Water softener sizing tools are on the internet to help consumers choose the right softener. Unfortunately, most of these tools do not take into account the efficiency of the water softener in their calculations.

As a result, a soft finish of the right size is often selected, but a large amount of salt is used (many) rather than an efficient model of the right size that uses minimum salt.

Why is this happening?

It's a coincidence that many retailers, both online and in stores, don't understand the concept of fabric softener salt efficiency and don't incorporate it into their size models.

If you haven't read it yet, it's a good idea to read the linked article detailing the efficiency of salt and understanding the true capacity of a water softener.

Why do you need to worry about efficiency?

The efficiency of the water softener determines the amount of salt that needs to be purchased, the amount of salt that needs to be transported, and the amount of salt that is released into the environment. By sizing the fabric softener and considering the efficiency of its salt, you can buy a fabric softener that does not run out of soft water and uses as little salt as possible. Over the useful life of the water softener, this leads to significant cost savings and easy handling.

How to determine the proper size of a water softener?

The correct dimensions of a water softener are to adapt certain water qualities and consumption to a well-sized system that minimizes salt consumption and maximizes soft water capacity.

The first step to correctly dimension the fabric softener is to calculate the "daily fabric softener requirements". It's just a measure of how rough the soft finish needs to be removed each day. The daily need for water softening is calculated based on water hardness information and water consumption.

1-Water hardness:

This is a measure of how much calcium and magnesium are dissolved in water. This information is displayed in mg/L (milligrams / litre) or GPG (particles/gallons), depending on where the water quality test is being performed. Grains per gallon is an industry standard method for discussing water hardness. If you dive around 17.1 mg/l, it will be converted to GPG. One "particle" of water hardness is equivalent to 1/7000 of a pound.

When considering the purchase of a water softener, it is very important to know the hardness of the water. Guessing this number will result in incorrect system size. When programming a soft finish, you will be asked for a hardness value. If you are using tap water, you can usually get the hardness level from your local water company. Their annual report can often be found online. If the water contains iron, the hardness value needs to be corrected. For every 1.0 ppm or mg/L of iron, approx. 3 GPG hardness should be added to the total hardness value.

2-Water consumption:

The second factor for calculating daily water softening requirements is household water consumption. The most accurate way to calculate this is to look at water charges, which indicate total usage over a period of time (usually one month). You can use this information to determine how much water your household uses on average each day. Without this information, simply multiply the number of people living in your home by 75 gallons a day. This allows you to estimate your daily water usage fairly accurately.

Now calculate the daily water softening requirements-

Multiply your daily water consumption by the hardness of the water (corrects the iron content). This number is your daily softening requirement. Here is an example:

Hardness: 30 grains per gallon.

Daily water usage: 4 people x 70 gallons per day = 280 gallons per day.

Daily softening needs = 30 grains per gallon x 280 gallons per day = 8400 grains per day.

In the above example, the fabric softener removes 8400 grains per day. Soft finishes are usually sized to regenerate about once a week.

Choose a soft finish that suits your needs

At this point, the local situation and water usage were used to determine the amount of softening required per day. Water softeners are usually sized to regenerate about once a week.

Why once a week?

Weekly regeneration balances keeping the resin bed fresh and preventing excessive valve wear. The water softener valve contains moving parts, but the moving parts move only when the softener is regenerating. Weekly regeneration also keeps water consumption low. The water softener uses about 50 gallons during regeneration.

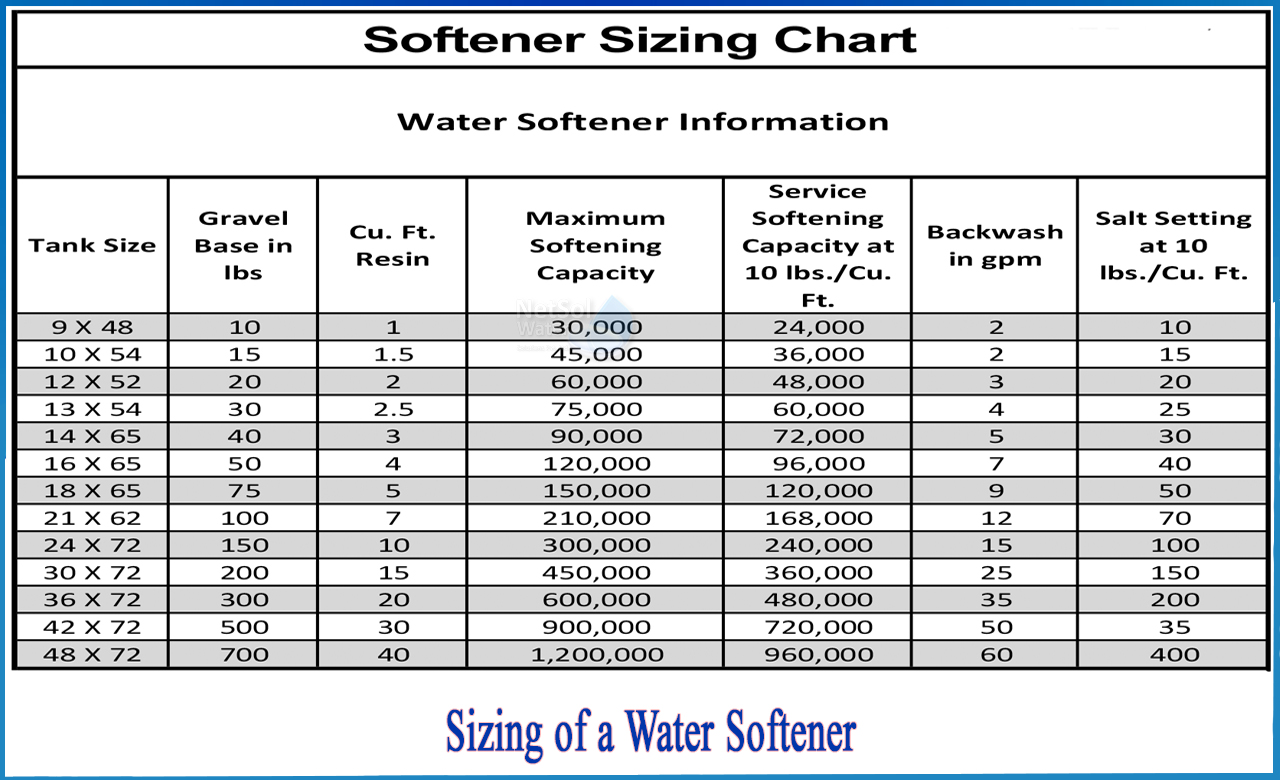

If we take a softening requirement of 7500 grains per day, which is multiplied by 7 days, we need a softening agent that can soften the total hardness of 52500 grains in order to regenerate once a week. So what size water softener provides a total softening capacity of 52500 grains?

This is where extensive misinformation found on the Internet and elsewhere can hide the real answer.

A quick look at the online and in many stores reveals the abundance of 24,000/32,000/48,000 and 64,000 water softeners. At first glance, the 64000 grain system seems ideal for the above example, which requires a total softening capacity of 52500 grains.