What are clarifiers?

Clarifiers are settling tanks equipped with mechanical means to remove solids deposited by sedimentation on a continuous basis. A clarifier is a device that removes solid particulates or suspended solids from liquids in order to clarify and/or thicken them. Solid contaminants settle to the bottom of the clarifier tank and are collected by a scraper mechanism. Sludge refers to concentrated impurities discharged from the tank's bottom, whereas scum refers to particles that float to the liquid's surface.

Coagulation and flocculation reagents, such as polyelectrolytes and ferric sulphate, can be added to the water before it enters the clarifier. These reagents cause finely suspended particles to clump together and form larger, denser particles known as flocs, which settle more quickly and steadily. This allows for more efficient and easy separation of solids in the clarifier, which aids in energy conservation. Using these processes to isolate the particle components first may reduce the volume of downstream water treatment processes such as filtration.

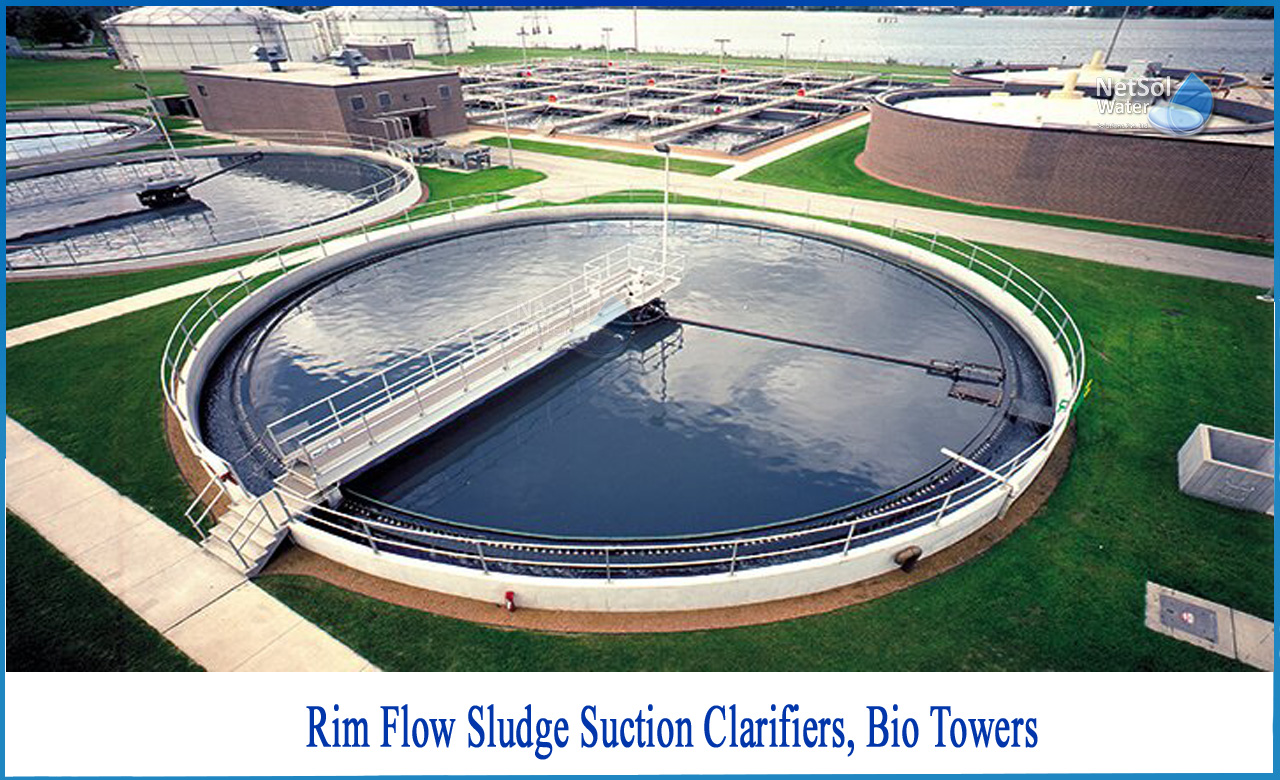

What are Rim-flow clarifiers?

Rim-Flow Clarifiers can be smaller than Centre feed clarifiers due to their higher hydraulic efficiency (50 to 80 percent more than Centre feed clarifiers), or the extra capacity can be used as a conservative factor when designing treatment plants. When installed in existing clarifiers, they provide the additional capacity required to relieve overload situations.

What are the applications of Rim-flow clarifiers?

1: Potable Water Treatment

Prior to the sedimentation process in the clarifier, coagulation and flocculation processes cause finely suspended particles to clump together and form larger and denser particles that settle more quickly and stably, allowing particle separation in the clarifier to occur more efficiently and easily – aiding in energy conservation. Using these processes to isolate the particle components first may reduce the volume of downstream water treatment processes such as filtration.

Sedimentation in potable water treatment typically follows a step of chemical coagulation and flocculation, which allows particles to be grouped together into larger flocs. This increases the settling speed of suspended solids and enables colloids to settle. Fine and suspended particles in water clump together as a result of polyelectrolytes and ferric sulphate. These coagulant chemicals can be used to treat water before it enters the clarifier.Following coagulation, flocculation using large mechanical paddles causes the coagulate to form denser particles that settle more easily. The water is then routed to the clarifier, where the clarified water is separated from the flocculated coagulate by allowing the heavier and larger particles to settle to the bottom of the clarifier.

The particles then combine to form a layer of sludge, which must be removed and disposed of on a regular basis. Clarified water can then be passed through granular filters to remove any remaining particles. Filtered water is then routed to a pumping station where it is stored and used.

2: Waste Water Treatment

For millennia, sedimentation tanks have been used to treat wastewater. Sedimentation is the primary method of removing floating and settleable solids from sewage. Primary clarifiers reduce the amount of suspended solids and pollutants in the suspended solids. Due to the large amount of reagent required to treat domestic wastewater, preliminary chemical coagulation and flocculation are generally avoided, with remaining suspended solids being reduced by subsequent stages of the system.

Coagulation and flocculation, on the other hand, can be used to build a compact treatment plant (also known as a "package treatment plant") or to further polish the treated water. Secondary clarifiers are sedimentation tanks that remove flocs of biological growth produced by some secondary treatment methods such as activated sludge, trickling filters, and rotating biological contactors.

3: Mining

Sedimentation, floc blanket clarification, and filtration are mining methods for treating suspended solids in mining wastewater. After dissolving the ore, the saturated borate solution is pumped into a large settling tank. Borates float on top of the liquor, while rock and clay sink to the bottom.

For designing, and manufacturing of waste water treatment plants, contact Netsol Water.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.