Plant Managers and ETP Operators in effluent treatment plants have the responsibility, to keep a healthy balance of microorganisms. To treat effluent effectively and safely, "good" bacteria are required, but "bad" bacteria must be avoided because they could harm the operation of the plant, and contaminate the environment if discharged without any treatment.

Thus, this is a big issue for managers and operators in ETPs.

If contaminated water is mistakenly released from a treatment facility, it can have devastating effects on fisheries, wildlife habitats, and our own health. This is the reason plant managers and operators are so focused on managing treatment operations, which are safe, efficient, and compliant.

Current testing procedures for bacteria levels and types are costly, resource-intensive, and time-consuming. Industries frequently rely on other laboratories and testing partners, whose turnaround times for results might be as long as 5 days. It may be not the best situation when you suspect an issue!

The effluent treatment plant operation has to be improved and made easier for the industry. And, that's where cutting-edge innovations like artificial intelligence (AI) come into play!

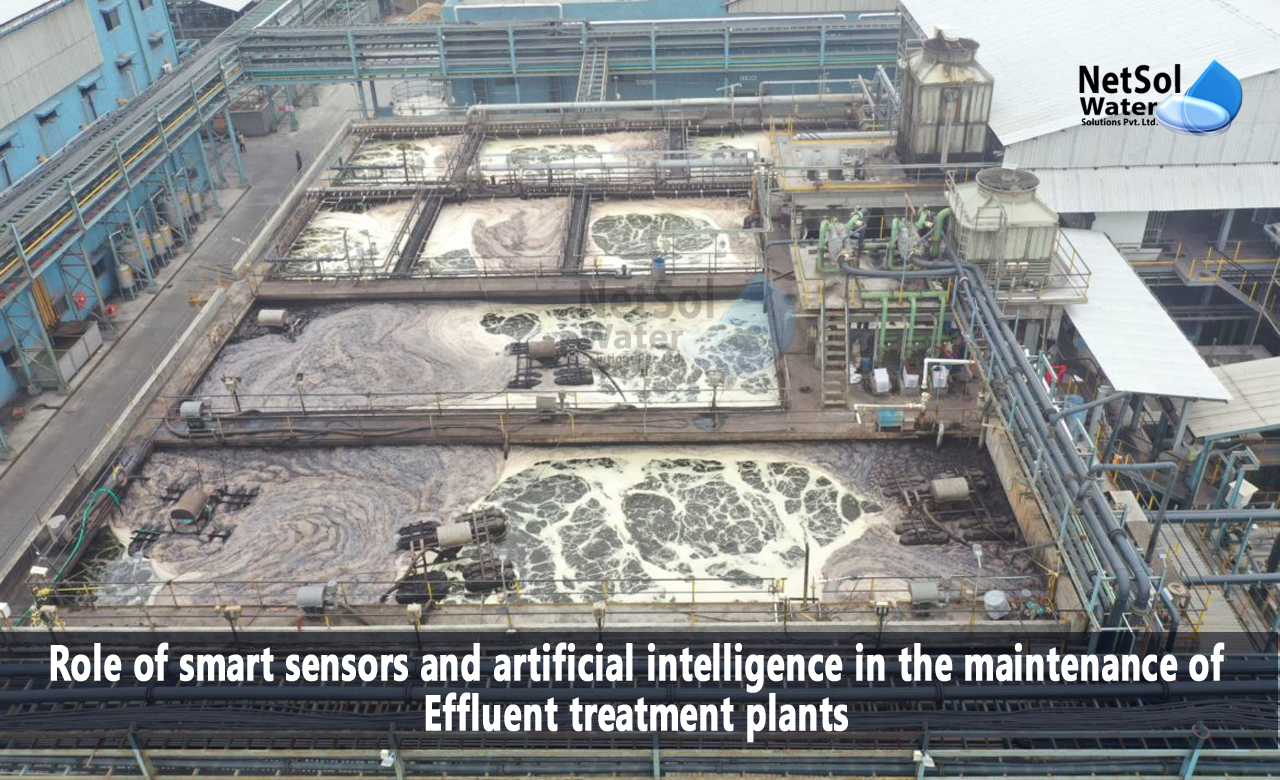

Role of smart sensors and AI in the maintenance of ETP

Artificial intelligence is the capacity of a computer program or digital device, to carry out operations often done by people.

Let’s understand the role of smart sensors and artificial intelligence in the maintenance of ETPs!

1. AI and smart sensors recognizes filament disturbances to spot and prevent problems.

Filaments are bacteria and fungus, which can be good or bad. Positively, they can increase the floc structure's stability. They may bulk up and froth, which is bad.

AI can aid with the effluent treatment process by addressing issues with sludge expansion, and enhancing aeration and pump performance. Several sludge photos are used to train AI testing platforms. They are therefore able to detect problems with human-level accuracy and quickness.

2. AI uses sensor information from motors to predict equipment faults.

AI can increase operational effectiveness and cut expenses by managing the daily flow, and keeping an eye on ETP's systems and automation processes.

In order to provide an early warning of asset degradation or failure, machine learning algorithms are able to recognize anomalous sensor behaviour. AI technology can also forecast when maintenance is necessary by monitoring things like, the energy usage of equipment and leaks, bursts, and pollution problems.

All of this enables Plant Managers and Operators to take decisions, based on solid information much more quickly.

3. Future effluent quality is predicted by AI.

When it comes to reducing microbiological hazards and improving operations, ETP's management decisions might be based on the effluent quality.

All ETPs still have significant difficulties with monitoring effluent quality, especially now that stricter effluent limits and regulations are in place.

4. AI responds to operator inquiries concerning protocols.

Effluent treatment plant operators frequently employ "grab sampling" to gain some insight into the procedural flow. Nevertheless, this approach necessitates constant work and only offers a picture of the situation, rather than a real-time one.

Operators can spot patterns and trends by automating the sampling process. Additionally, a strong AI testing platform may offer managers in a plant recommendations and analyses, to assist them to comprehend what's happening and what needs to be done.

The sludges that are continuously analysed don't alter in composition, because they no longer have to travel from plant to lab for processing, saving plant managers the inconvenience of transferring samples to a lab or secondary location.

Conclusion

Data extraction, processing, and interpretation are all capabilities of AI applications. Operational cost savings and preventive maintenance are the end consequence. This is essential since ETPs are currently subject to stringent pollution restrictions, as well as more stringent rules for energy efficiency and resource recycling.

How can we assist?

Netsol Water is the best manufacturer of water and wastewater treatment plants in India. We provide advanced effluent treatment methods in effluent treatment plants. With the help of innovation and market expertise, we can provide smart sensors and artificial intelligence to maintain ETP properly.

For further information, contact us at +91 9650608473 or email at enquiry@netsolwater.com