What are the Pros and Cons of Coagulation process?

To obtain the required treatment outcomes, each step in the wastewater treatment process is crucial. But, for the whole process, primary care is essential. Solids are greatly decreased throughout the primary treatment process. Subsequent treatment would be less successful without this step.

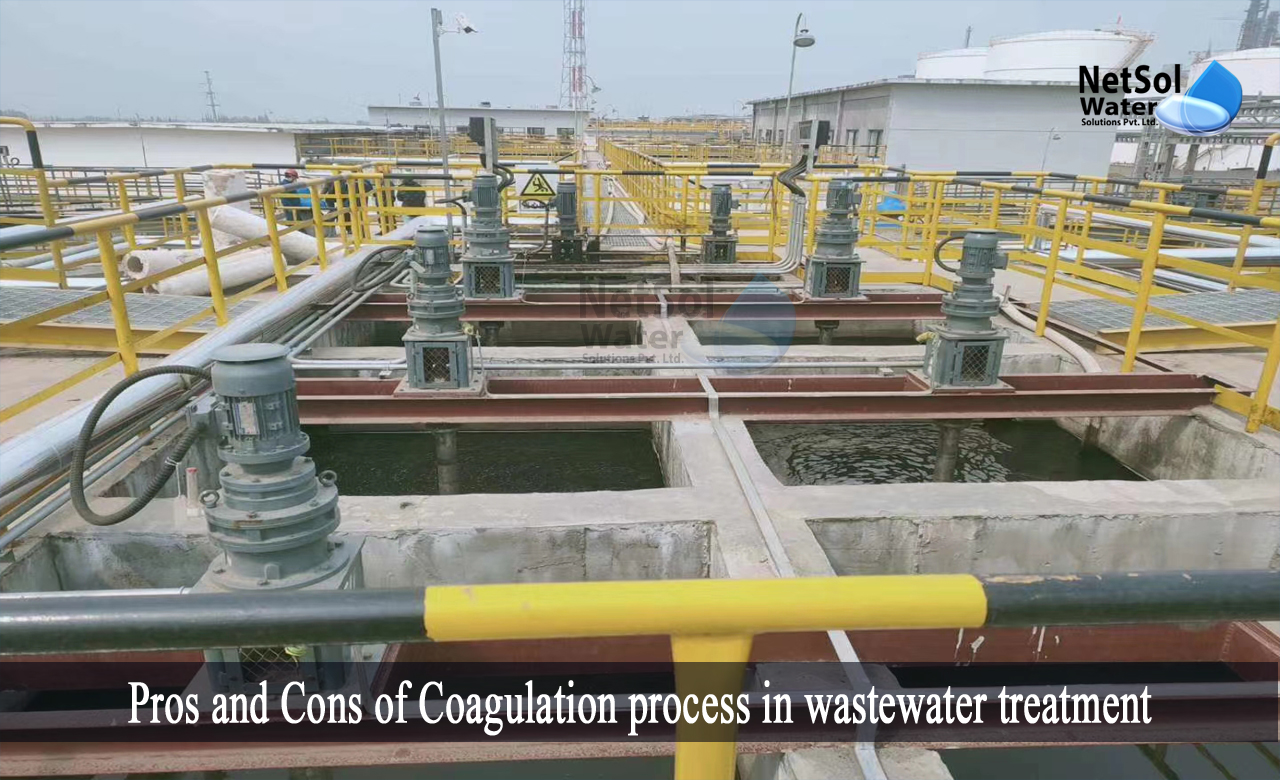

Coagulation is the technique used to treat wastewater, respectively. The procedure can be carried out in a variety of ways, using either chemical or non-chemical methods. The process of coagulation has its own sets of pros and cons in wastewater treatment.

What is Coagulation?

Total dissolved solids (TDS) and total suspended solids (TSS) levels in wastewater influents vary. Course screening and grit chambers will lower the TSS, but a more precise solids removal technique must come next. Although, filtration and sedimentation have been employed in the past, they are ineffective for removing many of the smallest particles.

Coagulation has gained popularity as a technique for lowering wastewater's TSS and, in certain situations, TDS. The charged particles in the solution must be made less stable, throughout this procedure. The particles resist one another due to their identical electrical charges, which delays their rapid settling. An opposite charge must be added to the solution, in order to destabilize this electrical charge, and allow the colloids and other minerals to aggregate.

What is Chemical Coagulation?

One popular technique for particle coagulation is chemical coagulation. In order to produce the necessary destabilized condition, this technique justifies the addition of a number of chemical additives. To neutralize the charged particles, chemicals like alum, ferric chloride, ferric sulphate, ferrous sulphate, and lime are sometimes utilized. Polymers, which help solids aggregate, are another type of supplements.

Pros of Chemical Coagulation

1: The primary justification for using chemical coagulation is that, it reduces the amount of time that solids would need to settle naturally.

2: The settling of smaller colloidal particles and mineral impurities can also be helped, by chemical coagulation.

3: These particles would normally pass through a later filtration system, since they might not settle during a sedimentation process.

Cons of Chemical Coagulation

1: At its foundation, chemical coagulation is an additive procedure. Despite the fact that it can do so, adding chemicals is still necessary to lower the number of solids in a solution. These additions can be difficult and necessitate a lot of jar testing. To process the influent effectively, the doses must be pretty precise. The variable composition of the wastewater source, may necessitate on-going dosage adjustment.

2: The addition of chemicals also causes a significant amount of sludge to be produced, which must then be processed and disposed of. Because of the added elements' nature, this sludge is also dangerous.

3:The cost of disposal may increase due to the amount and toxicity of the sludge, and the difficulty of dewatering it.

What is electrochemical coagulation?

Electrochemical coagulation has recently made a more optimized entrance, onto the wastewater treatment scene. This procedure entails providing a certain amount of power to a number of metallic media, after any necessary pH adjustments. Either the anodes and cathodes are made of the same material, or they are made of separate materials.

Depending on the composition of the influent water, this substance is tuned. Two of the materials that can be employed in this technique are iron and aluminium. During oxidation, the electrodes release charged ions into the solution, which causes the particles in the solution to become less stable.

Pros of electrochemical coagulation

1: The electrocoagulation method is simple. Since, there aren't many moving parts, it may be watched remotely with little supervision and upkeep.

2: If necessary, the procedure may also usually be changed, to account for different particle concentrations with little effort.

3: The EC procedure can in some circumstances, address numerous pollutants with a single system and treatment pass.

4: Smaller volumes of sludge, usually non-hazardous, easily dewaterable, and less expensive to handle and dispose of, are produced as a result of the absence of conventional chemical addition.

Cons of electrochemical coagulation

1: The pH of an EC system may need to be adjusted with the addition of acids or bases, hence, it is not entirely additive-free.

2: The electrodes are also sacrificial by nature of the operation, and will deteriorate over time, necessitating replacement.

3: It can clean plates using a CIP procedure, which includes an acid cleaning cycle.

4: The process's nature necessitates electrical power as well.

5: Even, while it might not need much at once, running costs may rise in some regions of the world, where power may be more expensive.

How can we assist?

Netsol Water believes that adopting environmentally friendly, non-chemical methods of water treatment has enormous potential. For municipal and commercial water and wastewater treatment applications, we are happy to develop, engineer, and provide our Netsol’s’ specialist,electrochemical treatment systems and UV disinfection systems.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.