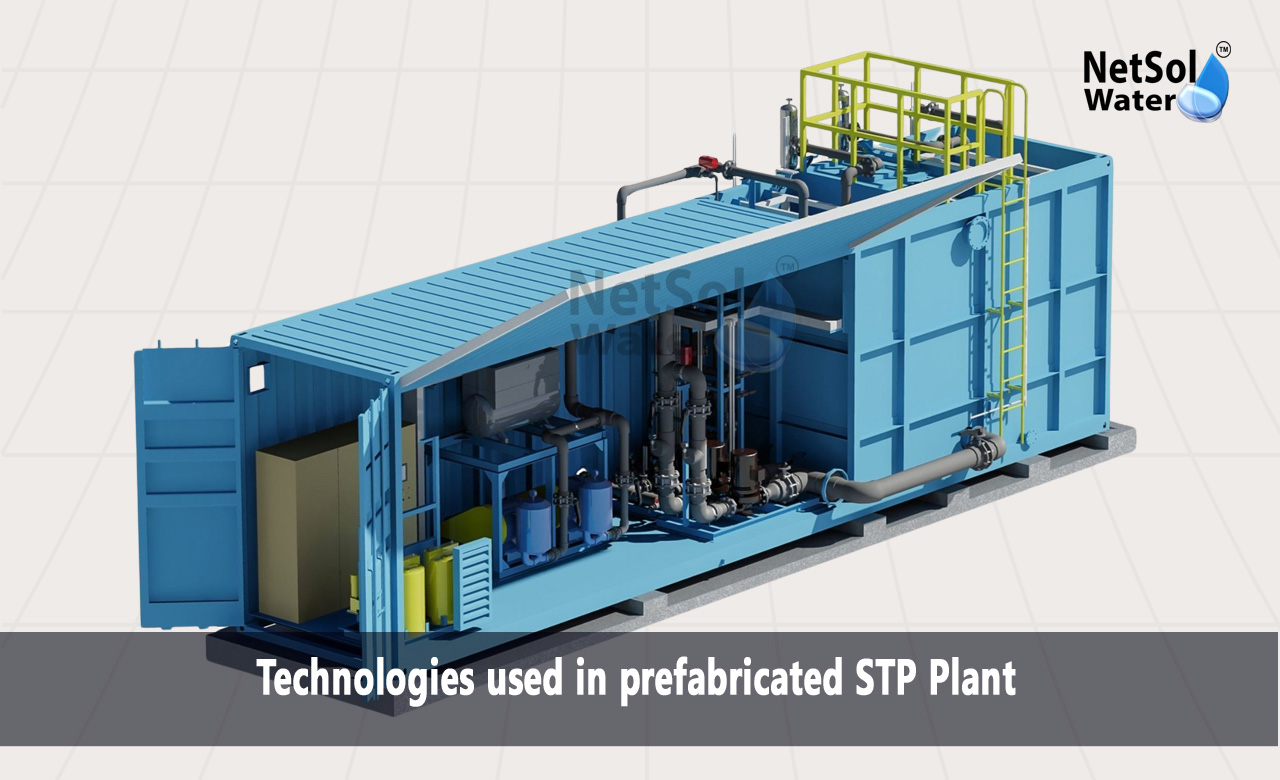

Prefabricated STPs stand differently from regular sewage treatment plants built on-site. Factories generate these pre-engineered systems in regulated surroundings. Their modular construction enables for easy travel and quick setup at the desired place.

These systems excel at delivering complete wastewater treatment in a compact size. Shipping containers or similar structures commonly hold prefabricated STPs, making them excellent for regions with limited space or problematic terrain. Their modular design also allows municipalities and enterprises to rapidly scale their treatment capacity as needed.

Primary Treatment Technologies

The first stage of sewage treatment handles big solid particles and debris in incoming wastewater. Prefabricated STPs generally incorporate advanced screening and grit removal technology during this early treatment phase.

Mechanical Screens automatically collect and remove bigger materials like plastics, rags and trash using fine mesh screens. The device then disposes of the trapped debris preventing clogs down the line.

Grit Chambers remove heavy inorganic particles like sand and gravel through gravitational settling or vortex separation. This stage shelters downstream equipment from wear and tear and lightens the load on the rest of the treatment system.

Secondary Treatment Technologies

Secondary treatment operations represent the core of any prefabricated STP removing most organic matter and suspended particles from wastewater. Several novel technologies increase the efficiency and effectiveness of this key stage.

Hybrid Granular Sequential Batch Reactor (hgSBR), combines the benefits of granular sludge with sequential batch operation. The hgSBR procedure uses specialized bacteria that create dense granules, achieving higher treatment efficiency in less space.

Membrane Bioreactor (MBR) technology integrates biological treatment with membrane filtration generating top-quality effluent for reuse. The membranes hold back biomass and create pure water without needing extra clarifiers.

Moving Bed Biofilm Reactor (MBBR) employs small plastic carriers to facilitate biofilm formation, increasing the surface area for biological therapy. MBBR systems achieve excellent treatment efficiency in a compact footprint making them appropriate for prefabricated STPs.

Also Read: Sewage Treatment Plant Manufacturer

Tertiary Treatment and Advanced Polishing

Prefabricated STPs often contain modern tertiary treatment technology to meet rigorous effluent quality standards and permit water reuse. These techniques target residual pollutants, pathogensand nutrients in treated wastewater.

UV Disinfection takes unwanted germs using ultraviolet light delivering a chemical-free alternative to standard chlorination. UV systems integrate effortlessly into prefabricated STPs, ensuring safe and reliable disinfection.

Membrane Filtration technologies include ultrafiltration and reverse osmosis filter out small particles, dissolved solids and trace pollutants. These systems create high-quality effluent suited for numerous reuse applications.

Nutrient Removal procedures use specialized biological or chemical methods to strip excess nitrogen and phosphorus from treated wastewater. This procedure inhibits algal overgrowth in receiving water bodies and meets severe discharge requirements.

Control and Monitoring Systems

Advanced control and monitoring technologies drive the efficiency and dependability of prefabricated STPs. These technologies enable peak performance and remote operation and maintenance.

SCADA Systems monitor and control all treatment processes in real-time. Operators can change parameters remotelyproviding smooth functioning and quick response to difficulties.

IoT Integration has changed prefabricated STP management. Sensors and connected devices across the system continuously transmit data on water quality, equipment performanceand energy use enabling predictive maintenance and optimization.

Energy Efficiency and Sustainability

Prefabricated STPs increasingly incorporate energy-efficient technologies and sustainable practices to decrease their environmental footprint and operational expenses.

Energy Recovery systems use anaerobic digestion to produce biogas from sewage sludge, which can fuel electricity generation or heating for the treatment process.

Solar Integration provides many prefabricated STPs with solar panels to balance energy use, making them suitable for off-grid or remote areas.

Water Reuse Systems use advanced treatment methods to provide high-quality effluent for diverse applications, such as irrigation, industrial processes or groundwater replenishment.

Conclusion

Prefabricated STPs represent a significant advancement in wastewater treatment technology, providing varied and efficient solutions for sewage management issues. These tiny treatment facilities pack a wide range of new technologies to give best performance in a small footprint from advanced biological processes to cutting-edge control systems.

As we face environmental challenges and water scarcity prefabricated STPs will likely play an even bigger role in sustainable water management. Ongoing research and development in resource recovery and energy efficiency position these systems to determine the future of wastewater treatment and water reuse.

For any assistance

Call on +91-965-060-8473

Or write us at enquiry@netsolwater.com