What is Suspended growth treatment process in SBR?

It is a wastewater treatment process in which microorganisms and bacteria that treat waste are suspended in wastewater. Waste flows around them.Various modes of the activated sludge process use suspension growth reactors.

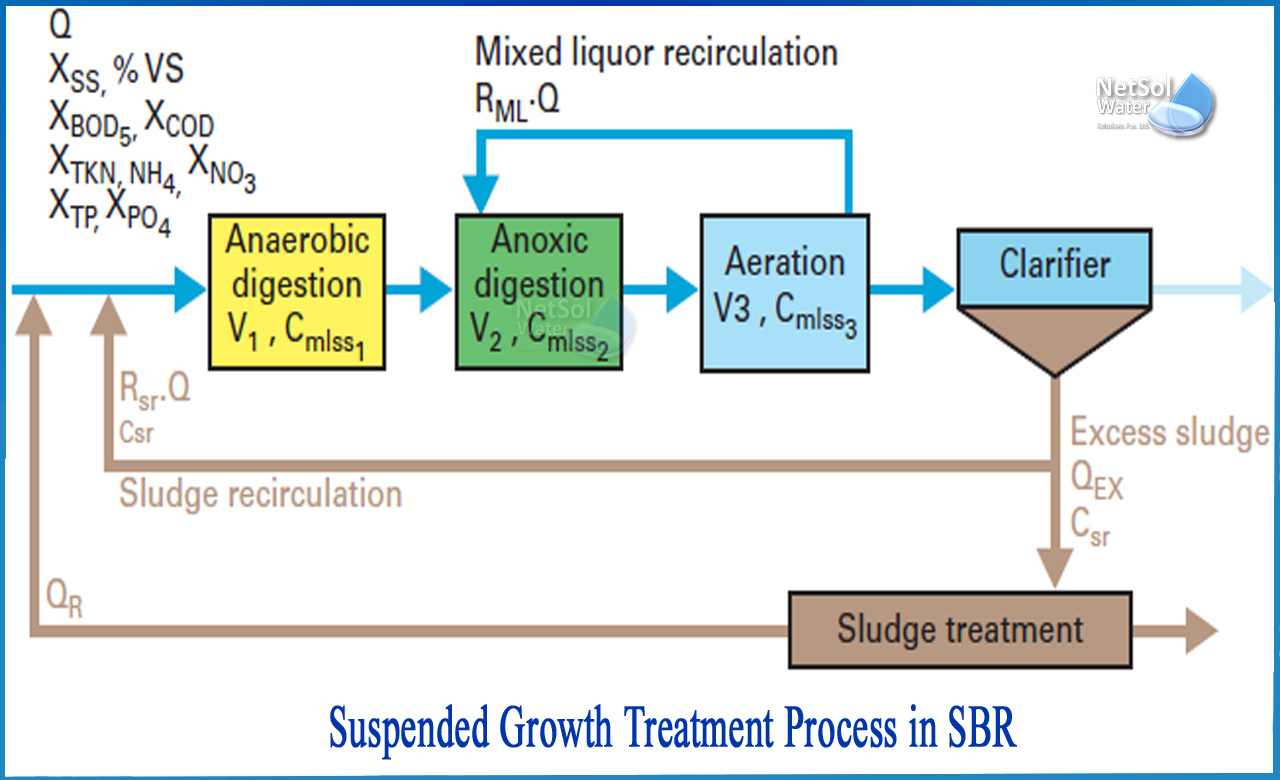

The process followed

In aeration tank where the purified water meets the bacterial mass, then bacterial growth happens. It isa purification device that separates purified water from bacterial culture. A recirculation device is used to return the biological sludge collected from the purification device to the aeration tank.

This tank mixer ensures the best possible contact between bacterial cells and their nutrients, promotes widespread diffusion of oxygen into areas that require oxygen, and prevents the formation of deposits. Often the same arrangement is used for aeration and mixing.

In the so-called "Sequential Batch Reactor" (SBR), there are various stages.

Aeration-sedimentation is performed in batches with the same structure. It is in sedimentation mode because it is first aerated and mixed, then not aerated. Therefore, this is just one variation of the activated sludge system. A water treatment plant equipped with an activated sludge system can first be identified by its F/M ratio which is used to classify different processes.

These relationships lead to the use of characteristic coefficients that depend on the nature of the substrate and the physiological state of the biomass. This is largely determined by the age of total sludge or simply aerated sludge.

The whole process is shown below:

Oxygen demand and excess sludge production

When biodegradable organic matter is consumed by large numbers of microorganisms in aerobic media then oxygen is required for these microorganisms for cell division (synthesis of organisms) regeneration, and autoxidation of those cell masses.

What is excess sludge?

On the other hand, the production of excess biological or inert substances is called excess sludge. It is difficult to experimentally determine the active concentration MLSS in activated sludge. However, it is possible to measure the volatile substance concentration and the total MLSS (mineral and organic concentration) concentration.

A little History

Until the end of World War II, the dimensions of the water treatment plant remained very careful. Only after this date was the development of high load systems and the use of combination tanks (aero accelerators, oxyrapids, etc.), the "bio-soapization or contact stabilization" process and wastewater quality. Currently, the quest for high purification efficiency and the need to remove nitrogen and phosphorus renews interest in low pollution treatment systems.

Conclusion

It is an important part of the wastewater treatment process. It is critical for facility managers and water treatment specialists to remain vigilant and proactive in both water treatment and system maintenance.

Remember that the wastewater professionals at Netsol Water can assist you in determining your nitrogen and phosphorous levels and developing a plan for better wastewater management.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.