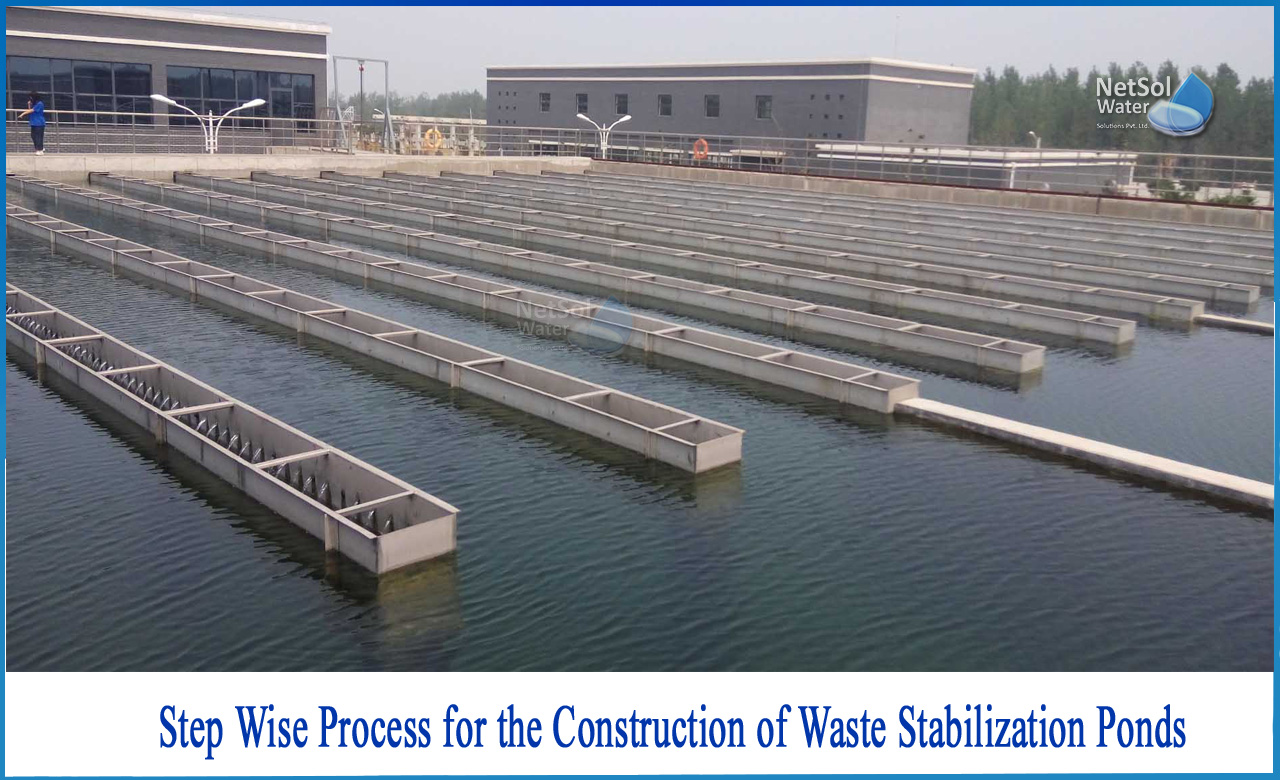

What is the process for the Construction of Waste Stabilization ponds?

Waste stabilization ponds are man-made sanitation water bodies for treating wastewater by naturally occurring processes and under the influence of sunlight, air and micro-organisms. These ponds can be aerobic, anaerobic and facultative. However most of the ponds exist in facultative nature. The main function of these ponds is the removal of carbon containing organic matter.

Waste stabilization ponds can treat variety of wastewater that include inputs from preliminary treatment, secondary treatment or untreated wastewater.

The output from these ponds include treated effluent, sludge and biogas. Sludge that gets accumulated at the bottom of these ponds need to be removed periodically.

Three distinct zones exist in this type of pond

The top zone is aerobic in which the photosynthesis and aerobic biodegradation takes place.

In the bottomzone the organic matter present in wastewater and cells generated in aerobic zone settle down and undergoes anaerobic decomposition.

The intermediate zone is aerobic and partly anaerobic. The decomposition of organic waste in this zone is carried out by bacteria which are facultative in nature. The problems associated with the anaerobic reaction is eliminated due to the presence of top aerobic zone.

Maintenance of an aerobic condition at top zone is important for proper functioning of stabilization pond, and it depends on solar radiation, wastewater characteristics, BOD loading and temperature. Functioning of these ponds is comparable with conventional wastewater treatment.

Step by step guide to construction of waste stabilization ponds

Step 1: Selection of site

The overall economics, design, and operation are greatly affected by the nature of the site. Site selection is particularly important when waste stabilization ponds are contemplated.While selecting the site for waste stabilization pond, following factors should be considered:

a) Water table should be present at a greater depth.

b) Soil should be impermeable. Silt and clay soils are ideal for this construction.

c) Ponds should be located 500m away from any residential area. Consideration must be given to nearby residential areas. The requirements concerning distance from residences are naturally dependent on local customs, climate, and the type of treatment process planned.

d) Surface drainage should be kept away from pond sites.

Step 2: Size and shape

The size of the waste stabilization ponds is fixed on the basis of present flow and load. It is very important that the space should be readily available for the addition of similar or different units as the need arises.Thus the site must be large enough for any anticipated expansion. The terrain must be such that the pond or ponds will meet the shape and size requirements of the process design.

The dimensions of stabilization ponds depends upon various factors like; quantity of waste that needs to be treated, climate of the area, processes required for treatment etc. Detention time usually has a very important role in designing the ponds. Ponds can be square, rectangular, oval or polygonal. The size and shape are so designed to maximize the detention time.

Step 3: Inlets and outlets of waste stabilization pond

Inlet pipelines used should be of suitable material keeping in consideration the quality of wastewater.Type and position of inlet has a significant impact on efficiency of treatment. Multiple outlets can be provided at the same rate as for inlets. Outlet positioning has to be selected after the designing of pond type and inlet position.

Step 4: Flow measuring devices

Flow measurement devices for inflow and outflow should be provided.It is desirable to provide a flow-measurement device wherever possible. Without influent flow measurements it is impossible to determine the loading of a pond system, and without effluent flow measurements it is impossible to determine the percolation and evaporation losses. If only one flow measuring device can be provided, it is preferable to determine the volume of the influent.

The location of a treatment facility may be fixed by some previous decision involving the location of an outfall sewer, by the availability of dilution water, or by some other local requirement.

What can we offer?

Netsol Water have expertise in wide range of water and wastewater treatment technologies including the construction of waste stabilization ponds. We can customize wastewater treatment plants that will cater to all your needs and at the same time effectively treat different types of water and wastewater.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.