Role of Screen and Grit Chamber in Wastewater Treatment

“WASTEWATER IS NOT A WASTE UNTIL WE WASTE IT”

WHY TO REMOVE SOLIDS AND GRIT FROM WASTEWATER?

We remove large solids and grit from wastewater because these solids and grit can interfere with the wastewater treatment processes.

HOW TO REMOVE LARGE SOLIDS AND GRIT FROM WASTEWATER?

By Preliminary treatment:

Preliminary treatment includes the following steps:

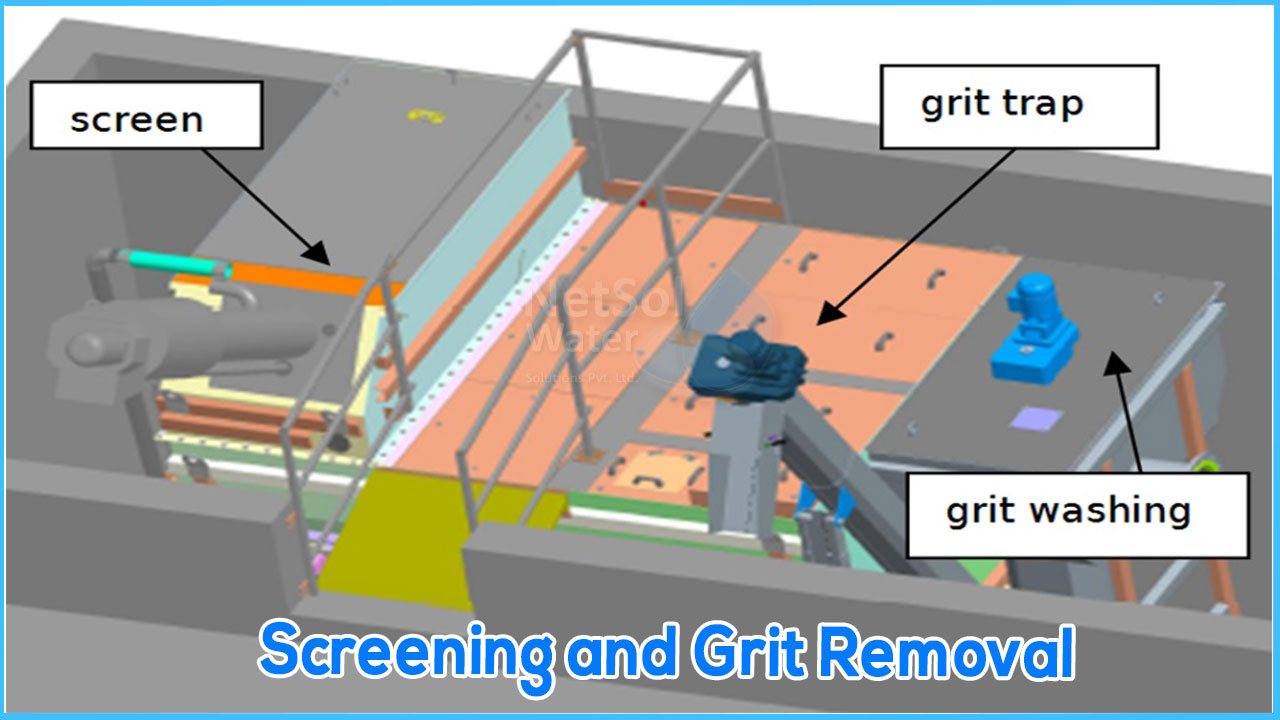

- 1. Screening.

- 2. Grit removal.

- 3. Septage handling.

- 4. Odor control.

- 5. Flow equalization.

SCREENING:

The first step done at wastewater treatment plants (WWTPs) is screening. Screening eliminates objectslike paper, cloth, metals and plastics. These objects need to be separated at the beginning of the treatment process. These objects can damage process equipment’s like pumps, valves, pipe lines and appendages, thus reducing the effectiveness of the treatment process.

WHAT IS A SCREEN?

A device with an opening, that is used to hold or retain the floating objects like cloth, paper etc., that is found in the wastewater.

ELEMENTS OF THE SCREEN:

The screening system may consists of the any of the following:

- 1. Perforated plates.

- 2. Gratings.

- 3. Wire meshes.

- 4. Parallel rods.

SHAPE OF THE OPENING:

The shape can be circular or rectangular.

SIZE OF THE OPENING:

Depending on the size, can be:

- 1. Coarse screens.

- 2. Fine screens.

COARSE SCREENS: These screens eliminate the solids and debris from wastewater, have openings of 6 mm or more.

TYPES OF COARSE SCREENS:

- 1. Mechanically cleaned.

- 2. Manually cleaned Or Hand cleaned.

FINE SCREENS: Theseare used to eliminate materials that may create issues or problems in downstream processes in operation as well as in maintenance. Opening sizes for fine screens are 1.5 to 6 mm. Also there are very fine screens with openings of 0.2 to 1.5 mm. They are used for pre-treatment of industrial wastes to eliminate items that produce foam. They are continuously operated and cleaned mechanically. Fine screens are of two types:

- 1. Drum type.

- 2. Disc type.

Hand or manually cleaned screens need very less articlemaintenance.The labour cost is lower for mechanically cleaned screens as compared to manually cleaned screens.

GRIT REMOVAL

Grit consists of unwanted materials like aggregates, sand, gravel or heavy materials that have higher specific gravity than the organic solids that are present in the wastewater. Grit also consists of organic particles like food waste, eggshells, seeds, etc.

WHY DO WE REMOVE GRIT?

- 1. To prevent unnecessary abrasion.

- 2. To reduce wear of mechanical equipment.

Types of grit removal systems:

- 1. Aerated GC (Grit chambers)

- 2. Vortex-type GC.

- 3. Detritus tanks.

- 4. Horizontal flow GC.

- 5. Hydro cyclones.

FACTORS THAT ARE TAKEN INTO CONSIDERATION FOR CHOOSING A GC PROCESS:

- 1. Quantity of grit.

- 2. Features of grit.

- 3. Certain harsh effects on downstream processes.

- 4. HL requirements (head loss).

- 5. Cost.

Also the grit that is collected must be taken out from the chamber, then dewatered, washed and conveyed to the point of disposal. Grit removal is done usually by an automatic method but certain smaller plants also use manual method.