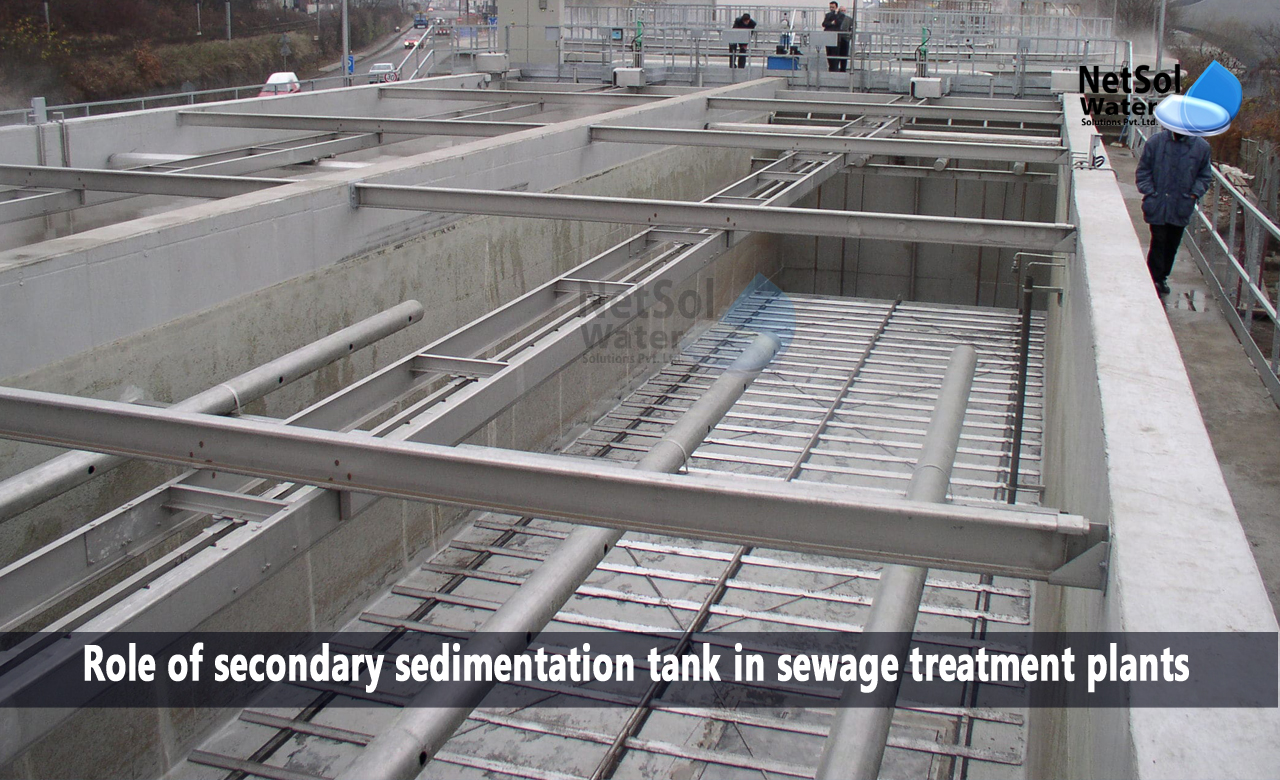

The Secondary Sedimentation Tanks are spherical tanks with motorized scum and sludge collectors that rotate. Spray systems for scum removal and odour control, as well as pumps for tank drainage, are examples of auxiliary systems.

Clarifiers can be made of galvanized steel, stainless steel, painted steel, or aluminium. The choice is influenced by the wastewater's characteristics (especially if it contains chlorides), the economy, and regional customs.

What is the Role of secondary sedimentation tank in STP?

These settling tanks, which are frequently referred to as clarifiers, are used in activated sludge systems to separate treated water from biomass, settle sludge, and thicken it to the necessary extent, so that it can maintain the necessary biomass concentration levels, when the sludge is returned to the tank inlet.

In order to prevent any unintended changes brought on by a prolonged lack of aeration, special attention must be paid to the method used to collect this sludge. Large amounts must be collected, and the biological nature of the sludge needs tight control, over their contact time on the tank bottom.

How does secondary sedimentation work?

1: Each tank has a flap gate that allows floodwater to enter so that the structure won't float, while also preventing wastewater outflow.

2: Each tank's bottom is used to introduce the Aeration Structure's effluent, which rises through the center column before being disseminated throughout the sedimentation zone.

3: Sludge that has settled is removed using collecting pipes on the submerged collecting rake arms, and hydraulic differential flows to a chamber towards the top of the middle column, where sludge is collected.

4: Sludge removal in the tank can be balanced by setting the adjusting valves, on the top end of each collecting pipe.

5: The sludge is then pumped and separated into RAS and WAS, before flowing back to the wet well in the aeration structure.

6: Scum is removed from the wastewater's surface in each tank, and pumped to either the head-works or the Sludge Thickener from a sump in the Aeration Structure.

7: Three-quarter horsepower motors with torque overload protection are used, to power the sludge and scum collectors. The self-priming centrifugal drain pumps are powered by motors, with 7 to 15 horsepower.

8: During power interruptions, sewage flow into the secondary sedimentation tanks will continue. The tanks have a backup power source and will function even if there is a power outage.

Use of Secondary Sedimentation Tank

The nominal surface loading for Secondary Sedimentation Tank No. 1 is about 450 gallons per square foot per day, whereas the nominal surface loading for Secondary Sedimentation Tank No. 2 is around 600 gallons per square foot per day.

When the design maximum peak overflow rate of Tank No. 1 is surpassed, Secondary Sedimentation Tank No. 2 provides extra secondary sedimentation capacity. It also serves as a backup tank in case Secondary Sedimentation Tank No. 1 needs maintenance.

Conclusion

When sedimentation is used to treat wastewater, a secondary treatment is utilized to remove soluble contaminants with microorganisms, such as a trickling filter, activated sludge, or another purification procedure.

Sewage from the aeration structure enters each secondary sedimentation tank through the center column, flows into them, and is then disseminated across the sedimentation zone.

The active sludge settles out as the sewage moves through the sedimentation zone, and the clarified sewage then runs down the output pipe, and over the weirs of the circumferential wash to reach the chlorination structure.

Leading manufacturers of sewage treatment plants in India!

Netsol Water is a top manufacturer of wastewater treatment facilities, and industrial and commercial water treatment facilities in India.

The experts at Netsol can go over sedimentation and other wastewater treatment options, which we offer to improve the quality of your water. We also offer services for treating wastewater. The services we provide and how they can help your municipality can be explained by our experts. For further information, contact us at +91 9650608473 or enquiry@netsolwater.com